What Is a Chain Coupling?

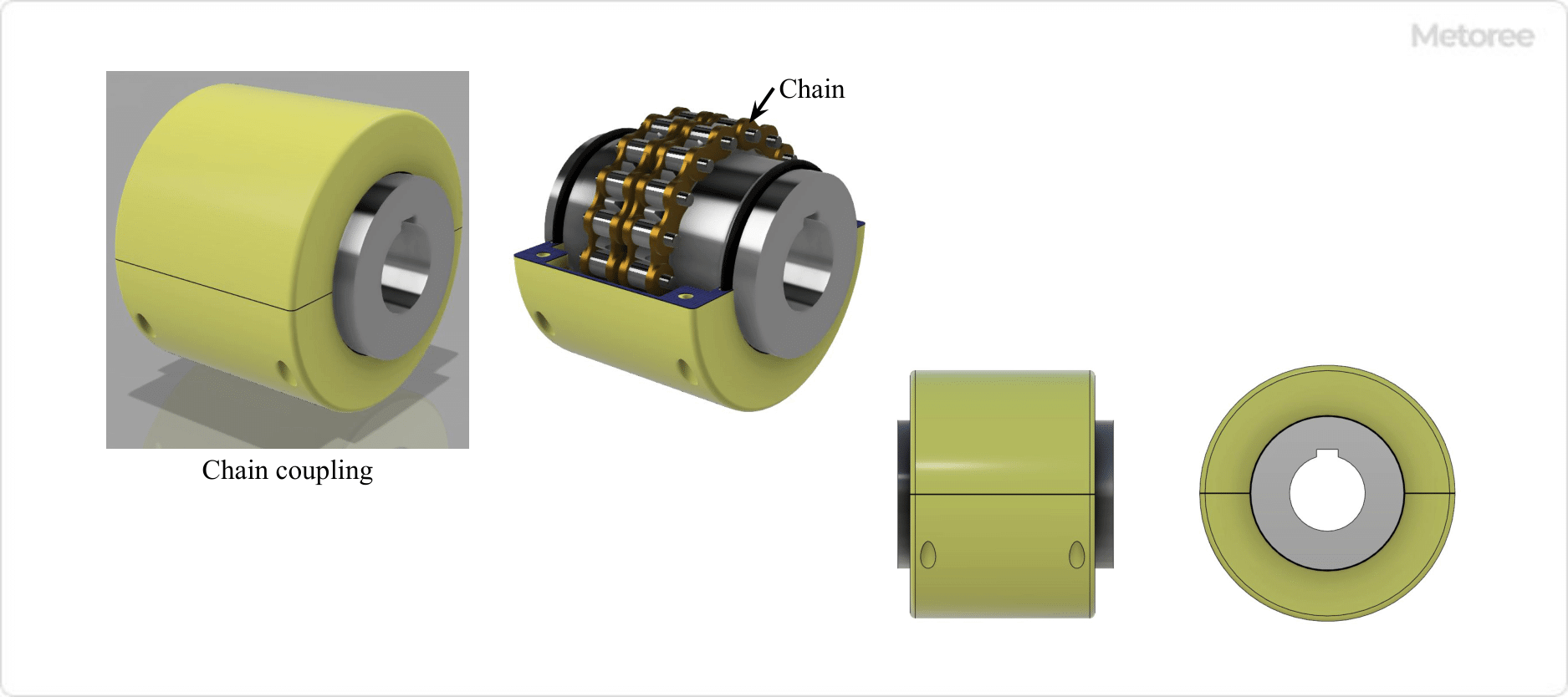

Figure 1. Appearance of chain coupling

Chain couplings are shaft couplings that use sprockets and chains to connect two shafts, and are a type of flexible shaft coupling (coupling).

A shaft coupling is a mechanical element that joins two shafts and is responsible for transmitting the power and rotation of the drive shaft to the driven shaft. A shaft coupling is also called a joint or coupling.

Deflection-type shaft couplings can absorb misalignment between two shafts and mitigate shaft mounting errors.

