What Is a Ceramic Substrate?

A ceramic substrate is a substrate made of ceramic, which forms the wiring of a printed wiring board or is an insulating board on which components are placed.

Uses of Ceramic Substrates

Ceramic substrates are used in printed wiring boards incorporated in heat dissipation products and high-frequency measuring instruments, etc., as they are used in high-temperature environments and as printed wiring boards become smaller. Specific applications are as follows:

- Heat Dissipation Products

High-power LED lighting equipment, laser processing equipment, deep ultraviolet irradiation equipment

Satellite communication equipment, high-frequency measuring - Equipment

Base station antennas, ETC, RF modules, various radars - Automotive Products

Automotive LED lamps, automotive control components - Electronic Components

Peltier elements, piezoelectric sensors, LEDs, laser diodes, GAN modules, high temperature, acceleration, cycle, SiC power - Semiconductors

High-frequency mobile communication equipment

IoT communication equipment, antennas and filters, voltage controlled oscillators (VCOs), temperature compensated crystal oscillators (TCXOs)

Characteristics of Ceramic Substrates

Ceramic substrate is made of ceramic and its characteristics are similar to those of ceramics. Typical ceramics that form ceramic substrate include alumina substrate, alumina zirconia substrate, aluminum nitride (AlN), and silicon nitride (Si3N4).

These are materials with excellent mechanical strength, electrical insulation, corrosion resistance, heat resistance, and thermal conductivity, and the substrates have the same characteristics.

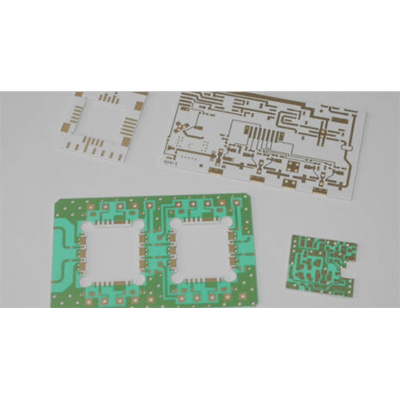

Types of Ceramic Substrate

There are three types of printed wiring boards with wiring patterns, etc. formed on insulating substrates made of ceramics: high-temperature ceramic substrate, low-temperature ceramic substrate, and thick film ceramic substrate.

1. High-Temperature Ceramic Substrate

High-temperature ceramic substrate is a substrate on which high-temperature co-fired ceramic (HTCC) circuits are formed. First, an insulating plate, which serves as the substrate, is manufactured using ceramic raw materials formulated for high temperatures. Next, metal circuits such as tungsten and molybdenum are formed on the insulating plate, and the laminated substrate is fired at high temperature to form a High Temperature Ceramic Substrate.

2. Low-Temperature Ceramic Substrate

Low-temperature ceramic substrate is a substrate made of low- temperature co-fired ceramics (LTCC). They are usually manufactured as multilayer substrates.

First, ceramic powder, glass, and binders are mixed to form a sheet. Through holes are made at necessary locations to connect multiple layers, and a wiring pattern is printed and formed to create a single layer. After several layers of different wiring patterns are created and stacked, the LTCC wiring substrate is completed through the firing process.

3. Thick-Film Ceramic Substrate

Thick-film ceramic substrate is a substrate in which electrical circuits are formed by printing conductor or resistor paste on an insulating substrate, and is characterized by the relatively thick film thickness of the conductor.

Other Information on Ceramic Substrate

1 Ceramic Substrate Made of High-Purity Alumina Material

Ceramic substrate is produced by mixing and firing thermally conductive ceramic powder with organic binder and other materials. When high-purity alumina material is used in this process, the fired ceramic has few pores and a very smooth surface because the alumina material is a fine particle.

This means that the material has excellent adhesion to thick films and thin-film materials, and has stable characteristics when used as a printed wiring board. Also, because they are fine particles, their size does not change after firing, and they have very good external characteristics such as dimensional variation, warping, and bending. They also have high heat dissipation and heat resistance, and are physically and chemically stable even under high heat environments.

2. Semiconductor Packages Using Ceramic Substrate

Heat generation associated with the high integration of semiconductor devices is an important issue, and alumina ceramic substrate with high heat dissipation is used. However, this is not always sufficient to meet the high requirements of today’s semiconductor devices. In recent years, aluminum nitride and silicon carbide have been attracting attention as new ceramic materials for semiconductor packaging that can replace alumina ceramic substrate.

Aluminum nitride is not a natural ceramic material and has excellent thermal conductivity, with a theoretical value of 320 W/m-K. In reality, however, it is difficult to improve the raw materials, burnout, and heat resistance. In reality, improvements in raw materials, selection of sintering aids, and sintering conditions have resulted in the practical application of a thermal conductivity of about 180 W/m-K.

In silicon carbide ceramics, it has become clear that if beryllium oxide is used as a sintering aid, it can be used as an insulator with high thermal conductivity, and it is now attracting attention as a substrate material.