What Is a Wire Electrode?

A wire electrode is a tool used in wire Electrical Discharge Machining (EDM) machines.

During EDM, a voltage is applied between the workpiece and the tool electrode, resulting in an electrical discharge phenomenon. The high heat generated during this process (approximately 7,000°C) gradually heats and melts the workpiece.

The tool used in this process is a wire electrode, typically with a diameter ranging from approximately 0.05 to 0.3 mm, making it an extremely thin metal wire. The primary material used for electrode wires is usually brass, which is an alloy of copper and zinc.

Uses of Wire Electrodes

Wire electrodes are employed for cutting various hard metal parts. EDM can be performed on any hard workpiece that can conduct electricity.

- Special rings processing: Achieving high-precision cuts in special rings using wire electrodes.

- Plate springs: Cutting plate springs in layers using wire electrodes.

- Metal masks: Easily processing metal masks.

- Home appliances and more: Utilized for precision machining of metal components used in home appliances and smartphones. Also, applied for precision parts processing in the aerospace industry.

Features of Wire Electrodes

Wire electrodes employed in wire EDM machines cut the workpiece metal similar to a “hacksaw” through heat generated by electric discharge while continuously feeding the wire as an electrode. The choice of wire diameter depends on the shape and thickness of the metal to be cut or shaped, with wire diameters of 0.1 to 0.3 mm being commonly selected.

The wire diameter must match the die’s diameter used in the electrical discharge machine. If the wire is too thick, it will not pass through the die, and if it is too thin, the electrode wire will sway. Common wire diameters (in mm) include 0.02, 0.03, 0.05, 0.07, 0.10, 0.15, 0.20, 0.25, and 0.30.

The main material for wire electrodes is brass, which is an alloy of copper and zinc, typically with a zinc composition of 35-40%. Brass exhibits good discharge characteristics and is widely used as a general-purpose electrode wire.

Another type of wire electrode is known as “coating wire,” where the surface layer of brass is electroplated with high-purity zinc. The high-purity zinc layer ensures a uniform and smooth finish on the workpiece surface, allowing for high-speed processing.

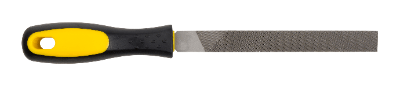

A millsaw file is a specialized file designed for sharpening various metals, including

A millsaw file is a specialized file designed for sharpening various metals, including  Airtight waterproof tape is a very useful tape because it can be cut by hand and is airtight and waterproof. It is often used at construction sites and in interior decorating because it can be applied to walls, ceilings, and other spaces to maintain waterproofing.

Airtight waterproof tape is a very useful tape because it can be cut by hand and is airtight and waterproof. It is often used at construction sites and in interior decorating because it can be applied to walls, ceilings, and other spaces to maintain waterproofing.