What Is an IGBT Module?

An IGBT module is a highly integrated module that combines multiple IGBTs (Insulated Gate Bipolar Transistors) into a single module.

An IGBT module is a highly integrated module that combines multiple IGBTs (Insulated Gate Bipolar Transistors) into a single module.

IGBTs were invented in Japan in the late Showa period (1926-1989) by combining the advantages of the conventionally used base current control type bipolar transistor and the gate voltage control type field-effect transistor (FET), whose weaknesses were improved, with device structures and process innovations.

Initially called insulated gate bipolar transistors, they were later called IGBTs, an acronym for “insulated gate bipolar transistors.”

Uses for IGBT Modules

Although today it is called power electronics technology, IGBTs were then a special world technology for specialists only that had not seen the light of day very often. However, the use of IGBT Modules, which are stored inside inverter air conditioners and other electrical appliances, has expanded dramatically, especially in high-power products, due to the use of inverters (energy saving through power conversion technology) and the use of compact, high-efficiency modules for components.

Today, it is a well-known fact that IGBTs and their modules are commonly used in products that require large amounts of power.

Principle of IGBT Modules

The IGBT is an epoch-making power semiconductor created in Japan that uses a conventional bipolar transistor structure for the parts where large current flows, and switches the base part, which is the control part of the bipolar transistor, to a FET gate circuit structure (previously used only in signal circuits for weak power systems, and capable of high-speed control with low loss). This is a revolutionary power semiconductor created by Japan. The IGBT Module is a compact and highly functional module that contains multiple IGBTs, including diodes for protection circuits and ICs for driving circuits.

IGBTs also exist as discrete components, and it is possible to build a circuit similar to that of a module using discrete components. However, when a circuit is built as a single item, the board size is generally twice or more the size of a module, and there are concerns about the possibility of signal delays, instability, and other malfunctions due to the wiring patterns on the board, which can cause many problems for the user.

In contrast, modularization allows high-density wiring and reliability through improved heat dissipation, making it relatively easy for users to use IGBTs in their own products. This is the biggest advantage of using IGBT Modules instead of IGBTs alone.

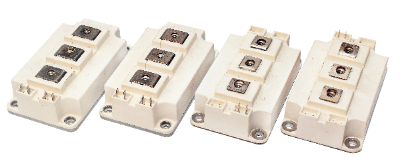

As a practical example of an IGBT module, let us illustrate a module containing six IGBTs that drive a mainstream brushless motor. The module is characterized by the fact that the module package is filled with insulating material, and the wiring inside the module is as short and thick as possible to reduce electrical losses.

A heat sink is also added to the module to enable operation of the IGBTs with clearly lower losses and higher heat dissipation than when mounted on a board as a single unit. Thus, the modularization of IGBTs enables both high-efficiency operation and downsizing of equipment, compared to the use of single components (discrete).

Other Information on IGBT Modules

Evolution of the IGBT Module (IPM)

IGBT modules are now also called IPMs (Intelligent Power Modules), which contain high-voltage drivers that used to be external to the

IGBTs, and the technological innovation is still ongoing. In order to improve the performance and functionality of conventional modules that integrate multiple IGBTs in a single package, IGBT modules are often called IPMs, which integrate IGBT-specific driver ICs and various protection circuit ICs for overcurrent and overheat protection together with the IGBTs, as well as compact and heat-dissipating measures.

IPM is a field in which Japan, the creator of IGBTs, is leading the world as a technology in which it excels. The field of power electronics using new semiconductor materials such as SiC and GaN, which are wide band gap semiconductors, has been booming in recent years, and there is a movement to replace IGBTs on Si substrates with SiC-MOSFETs and GaN-FETs, which have superior characteristics, as in the electric vehicle field, such as EVs. There is also a movement to replace IGBTs on Si substrates with SiC-MOSFETs and GaN-FETs, which have superior characteristics.

However, these new semiconductor material substrates are still not as good as Si substrates in terms of wafer size, cost, and manufacturing capacity, so for the time being, devices and modules will continue to be separated for product applications.