What Is Expanded Metal?

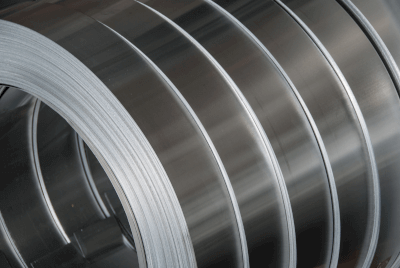

Expanded metal is a versatile material formed through processes like rolling, forging, drawing, extruding, or other means of shaping metal into various forms such as plates, strips, bars, wires, tubes, and profiles. These forms exhibit the inherent physical properties of their metal constituents, generally characterized by hardness, strength, and durability.

Its applications span across architecture, automotive parts, furniture, and interior design. In construction, expanded metal contributes to steel structures, while in the automotive sector, it’s integral to components like engine parts, suspensions, and wheels. Additionally, it finds utility in furniture and interior design contexts.

Uses of Expanded Metal

- Construction: Utilized in building steel structures, steel roofing for malls, and large sports facility frameworks.

- Automobiles: Forms parts of automobile engines, suspension systems, and wheel rims.

- Furniture and Interiors: Used in manufacturing steel chair legs and metal wall clocks.

- Mechanical Parts: Integral to the production of gears, bearings, and various types of springs and wheels.

- Electronic Equipment: Found in PC cases, power supply unit enclosures, and frames for audio equipment.

Principles of Expanded Metal Production

- Rolling: Metal sheets or bars are stretched under pressure, using cold or hot methods, for flexibility and complex shapes.

- Forging: Heating and pressurizing metal to enhance its strength and durability through a uniform structure.

- Drawing: Drawing metal through a die to produce thin parts like wires and pipes.

- Extrusion: Passing metal through a die to extrude it into desired shapes such as tubes or bars.

- Draw Work (Stretching Process): A method suitable for thin sheet materials, drawing metal through a die.

- Hot Drawing: Heating metal before drawing through a die for thin parts production.

Types of Expanded Metal

- Material: Includes steel, aluminum, copper, stainless steel, titanium, nickel alloys, and other alloys.

- Shape: Varieties include plates, bars, wires, tubes, and profiles with distinct cross-sections like H-beams and I-beams.

- Applications: Ranging from construction materials to automotive parts.

- Manufacturing Method: Encompasses rolling, forging, drawing, and other techniques.

Other Information on Expanded Metal

Expanded metal undergoes various surface treatments to enhance its material characteristics, appearance, and durability. These treatments include rustproofing, painting, coating, plating, quenching, and, where necessary, heat treatment to improve fatigue resistance by controlling the metal’s internal microstructure.

- Pickling Treatment: Cleans the metal’s surface by removing oil, grease, and oxides using acid.

- Plating Treatment: Enhances appearance and corrosion resistance through metal plating, including zinc, chromate, nickel, chrome, silver, gold, and tin plating.

- Coating Treatment: Applies coatings to improve color, appearance, and resistance to rust and corrosion. Coatings include epoxy, urethane, acrylic, and fluorine resins.

- Anodizing: Covers the surface of light metals with an oxide film to harden it and improve corrosion resistance, wear resistance, and electrical insulation.

- Passivation Treatment: Improves strength and corrosion resistance by forming a protective oxide film on metals like stainless steel and titanium.

- Heat Treatment: Employs high temperatures to enhance the metal’s structure, hardness, and strength, and reduce brittleness through methods like quenching and tempering.