What Is a Gas Flowmeter?

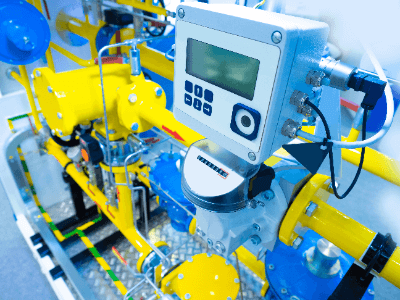

A gas flowmeter is an instrument designed to measure the quantity of gas flowing through a pipe or other equipment.

There exists a wide variety of gas flowmeters, each employing different principles of measurement, structures, and applications. These flowmeters are used to measure gas flow rates across various industries.

Gas flowmeters come in different types, including electronic flowmeters with digital displays, mechanical flowmeters with analog displays, and sensors that provide electrical signals without a visual display. Recent advancements have also introduced non-contact types of flowmeters that are suitable for high-temperature and corrosive gas measurements, as they do not make direct contact with the fluid.

Applications of Gas Flowmeters

Gas flowmeters find extensive use in various industrial sectors for measuring the rate of gas flow within pipes and specific structures. While their presence in everyday life is limited, residential gas meters are installed in households to measure gas consumption. In industrial settings, these flowmeters are essential for controlling gaseous fluid processes and managing gas distribution volume.

It’s important to note that gas flowmeters primarily measure the volume of gas in circulation, and there are also flow controllers available with additional flow control functionalities.

Principles of Gas Flowmeters

Gas flowmeters operate on diverse measurement principles, each suited for specific gas properties, temperature ranges, measurement ranges, and additional specifications. They can be broadly categorized based on their measurement principles:

1. Ultrasonic Type

The ultrasonic method is a modern and widely used measurement technique. It enables non-contact measurement, making it suitable for high-temperature or corrosive gases. Ultrasonic flowmeters employ sensors mounted externally to the piping and come in two main types: Doppler and transit time, which measure flow based on differences in wave propagation.

2. Coriolis Type

The Coriolis method, based on the Coriolis principle, excels at measuring mass flow rates with high accuracy. It can also calculate temperature, density, concentration, and volumetric flow rates based on the measurement results.

3. Thermal Type

The thermal method determines mass flow rates by placing a measuring unit with two heaters inside the gas and measuring the output difference resulting from heater cooling by the gas flow. This type allows for direct mass flow measurements. However, it requires contact with the fluid and may not be suitable for all gases due to potential impurity-related measurement deviations.

4. Differential Pressure Type

The differential pressure method is based on Bernoulli’s theorem and is a cost-effective measurement approach. It typically requires an orifice, which can lead to substantial pressure drops. Accuracy may be compromised if the gas flow velocity distribution in the channel is uneven.