What Is a Diamond Core Drill?

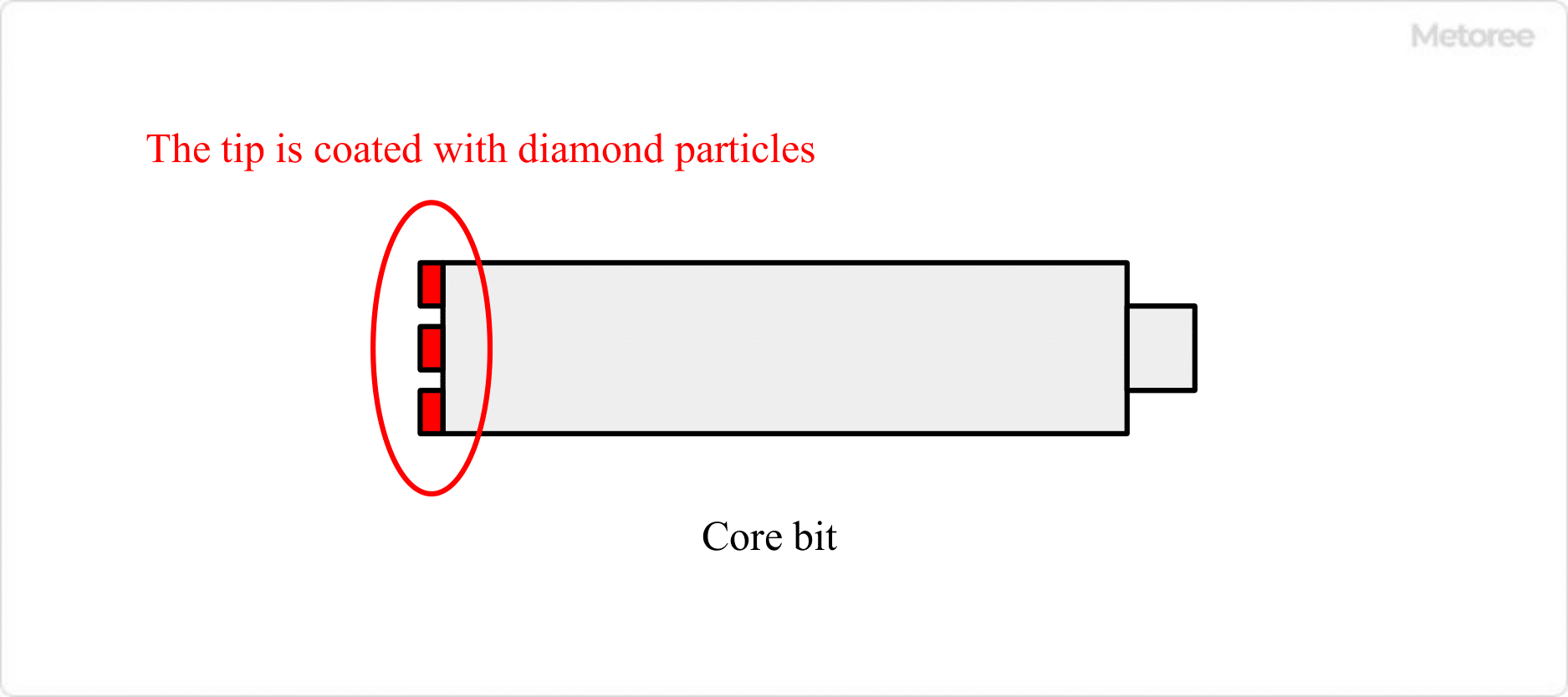

Figure 1. Structure of core bit

A diamond core drill is a tool that uses a core bit whose tip is coated with diamond particles to drill holes in hard materials.

Compared with ordinary drills, it has higher cutting power and superior durability. When drilling holes in hard materials, such as concrete, strong force such as vibration or blows are required, resulting in loud noise.

Diamond core drills, however, use only rotational force when drilling holes, which reduces noise.

Uses of Diamond Core Drills

Diamond core drills are used for construction, remodeling, infrastructure development, rock drilling, as well as for processing stone and glass. Because of their high cutting power and durability, diamond core drills can be used to drill holes in hard concrete floors and walls to run pipes such as water and gas lines, and to excavate bedrock to conduct geological surveys.

Diamond core drills are also useful for hard but brittle materials such as stone, glass, tile, and ceramic. Working at the proper speed and pressure, drilling can be performed while preventing cracking and chipping.

Principle of Diamond Core Drills

The core bits used in diamond core drills are coated with extremely hard diamond particles at the tip. This makes it possible to drill through hard materials such as concrete. Furthermore, diamond is highly durable, so it does not deteriorate easily even after prolonged use or large amounts of work.

