What Is a Cooling System?

Cooling Systems are devices, equipment, or electronic equipment that are used to reduce temperature increases. Cooling Systems can be broadly classified into two types: water-cooled, which uses water to cool, and air-cooled, which uses air to cool.

Cooling Systems are devices, equipment, or electronic equipment that are used to reduce temperature increases. Cooling Systems can be broadly classified into two types: water-cooled, which uses water to cool, and air-cooled, which uses air to cool.

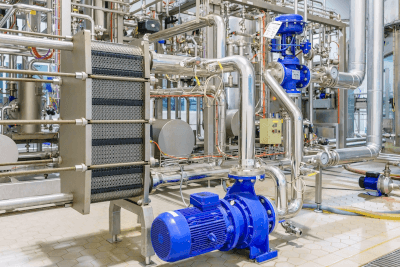

Among the water-cooled types, there are two types: one uses industrial water and the other uses a chiller system that recirculates water that has been heated through the equipment by cooling it again.

Air-cooled systems absorb heat and dissipate it to the atmosphere through contact with heat-conductive metal or air, or use an electronic device called a Peltier element to transfer heat.

Uses of Cooling Systems

Air-cooled heat exchangers are used in cooling systems of petroleum complexes and waste incineration plants, where large amounts of heat are generated. An air-cooled heat exchanger is cooled by flowing the fluid to be cooled and blowing air with a fan.

Water-cooled heat exchangers are used to efficiently cool metal parts. By drilling holes in the parts to be cooled and passing cooling water through them, the heat of the metal parts can be taken away directly. They are used for camera noise reduction and brazing machines that generate high temperatures locally.

Peltier elements may be used in areas where water or air cannot be circulated or where cooling to below 0°C is desired.

Principle of Cooling System

Cooling Systems using Peltier elements can cool objects down to below 0°C (32°F).

Peltier elements cool by utilizing the thermoelectric effect, a phenomenon in which heat is absorbed and dissipated at the metal junction when two different metals are connected in series, and an electric current is applied to them. Since the direction of heat flow can be controlled by the direction of current applied to the Peltier element, it can be used not only for cooling but also as a heat source.

Peltier elements can take away a large amount of heat by stacking multiple layers, but it is also important to dissipate the heat taken away efficiently. In general, heat is dissipated using aluminum heat-dissipating fins and heat exhaust fans. However, in order to improve efficiency, the number of units that use heat pipes and heat conductive sheets in combination is increasing. Not only the heat absorption power of the Peltier but also the amount of heat that can be exhausted is important.

Recently, flexible Peltier elements have been developed that can adhere to curved surfaces for efficient cooling.