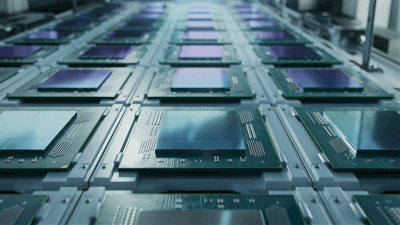

What Is Foundry Machinery?

Foundry machinery refers to a company or service that manufactures elements and integrated circuits on contract in the semiconductor manufacturing industry. Foundries own semiconductor manufacturing equipment and manufacture products on an OEM basis based on data from products developed and designed by semiconductor manufacturers and fabless manufacturers (manufacturers that do not own their production facilities).

This approach is mutually beneficial because the outsourcing manufacturer or fabless company does not need to own the semiconductor manufacturing equipment, which requires significant investment. Meanwhile, the foundry can concentrate on the maintenance and operation of the equipment.

Advantages of Using Foundry Machinery for Semiconductor Manufacturing

The start-up of a semiconductor manufacturing plant involves substantial costs for the introduction of microfabrication equipment. Additionally, semiconductor manufacturing requires an extremely high level of cleanliness, as even the smallest particle contamination is unacceptable. Furthermore, the chemicals, gases, and pure water used in manufacturing must be of high purity, and piping and other equipment must be free of foreign matter. As a result, the maintenance and operation of semiconductor manufacturing facilities also require significant costs.

Outsourcing manufacturing to foundry machinery allows semiconductor manufacturers to avoid the initial investment and maintenance costs of a factory and produce their products promptly. Foundry machinery, with its advanced manufacturing technology and parallel production for multiple companies, achieves high facility utilization rates. This enables the production of high-quality semiconductors at a lower cost.

Because of these advantages, the semiconductor industry today has a division of labor between fabless companies that plan and design products and foundry machinery that performs contract manufacturing.

Contract Manufacturing to Foundry Machinery

The process of outsourcing manufacturing to foundry machinery varies. In some instances, the specifications are communicated to the foundry, and the design is outsourced, while in other cases, the CAD data is passed to the foundry and the manufacturing is outsourced. Sometimes, foundry machinery is contracted to manufacture silicon wafers, while in other cases, it is contracted to manufacture elements and integrated circuits.

Each manufacturer has different requirements for foundries. In actual contract manufacturing, foundries often consider the best manufacturing method to meet the requirements of the contractor.