Another feature of diamond core drills is that they do not use striking force like hammer drills, but only rotational force. This reduces vibration and noise, and allows drilling of even brittle materials such as stone and glass without damaging them.

How to Select a Diamond Core Drill

The following four points should be considered when selecting a diamond core drill.

1. Size

Diamond core drills come in various sizes, from small to large. It is important to select the appropriate size according to the diameter of the hole to be drilled.

2. Pole Base Type / Handy Type

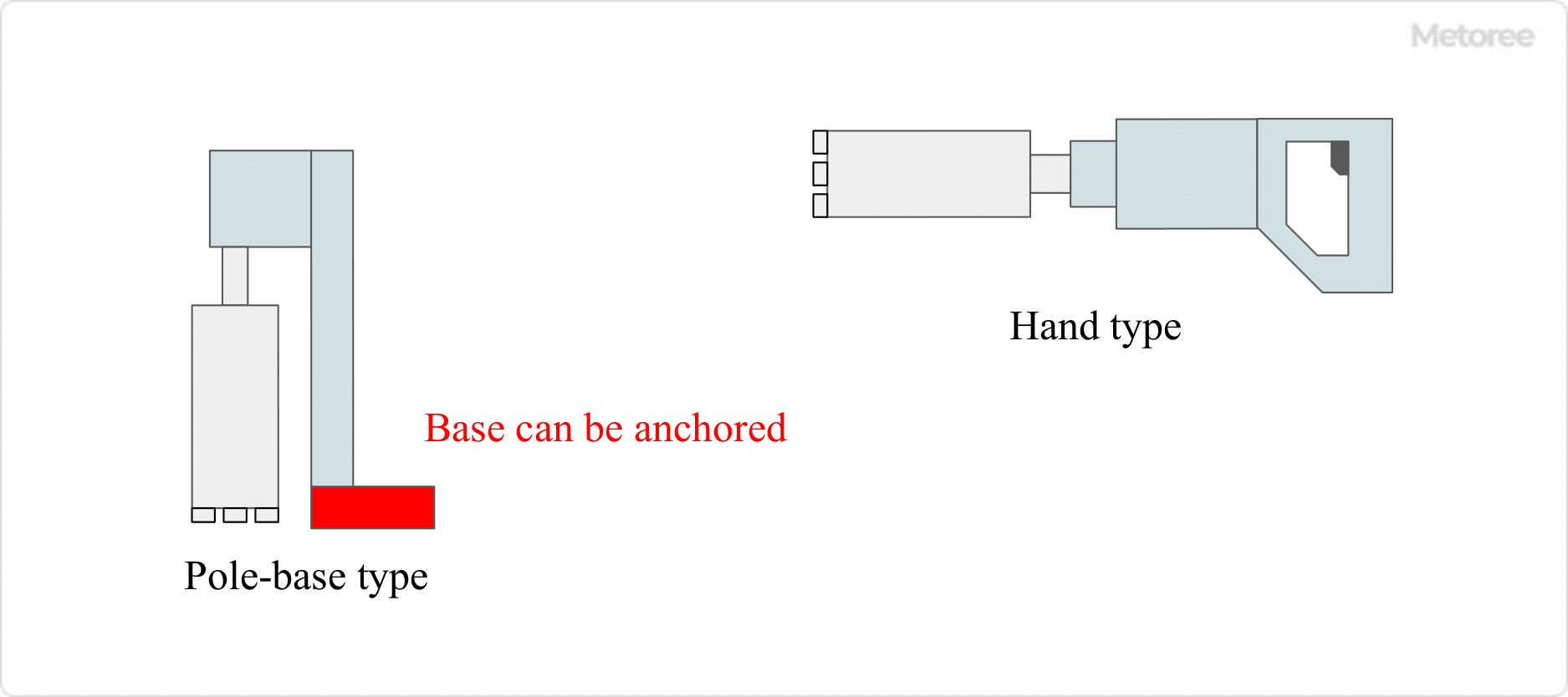

Figure 2. Pole-base type and hand type

There are two types of diamond core drills: the pole base type and the handy type. The pole base type can anchor the base to the floor or wall, enabling stable drilling of large or deep holes.

The handy type is suitable for drilling small or shallow holes efficiently. Hybrid types that can be used for both the pole base type and the handy type are also available.

3. Wet Type / Dry Type

There are two types of diamond core drills: wet type and dry type. The wet type reduces frictional heat, which prevents deterioration of the core bits. Wet type drills use water and require curing and cleaning.

The dry type does not use water and can be used just like a regular drill. However, the core bits tend to deteriorate due to frictional heat, and dust is generated.

