What Is a Bearing Roller?

Bearing rollers are either assembled with bearings and a hollow shaft or with bearings and a built-in bolt in the center.

Those assembled with a hollow shaft mainly insert the shaft in the center and use the bearing outer diameter as the guide section.

Those with a bolt built into the center section are mainly used by inserting the shaft into a tapped hole and using the bearing outer diameter as the guide section.

The guide part is used as a workpiece transfer guide or as a roller for transfer.

Similar parts include roller followers and cam followers that both use needle bearings in the bearing section.

Uses of Bearing Rollers

Hollow shaft rollers have a hollow shaft inserted into the bore of the bearing and can be fixed at any position on the shaft. Uses are as follows:

- Multiple bearing rollers on a single shaft and multiple parallel shafts of such rollers are used as rollers for workpiece conveyance.

- Two bearing rollers are placed on one shaft and used as tensioners by pressing a thin-film workpiece by the outer diameter surface of the bearing.

Those with built-in bolts have a structure that can be easily fixed by inserting bolts into the inner diameter portion of the hollow shaft and into the tapped holes. Uses are as follows:

- Use as a guide for workpiece conveyance by arranging several bearing rollers at equal intervals, like guardrails.

- Two bearing rollers are installed at an arbitrary distance in the same direction, and a thin film or belt is passed through the rectangle connecting the outer diameters of each roller to be used as a tensioner to hold the roller from the outside.

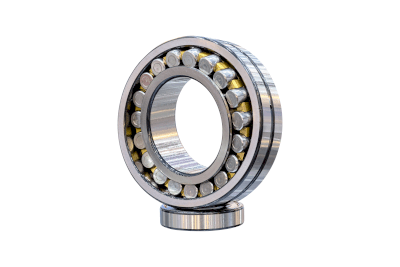

Principle of Bearing Rollers

For hollow shafts, a ring material with a hole in the center is inserted into the inner diameter of the bearing, and a retaining ring is assembled at the inserted end. The shoulder of the ring material and the retaining ring restrain the width of the bearing so that the bearing will not come loose from the ring material. The ring material can be tightened by bolts or by other means to reduce the inner diameter, allowing the bearing to be secured at any location on the shaft.

Because it uses bearings, it rotates smoothly even under high loads and at high speeds.

For those with a built-in bolt, the bolt is built into the inner diameter of the hollow shaft. Since the head of the bolt has a hexagonal hole or the like, it can be easily mounted in any desired location by machining a tapped hole in the part where you want to mount it.

In addition to the type in which the ring material is inserted into the inner diameter of the bearing, another type is available in which the ring material is press-fitted into the outer diameter of the bearing.

The outer diameter of the ring material can be made into a groove or a convex radius to create a tensioner or guide suitable for the shape of the workpiece.