Understanding Sheet Metal Scissors

Sheet metal scissors, essential tools in sheet metal processing, facilitate cutting through the action of two crossing blades. They excel at slicing through steel plates, tinplate, and more.

Distinct from standard shears, sheet metal scissors are available in a broad array of sizes and types. Their design features a long grip relative to the blade, which may be back-skived, warped, or threaded to enhance sharpness, enabling significant shearing force. However, their unique design nuances classify them as tools primarily for craftsmen.

Applications of Sheet Metal Scissors

Sheet metal scissors find utility across various sectors due to their versatility. They play a pivotal role in construction and metal fabrication, cutting through steel and aluminum plates, along with wire.

They are commonly used for:

- Auto body part trimming.

- Roofing material and flashing cutting.

- Home DIY metalworking projects.

- Plumbing installations involving metal plate working and sheet metal cutting.

- Jewelry creation.

- Metal furniture and ornament crafting and restoration.

How Sheet Metal Scissors Work

Operating on the leverage principle, similar to regular scissors, sheet metal scissors use the rotation center as the fulcrum, applying force to the handle to shear metal. This force encompasses the linear shear to cut the material, the bending load due to material bending, and the frame friction of the scissors.

Choosing the Right Sheet Metal Scissors

With a multitude of blade shapes and materials offered by various manufacturers, selecting the ideal sheet metal scissors depends on the specific application.

Blade Shape

Blade shapes are primarily categorized into three types, each suited for different cutting needs:

- Straight Blade: Ideal for smooth, even cuts in straight lines.

- Willow Blade: Offers flexibility for cutting straight or curved lines, featuring a pointed tip for ease of cutting and smooth finishes.

- Gouging Blade: Best for creating holes in tin plates and executing sharp curves, perfect for detailed and precise work.

Other variants include corrugated plate cutting scissors and Western scissors with a double-strength structure, enhancing ease of use and achieving finer finishes.

Blade Material

The material is crucial for the scissors’ durability and cutting performance:

- Yasugi Steel: Known for its hardness and composition variety, this steel is a popular choice in many Japanese blades.

- Molybdenum Steel: An upgrade over standard stainless steel, offering prolonged sharpness and excellent rust resistance.

- HSS (High Speed Steel): Known for its hardness and ability to efficiently cut through thick and hard materials while maintaining sharpness over time.

- SLD Steel: Distinguished by its high hardness and toughness, it offers a balanced performance with enhanced rust resistance.

- ZDP Steel: Utilizing powder metallurgy technology, it stands out in hardness, corrosion resistance, wear resistance, and toughness, though its hardness may complicate blade setting and sharpening.

