What Is a Pilot Pin?

A pilot pin is a component used in precise positioning for machining or assembling manufacturing equipment. It ensures accurate alignment and positioning of objects during various industrial processes.

Common applications of pilot pins include:

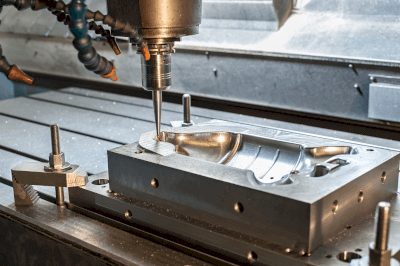

- Mold alignment in processes using molds, such as in injection molding machines.

- Positioning of workpieces in conveyance systems, including the stopping position of workpieces on processing machines.

Pilot pins are usually inserted into holes with high dimensional accuracy, allowing for precise mating of parts.

Uses of Pilot Pins

Pilot pins are essential in modern industrial products, utilized across a wide range of applications, from large-scale products to precision equipment. They are classified into two types: parallel pins, which are used for rough positioning and easy removal, and knock pins, which are used for accurate positioning and repeated application to a workpiece.

Principle of Pilot Pins

Knock pins, also known as hammer pins, are commonly used for centering and positioning equipment. They are typically referred to as dowel pins and are inserted into holes with a positive tolerance, requiring hammering for installation.

Parallel pins, in contrast, have both positive and negative tolerances and are not typically hardened. Due to their material properties, they are suitable only for rough or static positioning. However, their ease of attachment and detachment makes them more user-friendly compared to knock pins.

When selecting pilot pins, it is crucial to consider the intended use, performance requirements, and other factors to choose the appropriate type of pin for the specific application.