What Is UV Curable Adhesive?

UV curable adhesives are adhesives that cure by irradiation of ultraviolet light.

They are also called UV (ultraviolet) curable adhesives. Compared to general dry-curing adhesives, they are characterized by their excellent quick curing properties and small volume change during curing. In addition, since it does not require the application of heat, it is suitable for use with plastic materials with low heat resistance.

On the other hand, it is not suitable for use in intricate and complicated structures because it cures only the part irradiated by ultraviolet rays. Also, if many adhesives are used, they may not cure sufficiently.

Uses of UV Curable Adhesives

Advantages of UV curable adhesives include instant curing, high bonding strength, transparency, weather resistance, heat resistance, and chemical resistance. They are also considered environmentally friendly because they do not contain solvents.

However, UV irradiation equipment is required for use. In addition, areas that UV light does not reach will not be cured.

1. Electronic Devices and Components

Bonding printed circuit boards, fixing components, protecting wires, assembling liquid crystal displays, etc.

2. Glass and Optics

Bonding and reinforcing glass, assembling lenses and prisms, connecting optical fibers, etc.

3. Automotive Industry

Manufacturing headlights and taillights, fixing interior components, bonding emblems, etc.

4. Medical and Dental

Dental filling materials and cement, assembly and repair of medical equipment, etc.

5. Plastics and Resins

Bonding and molding of synthetic resins and plastics, repair of molded products, etc.

6. Jewelry and Accessories

Adhesion of metals, glass, and stones, repair of ornaments, etc.

Principle of UV Curable Adhesives

UV curable adhesives contain ingredients such as monomers, oligomers, photoinitiators, and additives. When UV light is irradiated on UV curable adhesives, the photoinitiator absorbs the UV light and generates radicals, cations, or anions, depending on the type of photoinitiator.

Depending on the polymerization species generated by the initiator, radical polymerization, cationic polymerization, or anionic polymerization causes monomers and oligomers with small molecular weights to combine with each other to form polymers with large molecular weights, which is the curing mechanism.

The radical polymerization type has a fast curing speed and is widely used in general. Compared to the cationic and anionic polymerization types, it is easier to synthesize monomers and oligomers, making it possible to change the composition of the resin according to the required performance.

On the other hand, the cationic polymerization type and anionic polymerization type are characterized by small shrinkage during curing, and are effective in cases where the material cannot be shaped by pressurizing or where precision is required.

Types of UV Curable Adhesives

UV curable adhesives can be made with various characteristics depending on the type of monomer that makes up the adhesive. The monomers included in UV curable adhesives are listed below.

Examples of acrylic monomers used in UV curable adhesives include monofunctional acrylates and multifunctional acrylates, such as bifunctional and trifunctional.

1. Monofunctional Acrylate

Compared to bifunctional and trifunctional acrylates, monofunctional acrylates have fewer polymerization reaction sites, which reduces the cross-link density of the resin. This can be expected to reduce the viscosity of the resin and increase its polymerization reactivity.

It is used to adjust the properties of adhesives by mixing with other monomers or oligomers, rather than using alone.

2. Bifunctional and Trifunctional Acrylates

They can create a two-dimensional crosslinked structure, which improves the strength of the adhesive. They can also increase solvent resistance and hardness. These acrylates have many reaction sites and cures in a short time, making them efficient in terms of workability.

However, if too much bifunctional or trifunctional acrylate is added, the overall polymerization rate may be poor because of the large number of reaction sites involved. In addition, the shrinkage of the adhesive during the polymerization reaction becomes larger, which may cause problems, such as poor adhesion to the base material or curvature of the base material.

Other Information on UV Curable Adhesives

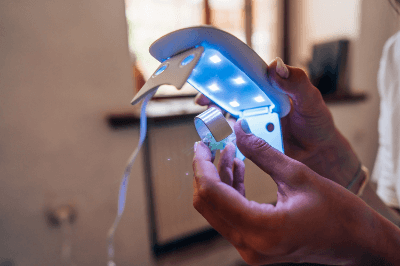

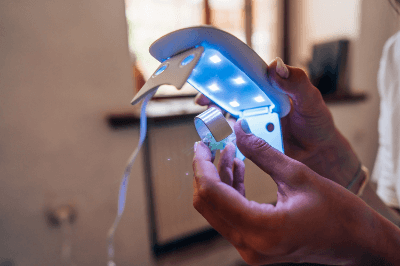

1. How to Use UV Curable Adhesives

As with widely used heat-curing adhesives, apply an appropriate amount to the desired area. Next, using a UV light or other UV irradiation device, irradiate UV light to the area where the adhesive has been applied, and curing will begin immediately.

The curing reaction is completed in a short time, and the adhesive is bonded. As you can see, UV curable adhesives are very easy to use, so anyone can easily use them.

2. Cautions for UV Curable Adhesives

There are two main points to note when using UV curable adhesives: First, the irradiation intensity of the UV light used must be set appropriately. If the intensity is high, the curing reaction of the adhesive proceeds quickly, but if it is excessive, the curing reaction proceeds only on the surface of the adhesive and the interior may not cure sufficiently.

As a result, there is a possibility that the adhesive strength will become small. If the intensity is too small, the amount of radicals generated by irradiation is small and may react with oxygen in the air, resulting in inadequate curing.

Second, it is necessary for the UV light to reach the point where the adhesive is applied. Due to the characteristics of adhesives, most of the areas where they are applied are intricate or between items to be bonded. Therefore, the ultraviolet rays necessary for curing do not reach the adhesive, and curing may be insufficient. It is necessary to devise a way to ensure that the UV light is irradiated firmly to the area where the adhesive is applied.