What Is an X-ray Inspection System?

X-ray inspection equipment are devices that can accurately identify elements and hazardous substances in areas invisible to the eye without destroying the object.

X-ray inspection equipment are devices that can accurately identify elements and hazardous substances in areas invisible to the eye without destroying the object.

Based on the transmitted image obtained by irradiating X-rays to the inspected item, the invisible internal conditions are inspected and evaluated.

Since it can see through the inside of a product, which cannot be photographed by a visible light camera, this equipment is indispensable for maintaining high quality in manufacturing, including measures to prevent contamination by foreign matter and hazardous substances.

Applications of X-ray Inspection Systems

Today, X-ray inspection systems are used not only in the manufacturing and processing of medical, food, and electronic parts, but also in the construction and aviation industries.

Examples include X-ray imaging at hospitals and baggage checks at airports.

In the medical industry, they are used for endoscopes, CT scanner systems, digital ray systems, and in research fields such as animal research.

Principle of X-ray Inspection Systems

X-rays are a form of radiation consisting of photons that have high energy and propagate in flux, and “electromagnetic rays” with short wavelengths. X-rays are a type of radiation.

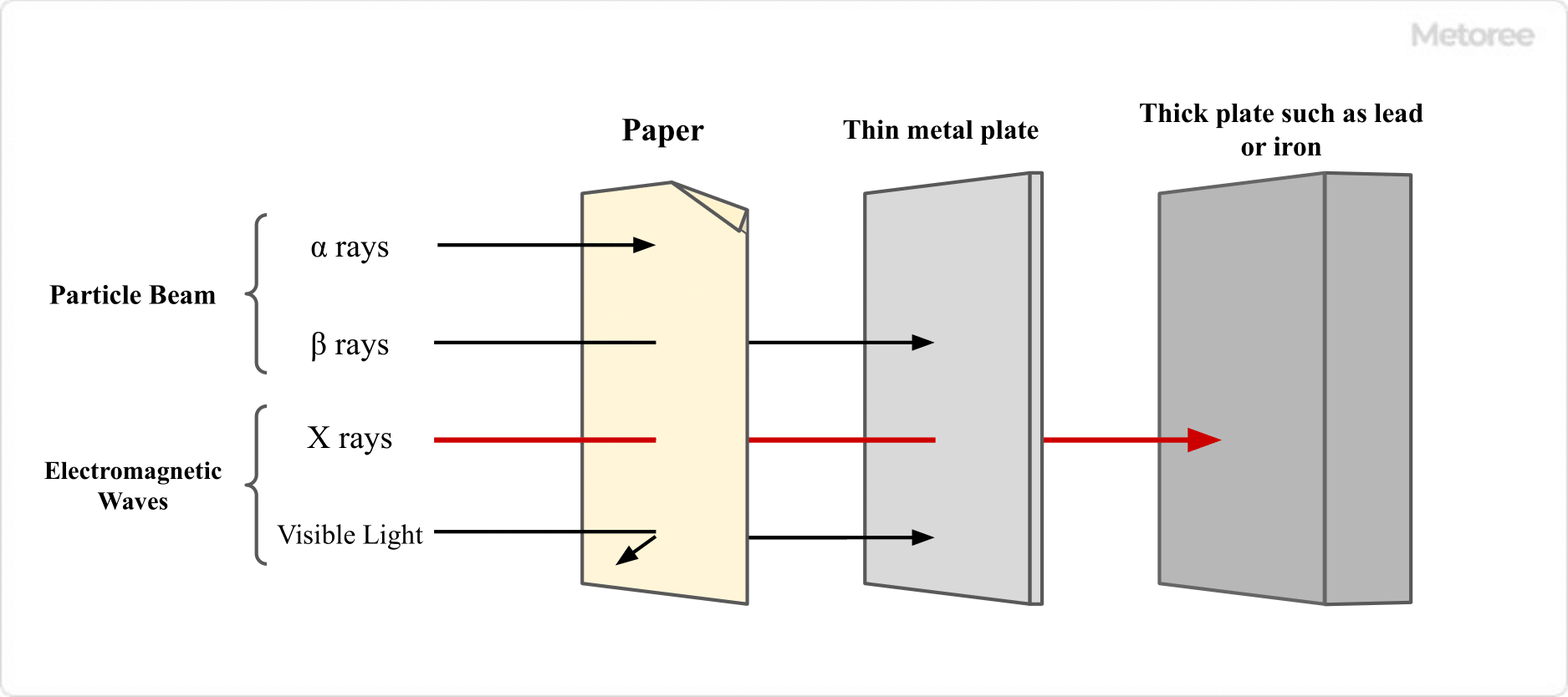

There are five types of ionizing radiation, including X-rays: alpha rays, beta rays, gamma rays, X-rays, and neutron rays.

