What Is a Waterproof Connector?

Waterproof connectors are connectors that prevent water from entering the electrical wiring and prevent electrical problems, such as shorts between terminals from occurring, even if the connector is exposed to water.

Waterproof connectors are connectors that prevent water from entering the electrical wiring and prevent electrical problems, such as shorts between terminals from occurring, even if the connector is exposed to water.

Waterproof connectors consist mainly of a connector body and a rubber packing that fill the gap. In order to prevent water from entering the connector, the male and female connectors are mated in a press-fit manner, with no gap between the male and female connectors. This makes the removal of waterproof connectors harder and more difficult than non-waterproof connectors.

Some products have a lever on the connector to improve the reliability of waterproof connectors, and by lowering the lever after mating the male and female connectors, the connector will not come off unless the lever is raised again. Waterproof connectors are used in places where waterproofing and dustproofing are required, such as cars and motorcycles that are used in the rain, as well as ships and machine tools.

Uses of Waterproof Connectors

Waterproof connectors are used in places where a large amount of electrical wiring is required and where water and dust resistance is required. For example, they are used for products that are stored in the rain or used in the rain, such as cars and motorcycles.

Other than that, it is also useful for products such as machine tools that use a large amount of cutting oil and are constantly exposed to a humid environment while producing a large amount of chips and ships that may be exposed to seawater. They are also often used in machines used in clean rooms, such as machines for semiconductors.

Waterproof connectors have different standards for waterproof performance, and since different products have different standards for waterproofness. It is necessary to check them carefully according to the application for which they are used.

Principle of Waterproof Connectors

Waterproof connectors generally consist of a connector body that mates with the mating device and a rubber packing that fills the gap to prevent water from entering. The rubber packing is attached like a plug to fill the hole not only on the mating surface of the connector but also on the connection surface with each wire that enters the connector.

In many cases, when wires and terminals are crimped, the rubber plugs are rolled in and crimped together. Both the male and female sides contain similar packing, and when the connectors are mated, the packing eliminates the gap between each other to maintain airtightness. For this reason, waterproof connectors are more difficult to attach and detach. firmly when mated than non-waterproof connectors.

Some products have a lever attached to the connector, which must be physically raised or lowered to prevent it from coming off due to vibration after mating.

Types of Waterproof Connectors

There are many types of waterproof connectors, depending on the connection method.

1. Permanent Engagement Type

Permanently engaged waterproof connectors can be purchased at general home improvement stores. They are mainly used for devices such as motorcycles and cars. The always engaged waterproof connector has a rubber packing inside to provide high waterproof performance.

Although it is possible to install the connector as if you were a carpenter, since the male and female connectors are mated without a gap for waterproofing, it requires a little trick to disengage the connector once it is engaged. In the worst case, if the connector is removed in the wrong way, the connector itself will break, making it impossible to demonstrate its waterproof performance, so care must be taken.

Also, since it is made of plastic, it is slightly less weather resistant.

2. Plug Type

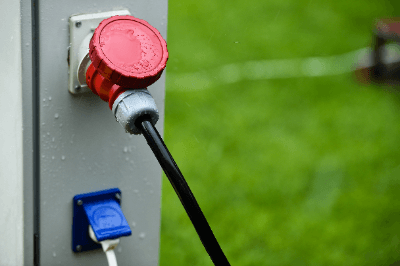

Metal plug-type waterproof connectors are often used for industrial applications. These are very easy to install and remove because the male and female plugs mate with screws.

Since they are made of metal, they are strong and reliable, and can be used outdoors without problems. Panel-mounted type is often used for penetrating through machines and control panels.

They are pre-installed on the back of the machine, etc., and can be easily connected by tightening screws and mating. These waterproof connectors are also called “cable grants.”

Other Information on Waterproof Connectors

Importance of Waterproof Connectors

When connecting numerous wires one by one in an area where water and dust resistance is required, it is very time consuming. In addition, if all the wires are in an area that may be disassembled or repaired in the future due to damage or short-circuit caused by exposure to water. It will be impossible to disassemble or repair the entire unit without disassembling the entire unit.

Therefore, it is common to use a component called a “connector” to divide the wire into appropriate sections and connect them as a single wire by mating the connectors together. Waterproof connectors are useful in outdoor locations where water or dust may enter.