What Is a Runout Gauge?

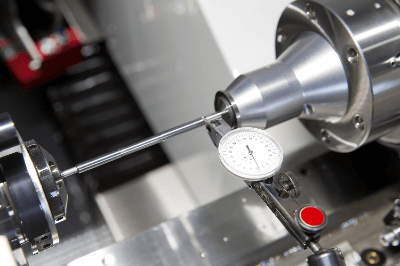

A runout gauge is a measuring stand to which a dial gauge is attached to make comparative measurements of two or more objects. It is usually used to measure the runout of shafts, gears, pulleys, etc.

The measurement itself is usually done by a contact method using a dial gauge. The runout gauge is positioned as a measuring stand to perform the measurement.

Uses of Runout Gauges

Runout gauges are mainly used as fixtures for comparative measurement of two or more objects.

Specific applications include the following:

- Fixing measurement objects for sampling inspection in the gear machining process of pulleys, etc.

- Fixing an object to be measured for comparative measurement of motor shafts

- Fixing of laminated cores for squareness measurement

The following two methods of measurement exist:

- Non-contact type using a sensor or displacement meter

- Contact type using a dial gauge

Principle of Runout Gauges

A runout gauge is a measuring stand used to fix an object to be measured in order to measure the runout of shafts, gears, pulleys, etc.

The unit for fixing the object to be measured is attached to the top of the high-precision, leveled base on both sides, and the jig fixing part is a general-purpose part that can be replaced according to the shape of the object to be measured.

There are two types of measurement methods after the fixture is fixed, and they are classified into the non-contact type using a sensor or displacement meter and the contact type using a dial gauge.

Since the majority of measurements are made by the contact type using dial gauges, it is necessary to make improvements in on-site operations to minimize errors caused by differences in measurement by the different measurers.

Typical examples of use include fixing applications for sampling inspection of workpieces in the manufacturing process.