Among these, X-rays, along with gamma rays, are electromagnetic waves with very short wavelengths, making them highly penetrating through matter by passing between atoms that make up matter.

However, they can be blocked by thick plates of lead or iron.

When X-rays collide with electrons orbiting the nucleus of a material, various interactions such as the photoelectric effect and inelastic scattering occur.

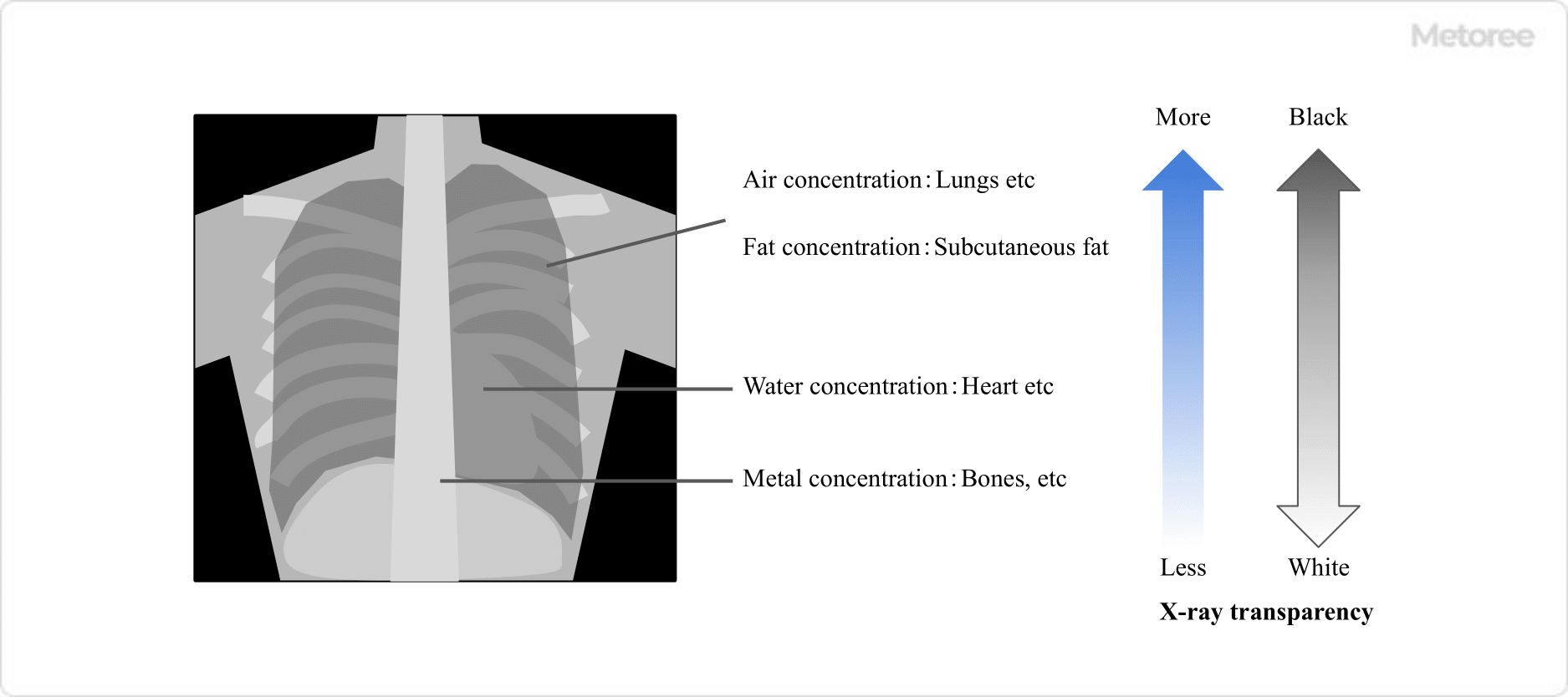

X-rays that do not undergo these phenomena penetrate the material and become transmitted X-rays, and the more transmission there is, the darker the image appears.

Conversely, areas that are attenuated appear bright and white. In fact, images taken using X-rays are black and white, where the shade is determined by the amount of transmitted X-rays.

In general, it is known that the intensity of transmitted X-rays is determined by factors such as the atomic number, density, and thickness of the object material.

