What Is a Spline?

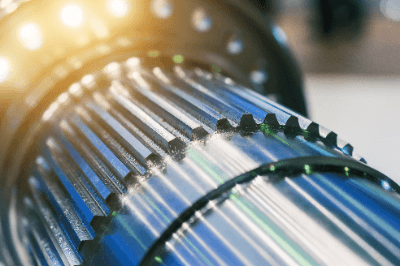

A spline is a mating structure that joins two parts. It consists of a spline shaft with a gear-shaped concave-convex groove on its cylindrical outer diameter. This mates with a sleeve that has a corresponding groove inside its bore. This combination facilitates the transmission of torque.

Splines are known for their excellent alignment characteristics. They are commonly used in mechanical parts that transmit large amounts of torque and can absorb axial displacement during torque transmission. A similar structure, known as serration, has a finer gear shape than splines.

Serrations, compared to splines, are more suitable for thin shafts and walls. They are used to minimize rotational rattling in shaft-sleeve combinations and ensure torque transmission without axial displacement.

Uses of Splines

Splines play a crucial role in the gear-shifting mechanisms and power transmission parts of automobiles and machine tools. In RWD vehicles, they are specifically used in propeller shafts.

In FWD cars, splines facilitate the connection between the transaxle and the drive shaft.

Whether fixed or sliding axially, splined shafts and sleeves often require grease for lubrication. Some designs include a grease inlet for periodic lubrication.

Principle of Splines

Splines transmit torque through tooth flanks that are orthogonal to their circumferential direction. Unlike gears, which transmit torque between parts with different central axes, splines use a shaft and sleeve with the same central axis. This arrangement allows rotary motion in the same direction along the same axis.

Types of Splines

There are three main types of splines, categorized based on the alignment of their central axis in the tooth profile and the structure of the steel balls used for torque transmission.

1. Square Splines

Square splines have parallel tooth flanks and center at the splines’ small diameter. Though difficult to manufacture, they are essential for certain applications.

2. Involute Splines

Involute splines feature tooth flanks formed by involute curves, centering on these flanks. Their shape is widely adopted in industrial products, offering advantages like self-alignment, ease of manufacturing, and high torque transmission capability.

3. Ball Splines

Ball splines are ideal for applications requiring axial sliding. They use steel balls placed in half-moon grooves on the shaft and sleeve, allowing smooth axial sliding while transmitting torque.

Other Information on Splines

Design Considerations for Splines

When designing splines, it’s crucial to match the shapes of the shaft end and sleeve’s mating part to the attached machinery. Design for strength to ensure the spline’s shape withstands the applied torque.

Depending on the operating environment, incorporating a dust seal at the spline shaft insertion point of the sleeve may be necessary. This seal maintains grease integrity and prevents foreign matter entry, reducing wear and noise during torque transmission.