What Is Welded Pipe?

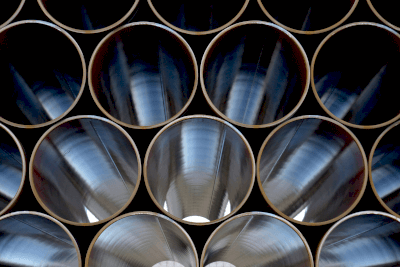

Welded pipes, typically made from steel, are formed by shaping a steel strip into a circular structure and joining the seams using electric resistance welding. These pipes are also known as ERW (Electric Resistance Welded) pipes.

Characterized by their thin walls and continuous manufacturing process, welded pipes can be produced cost-effectively in large quantities. They are available in various diameters, from small (6A) to large (700A). Various materials, including carbon steel, stainless steel, and low-alloy steel, are used for manufacturing welded pipes. However, weld marks may remain on these pipes, requiring additional finishing if appearance is a concern. Welded pipes are extensively used for piping, automotive parts, machinery, and building structures.

Uses of Welded Pipe

Welded pipes offer versatility in terms of material, diameter, thickness, and length. They are employed in various applications, such as:

- Construction: Steel pipe piles, sheet piles, scaffolding, foundation piers, and structural components.

- Transportation: Parts for automobiles, bicycles, and machinery.

- Utilities: Piping for water, sewage, steam, gas, air, and high/low-temperature environments.

- Industrial: Boiler water pipes, flue gas pipes, heaters, and heat exchangers.

- Hydraulic and pneumatic systems: Cylinder tubes for hydraulic and pneumatic cylinders.

Alloy steel pipes, such as stainless steel sanitary tubing, are also used in the dairy, food, medical, and pharmaceutical industries.

Principles of Welded Pipe

Welded pipes are made from coiled steel strips that are uncoiled, leveled, and processed at the edges. The strip is shaped into a circular form and welded using methods like high-frequency resistance welding, high-frequency induction welding, or electric resistance welding. These processes involve heating the joint area to high temperatures and pressing it together to form a seamless bond.

The welded pipe is then cut, cooled, and straightened to achieve the desired specifications.

Types of Welded Pipe

Welded pipes can be categorized into two primary types based on the material:

- Carbon Steel Welded Pipes: Commonly used for structural purposes, these pipes are made from various grades of carbon steel, from low to high carbon content.

- Alloy Steel Welded Pipes: These include stainless steel, chromium/molybdenum steel, and high manganese steel pipes, used for specific applications like sanitary pipes, boilers, and heat exchangers. Stainless steel, known for its corrosion, oxidation, and heat resistance, is often used in high and low-temperature environments. Chromium molybdenum steel is characterized by its heat and pressure resistance, suitable for thermal power plants and oil refineries.

Standards and Differences from Seamless Pipes

Welded pipes conform to various standards, including those for general structural purposes, machine structures, piping, and heat exchangers. The manufacturing method is indicated by the symbol “E” for electric resistance welding. The finishing method is also denoted, with “H” for hot finishing, “C” for cold finishing, and “G” for no finishing.

Compared to seamless pipes, which are made from solid round bars, welded pipes are less expensive but not as strong, especially in terms of internal pressure and torsion resistance. While seamless pipes offer higher dimensional accuracy and smoother surface properties, they tend to be costlier.