Miniaturization of X-ray Inspection Equipment

X-rays, discovered by Roentgen in 1895, are electromagnetic waves with wavelengths of approximately 1 pm – 10 nm.

They are also a form of radiation, and are used in X-ray photography for medical examinations and nondestructive testing, as well as in the analysis of crystal structures using the diffraction phenomenon.

Most people’s conception of X-ray inspection equipment is that it is a large-scale device that takes pictures of the entire body.

However, today, a wide variety of portable X-ray inspection systems are available, and they are mainly used for nondestructive testing at factories and construction sites.

Their features are often referred to as portable nondestructive testing equipment that can be easily used at any time and place.

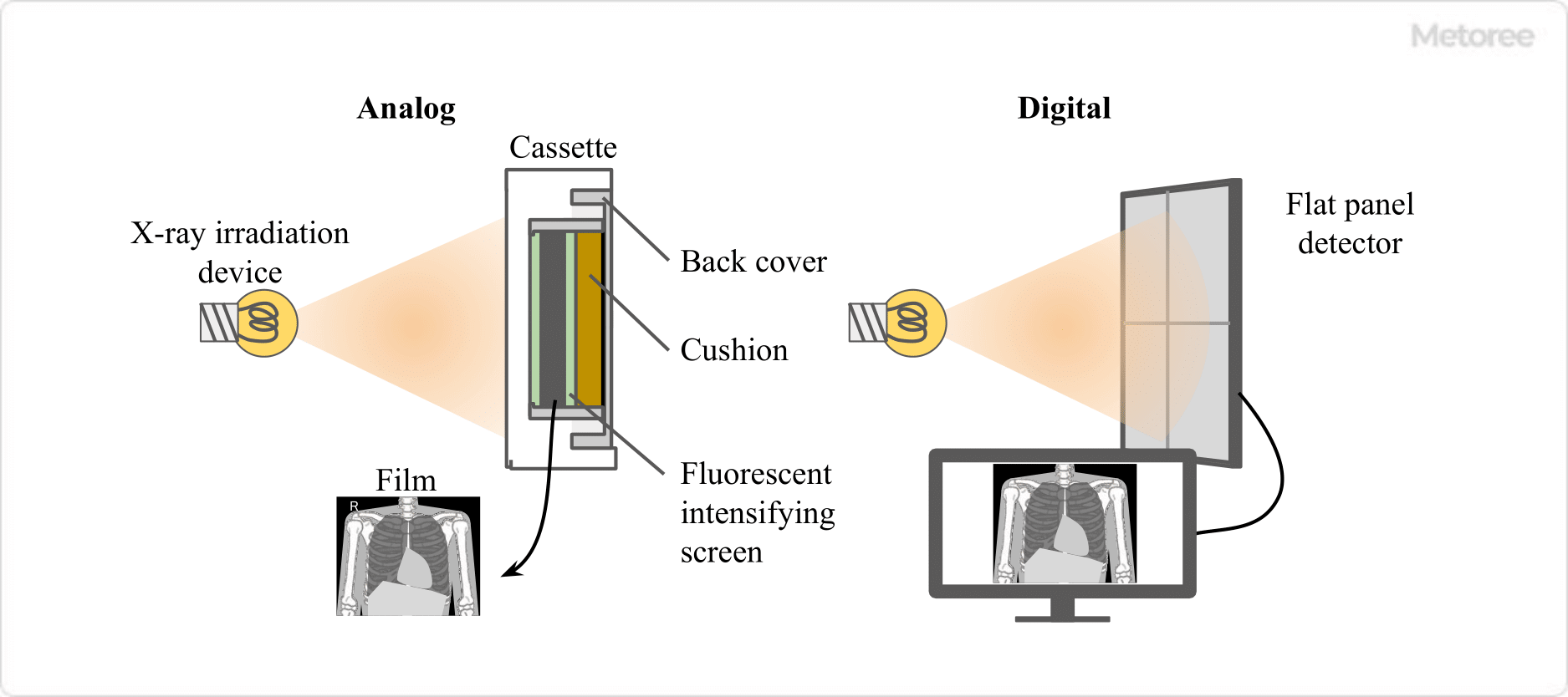

It is a device that inspects all kinds of objects with X-ray images by combining a polarized X-ray and a high-precision digital detector.

Without destroying the object to be inspected, it is possible to check for cracks, fissures, corrosion, and other abnormalities, as well as the finish of welded parts.

X-ray inspection systems are highly mobile and ideal for completion and periodic inspections at factories and construction sites. However, since they are a source of ionizing radiation, they should be handled with care.