What Is Wire EDM?

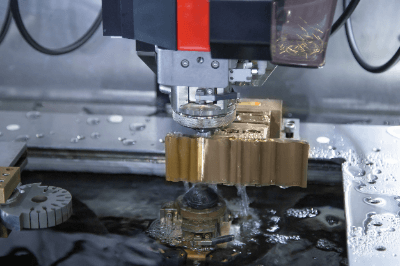

Wire electrical discharge machining (EDM) is a method where an electrical current passes through a brass wire to cut materials using discharge heat. This technique does not involve direct contact between the wire and material, resulting in clean cuts and enabling precision machining to a few micrometers. It accommodates cutting widths in materials ranging from as thick as 400 mm to as thin as 0.02 mm.

Suitable for cutting conductive materials like iron, stainless steel, copper, brass, and aluminum, Wire EDM cannot process non-conductive materials.

Uses of Wire EDM

Wire EDM is used in metal cutting and precision machining for a variety of thicknesses. It’s applied in fabricating small components in devices like smartphones and household appliances, as well as in larger machinery parts.

Its precision makes it ideal for mold manufacturing and intricate shapes. The wire-cutting process streamlines steps compared to traditional machining, allowing for efficient one-stroke cutting in sheet metal processing.

Principles of Wire EDM

Wire EDM operates in a tank filled with insulating water or oil to cool the wire and prevent it from being cut by heat. The electrical discharges between the electrified wire and the material enable melting and cutting without direct contact at extremely high temperatures.

This method offers the advantages of precision cutting across a wide range of conductive material thicknesses, using wires typically between 0.10 mm and 0.30 mm in diameter. It produces no burrs or chips, reducing the need for additional processing. However, limitations include slow processing speeds and the inability to process non-conductive materials or perform certain machining tasks like groove or pocket machining due to the vertical stretching of the wire during processing.