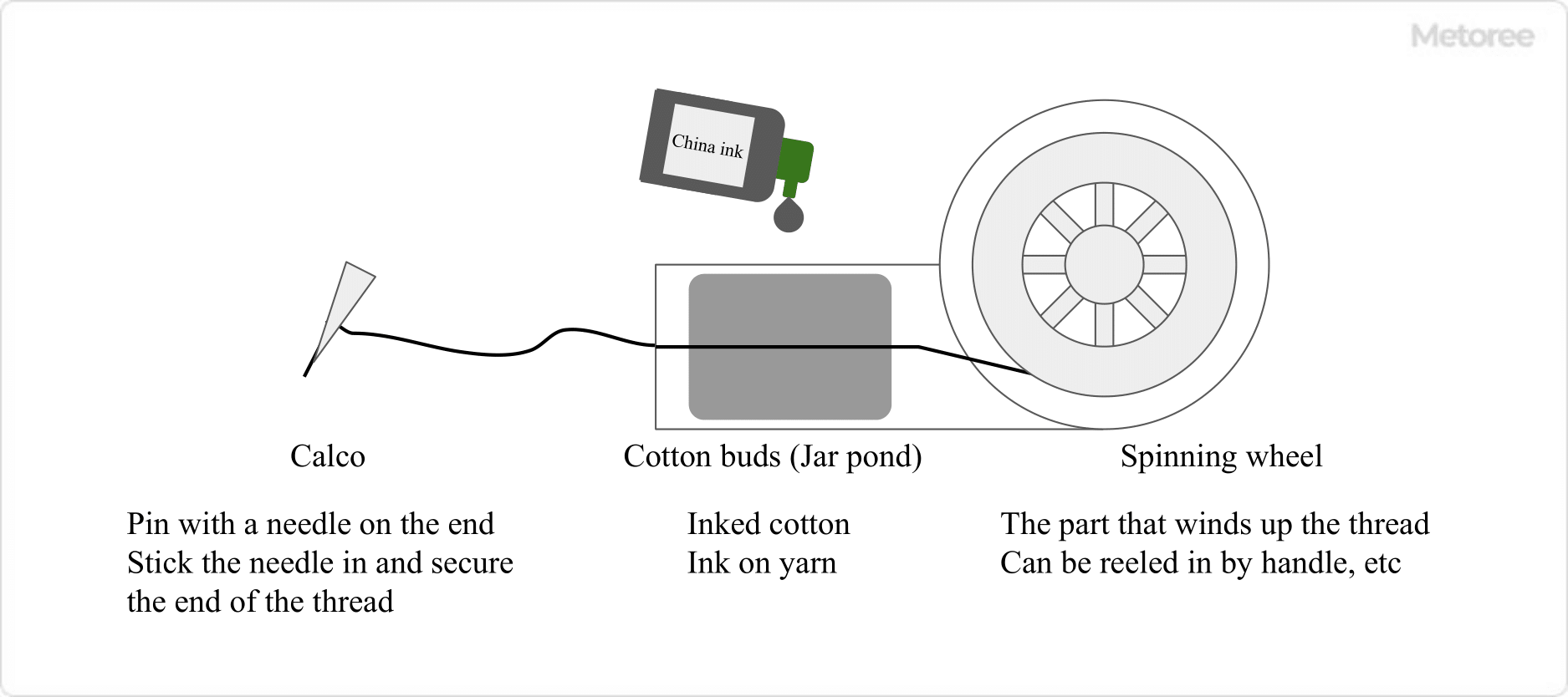

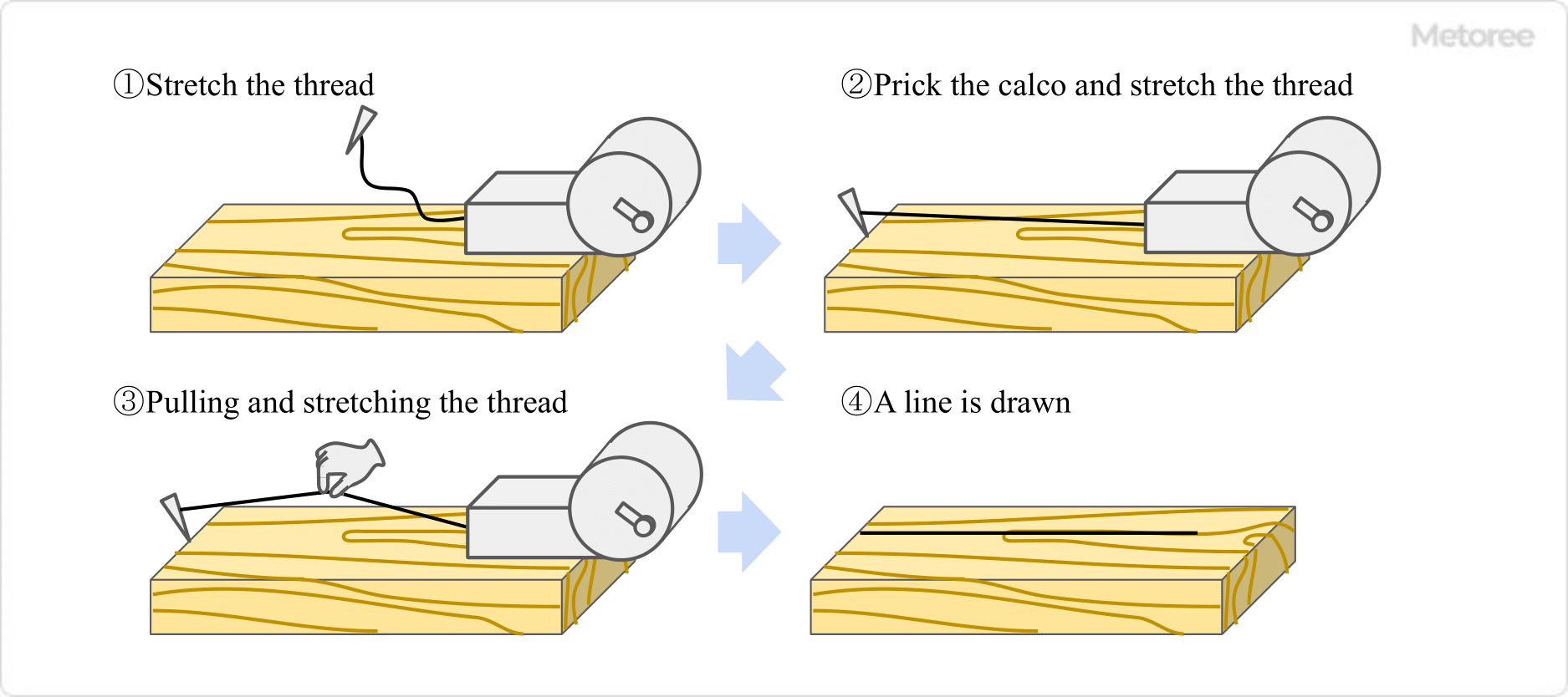

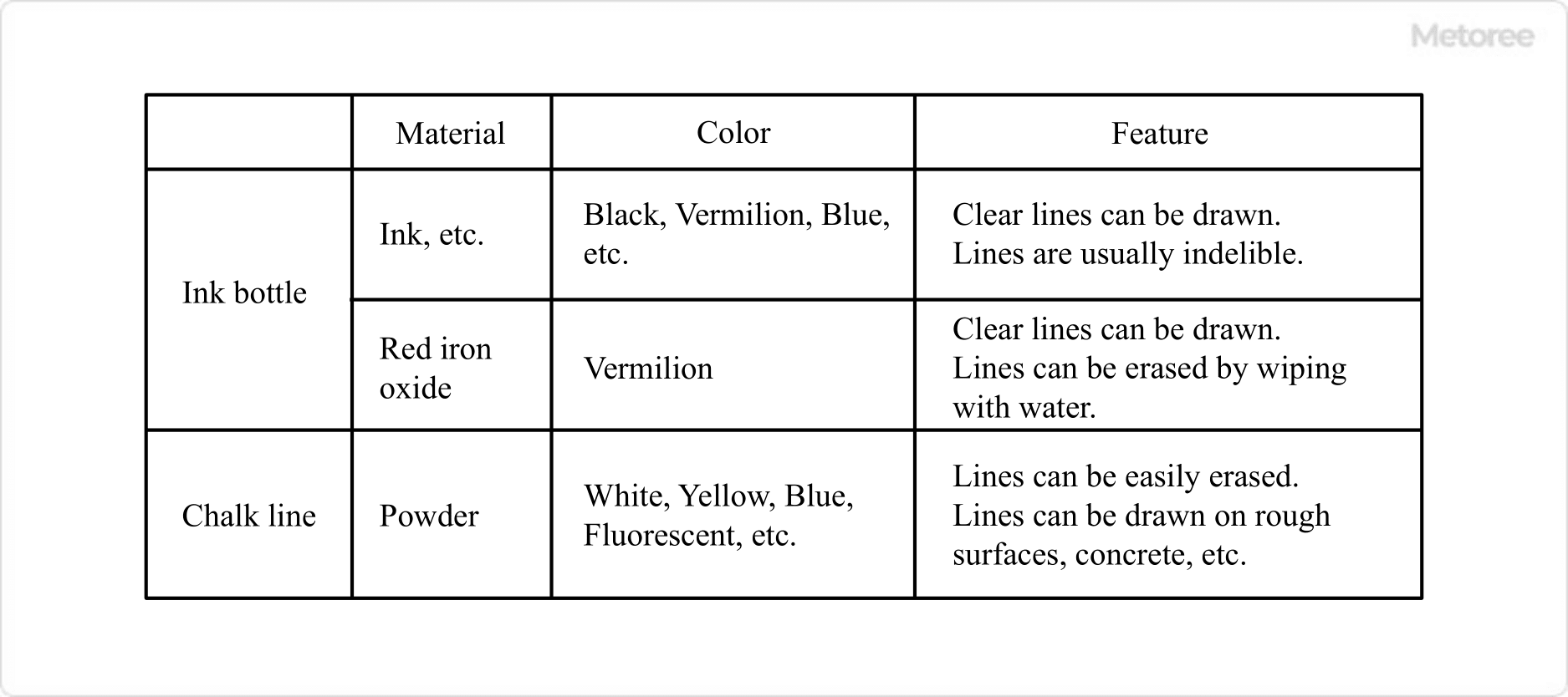

A chalk line is a carpenter’s tool used to draw a straight line on the surface of a piece of wood or other material.

A chalk line is a carpenter’s tool used to draw a straight line on the surface of a piece of wood or other material.

Leveling String is a tool used in construction to mark horizontal lines. It’s typically hooked onto a nail and can be secured into a block or concrete. This string is essential for visualizing straight lines between two points in the air and comes in various colors like yellow and pink for visibility. It is available in different materials and thicknesses.

Leveling String is a tool used in construction to mark horizontal lines. It’s typically hooked onto a nail and can be secured into a block or concrete. This string is essential for visualizing straight lines between two points in the air and comes in various colors like yellow and pink for visibility. It is available in different materials and thicknesses.

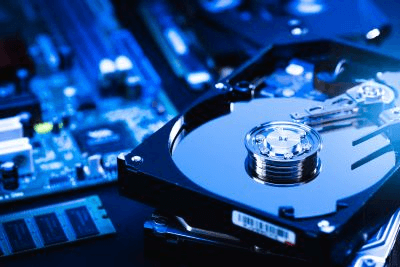

A disk drive is a data storage device consisting of a

A disk drive is a data storage device consisting of a