Uses of Chain Couplings

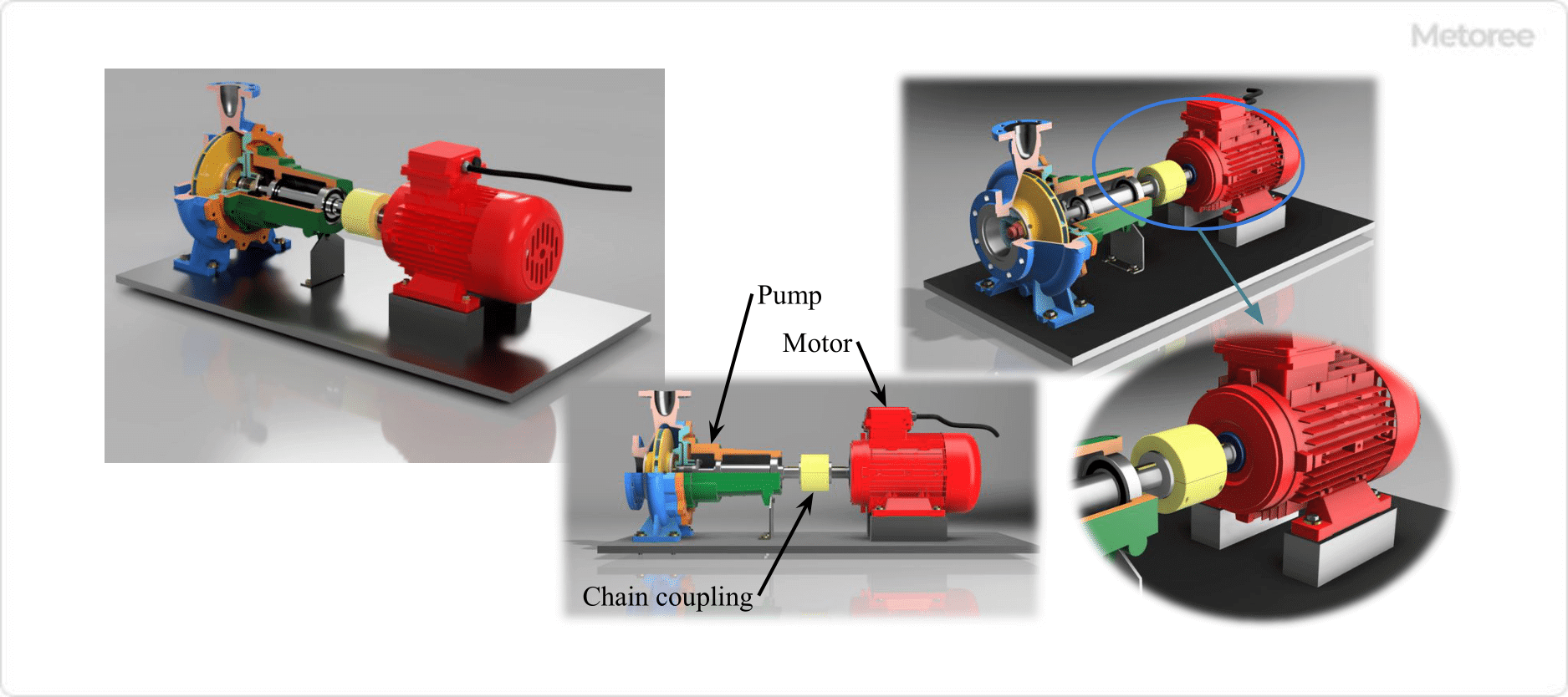

Figure 2. Example of chain coupling use

Chain couplings are shaft couplings used to connect general-purpose general industrial motors to equipment and devices. For example, they are used as shaft couplings between electric motors and pumps in production plant equipment.

The power of the electric motor drives the pump and cools the equipment as cooling water circulates through the equipment. Chain couplings are used especially for general purpose applications.

They feature a wide range of application, with shaft outer diameters from φ10 to φ700 mm and torque ranges from 100 to 700,000 N-m (figures are examples only). In addition, since the connection between the shafts can be disconnected without disassembling or moving the machine, construction work is easier in case of sudden breakdowns or maintenance.

Principle of Chain Couplings

Generally speaking, shaft couplings require a torque transmitting force and a certain misalignment tolerance. If the centering between machine shafts to be connected by a shaft coupling cannot be accurately installed, the machine may be damaged by vibration generated by the misalignment.

In such cases, deflection shaft couplings are used to absorb the misalignment between machine shafts and to prevent the load from being placed on the motor and other machines. Chain couplings are used as one of deflection type shaft couplings and have high transmission capacity and simple structure among deflection type shaft couplings.

Centering is easy, and the play between the chain and sprocket protects the machine from excessive load. In addition, the roller chain and sprocket teeth are meshed, and the torque applied is distributed to multiple chain roller and sprocket teeth, resulting in excellent durability.

