What Is Abrasive Blasting?

Abrasive blasting, a surface treatment method, is widely used for metals. It involves directing abrasive materials onto the surface of products or materials using compressed air or similar techniques. This method is effective for smoothing surfaces, removing rust, coatings, scales, and creating a fine, uniform surface texture.

Abrasive blasting is adaptable to various materials, including metals, resins, and glass, and is especially useful for items with complex shapes. However, it may not be suitable for achieving mirror finishes due to the surface irregularities it creates.

Uses of Abrasive Blasting

Abrasive blasting is primarily used for cleaning, rust removal, paint stripping, and deburring. Its versatility, adjustable blasting intensity, and the availability of various abrasive materials make it suitable for a wide range of applications. It is also employed for peening to strengthen metals and for applying matte finishes for aesthetic enhancement.

Principles of Abrasive Blasting

Abrasive blasting functions in three main ways:

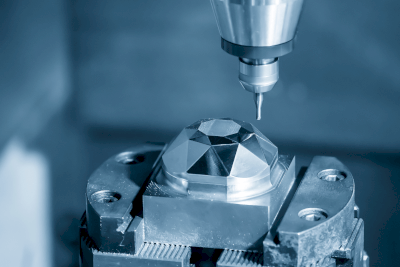

1. Cutting

This method, which includes cutting, roughing, grinding, and polishing, selects abrasive materials based on the desired cutting amount and area. Hard and sharp-edged abrasives are preferred for large-scale cutting in a short time.

2. Removal

This involves removing debris, oil, dirt, coatings, burrs, and oxide films from the surface. Softer abrasives like nylon or copper are used to prevent product damage.

3. Modification

This process alters only the surface properties, using spherical abrasives to avoid material removal.

Types of Abrasive Blasting

Abrasive blasting includes:

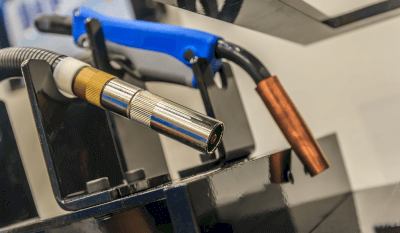

1. Sandblasting

Sandblasting uses compressed air with abrasives for surface processing. Traditional sandblasting used silica sand, but now alternatives are preferred due to health concerns. This method is versatile, accommodating a variety of abrasive materials.

2. Shot Blasting

Shot blasting employs a high-speed wheel to project abrasives. Using steel shots, this method offers a broader range of abrasives than air blast and is efficient but produces shallower surface textures.

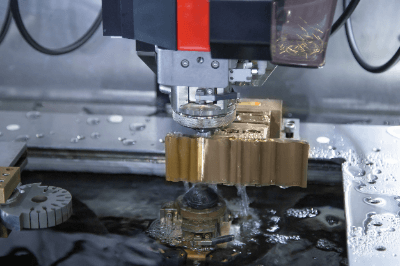

3. Grit Blasting

Grit blasting, similar to shot blasting, uses angular grains for higher abrasive power. Suitable for complex shapes, it is more expensive than sandblast and shot blast.

How to Choose an Abrasive Blasting Approach

Choosing the right blast processing equipment and materials is critical. Incorrect choices can lead to surface irregularities, deformation, or residual material on the surface. Careful consideration of material types and processing order is essential.