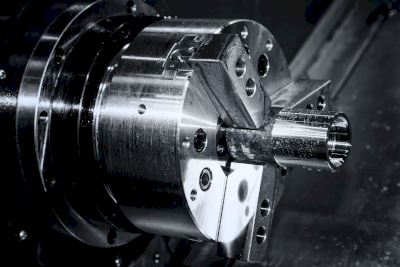

What Is a Scroll Chuck?

A scroll chuck is a device attached to a lathe’s spindle to hold a workpiece. By manually turning the chuck handle, the three jaws, positioned at 120° intervals, move simultaneously to grip the workpiece.

While scroll chucks typically handle round workpieces, a three-jaw scroll chuck can also grip hexagonal workpieces, and a four-jaw chuck can accommodate square workpieces.

The jaws of the chuck can be custom-molded to fit specific workpieces. In this setup, the jaws are usually secured with a fixture such as a jaw lock or chuck mate, and then bored together on the machine.

Uses of Scroll Chucks

Scroll chucks have been commonly used on general-purpose lathes. However, with the advancement of automation and the prevalence of CNC lathes, the demand for hydraulic power chucks and air chucks has increased, leading to a decrease in the use of scroll chucks.

Still, some manufacturing sites continue to use scroll chucks. The advantage of manual chucking is the ability for experienced operators to make fine adjustments, making scroll chucks a practical choice in some production environments.

Principles of Scroll Chucks

Scroll chucks are distinguished by their internal cam mechanism featuring a spiral groove known as a scroll.

In a three-jaw scroll chuck, there are three pawls spaced at equal intervals, each aligned with the grooves in the scroll. The jaw grooves are positioned differently to ensure the jaws are arranged in concentric circles.

Turning the scroll chuck handle causes the scroll to rotate via the bevel gear, moving the three pawls radially. This movement allows the workpiece to be gripped at the center position.

However, due to the scroll chuck’s design, exact centering of the workpiece is not possible. An average eccentricity of about 0.07 mm is typical and must be taken into account.

To achieve minimal eccentricity during processing, it is essential to minimize clamping changes. If grip changes are necessary, such as for back machining, a four-jaw independent chuck can be used.