What Is a Metal Fastener?

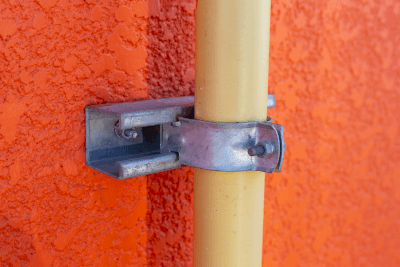

Metal fasteners are versatile components used to secure objects. These are categorized based on their specific applications, such as “rocking metal fasteners” or “wiring metal fasteners.”

The choice of shape and material depends on the object being fixed and the required strength. Options include galvanized stainless steel and brass.

Given their metallic nature, it’s crucial to prevent acid-induced corrosion. Use in non-corrosive environments or opt for acid-resistant materials when necessary.

Uses of Metal Fasteners

In assembling experimental devices, clamps are often utilized to reinforce part connections. For example, metal fasteners can secure an electrical cord to a stand’s support, ensuring it doesn’t interfere with the experimental setup.

They also play a crucial role in anchoring equipment to stands or ceilings, preventing displacement or falls due to vibrations. In cases like mounting analyzers on a plate, L-shaped metal fasteners are effective in securing them against earthquakes.

Principle of Metal Fasteners

Metal fasteners typically feature a body with screw holes. Selection should be based on the intended use, with particular attention to:

- Shape of the Main Body: U-shaped bodies are ideal for securing electrical cords and posts, while L-shaped fasteners are better for vertically aligned parts.

- Screw Strength: Choose removable screws for assemblies that require frequent adjustments. For long-term stability, as in securing analyzers, select high-strength screws.

- Material: Common materials include stainless steel (an iron and chromium alloy), brass (a copper and zinc alloy), and zinc plating. Brass is affordable but less suitable for lab environments due to its low chemical resistance. Zinc plating offers extended durability through zinc‘s sacrificial corrosion protection, though it’s vulnerable to strong acids. Stainless steel, indicated by codes like “SUS304” or “SUS316”, generally provides high chemical resistance, varying by type.