Structure of Chain Coupling

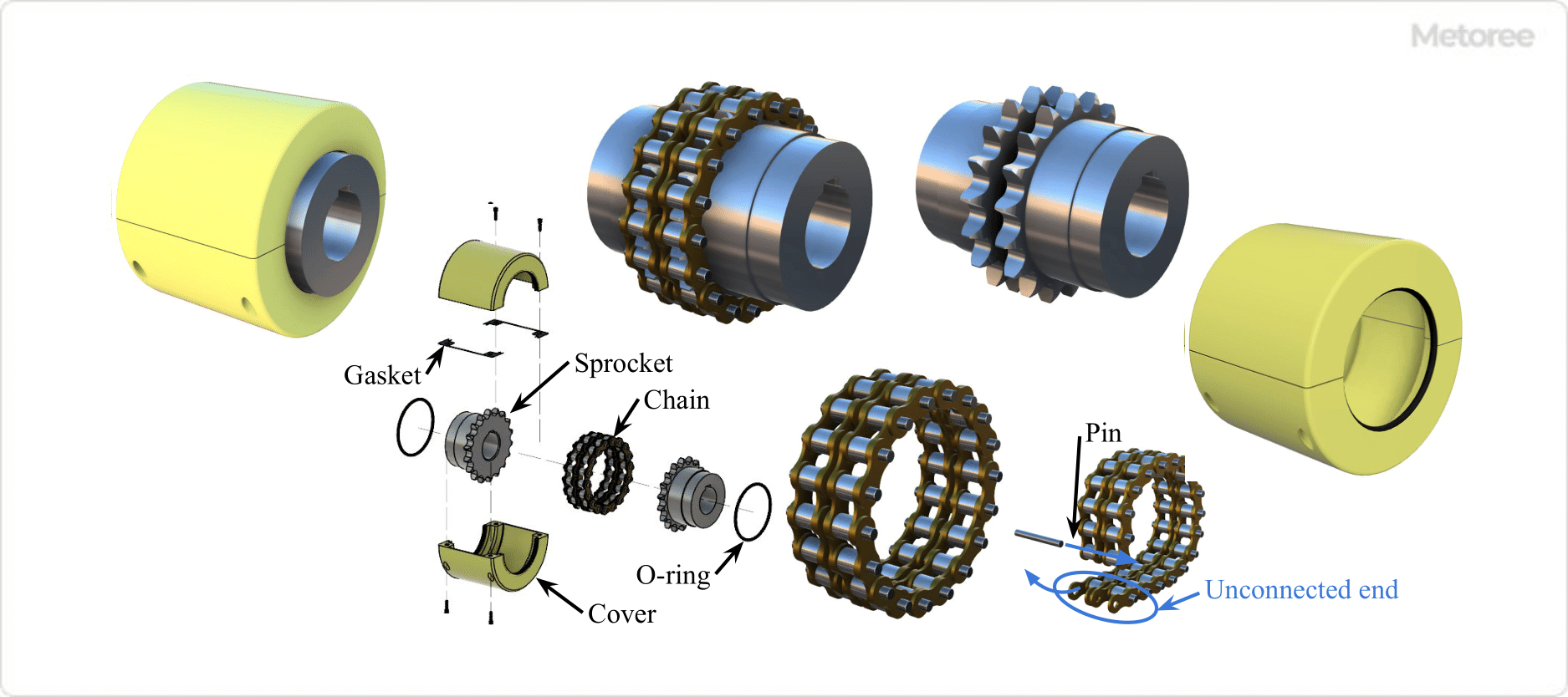

Figure 3. Structure of chain coupling

A chain coupling consists of two sprockets, two rows of roller chains, and a cover that protects the entire coupling. Compared to other shaft couplings, chain couplings have a simpler structure and fewer parts.

For installation on a machine, two rows of roller chains are wound around two sprockets mounted on two shafts, and pins are inserted into the unlinked ends of the chains to connect them. For disassembly, the procedure is the reverse.

A special cover is installed to improve safety and durability without splashing grease on the chain section. 2-divided covers are assembled with bolts between gaskets, and O-rings are installed on both ends to prevent grease leakage. The case must be installed when the coupling is used in high-speed rotation or in dusty or corrosive atmospheres.

Other Information on Chain Couplings

1. Advantages and Disadvantages of Chain Couplings

Chain Couplings have practical advantages, but they also have disadvantages.

Advantages

- Relatively low cost

- High torque transmission capability

- Large tolerance for misalignment

- Easy coupling and disassembly

Disadvantages

- Large backlash

- Grease lubrication required

- Chain and sprocket wear

2. Standards for Chain Couplings

There is no JIS standard for Chain Couplings, but the synonymous Roller Chain Shaft Couplings are specified in the following standard.

- JIS B1456 Roller Chain Shaft Couplings