4. Mounting Screw Standard

Diamond core drills have a screw-type core bit attachment, and there are several standards, such as A-rod, C-rod, and M27, so it is important to select the drill body and core bit to match the screw standard.

If you want to use a different standard, there are reducers that can convert the thread standard.

Other Information on Diamond Core Drills

How to Use Diamond Core Drills

The use of diamond core drills can be roughly divided into three steps: marking, preparing the drill, and drilling.

1. Marking

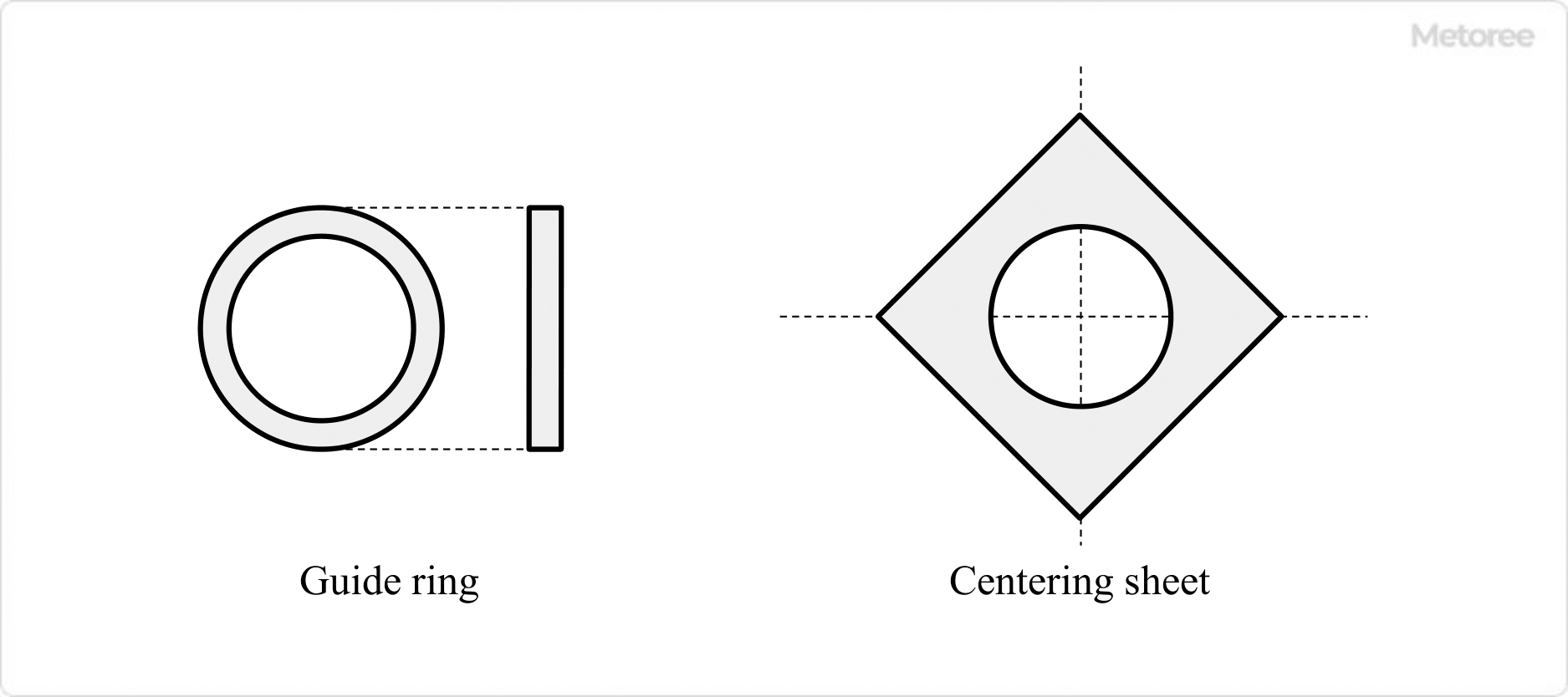

Figure 3. Guide ring and centering sheet

Before drilling, mark the drilling position to ensure accurate drilling. Some products come with jigs such as guide rings and centering sheets.

2. Preparation for Drilling

Select an appropriate core bit according to the hardness of the material to be drilled and the size of the hole. Low speed and high torque settings for the drill are appropriate for hard materials.

3. Drilling Operations

First, a 3 to 5 mm guide groove is made using a jig and center pin. After the guide groove is made, remove the jig and center pin and move on to the full-scale drilling operation.

It is essential to maintain appropriate rotational speed and pressure to avoid damaging the object. When drilling is about to be completed, reduce the rotational speed and pressure for safety.

Core bits become hot due to friction heat. To avoid burns, use caution and wear protective equipment, such as safety glasses, dust masks, and earplugs, depending on the work environment.