What Is an Arc Welding Robot?

Arc welding robots are robots that perform arc welding in place of humans.

Arc welding robots are robots that perform arc welding in place of humans.

Compared to other welding robots, arc welding robots are somewhat smaller. Arc welding emits intense light and powerful ultraviolet rays from the arc discharge, so the welding point becomes very hot. Therefore, there is a high risk of burns, even when protected by goggles and work clothes.

Inhalation of fumes from metal vapors is also harmful and is one of the tasks for which robots are in high demand as an alternative. Robots have the advantage of being able to perform welding at high speeds and with stable quality, which also contributes to cost reduction.

Uses of Arc Welding Robots

Arc welding is used to connect metals such as steel to steel, aluminum, and titanium. It is a welding method applicable to almost all metal structures.

The following are examples of products for which arc welding robots are used:

- Steel frames and construction machinery

- Land transportation machinery such as automobiles and railcars

- Large air transportation machinery such as aircraft

- Large marine transportation machinery such as ships

Arc welding robots are used in manufacturing plants for the above products. In recent years, the rationalization of welding has been progressing, and the number of cases in which arc welding robots have been introduced is on the rise. Arc welding robots can also be used for TIG welding and mag welding, which are types of arc welding.

Principle of Arc Welding Robots

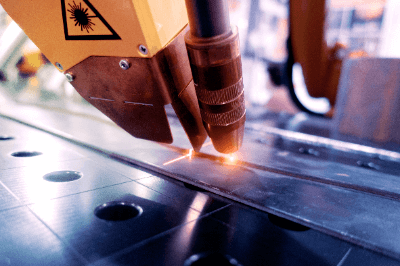

Arc welding is a welding method that uses electrical discharges into the air. An electric current is passed through the welding rod, which serves as the electrode, and when it comes into contact with the metal to be joined and is slowly pulled apart, an arc discharge occurs. The arc is so hot, reaching temperatures of up to 20,000°C, that the metal is quickly melted and joined.

The robot has six to seven vertically mounted articulated axes for precise motion. Each axis has a specific angle and speed at which it can move, and a qualified operator teaches the robot the welding conditions. The conditions and positioning at this time are important and are sometimes determined while performing actual welding.

The part that actually performs the welding is called the welding torch, which is fixed to the tip of the robot. The torch and contact tip must be selected according to the object to be welded.

Structure of Arc Welding Robots

The structure of an arc welding robot consists of a manipulator, a controller, and a programming pendant.

1. Manipulator

The manipulator consists of a base, motor and end-effector. The welding torch attached to the end-effector can be replaced to accommodate various welding conditions. It also has a multi-axis articulated structure with servo motors.

2. Controller

The controller consists of data storage and communication equipment with the manipulator. Welding conditions and other data are stored in the controller.

3. Programming Pendant

The programming pendant is an interface through which a person teaches welding conditions to the robot. Data describing the manipulator’s operating procedures can be created, changed, or modified. Control parameter changes and teaching are also performed by the programming pendant.

How to Select an Arc Welding Robot

Arc welding robots must be selected according to the welding material, stroke, and installation method. Welding materials include steel and aluminum. Select a robot that corresponds to the material to be welded.

The stroke is the distance the robot can extend its arm. The longer the stroke, the farther the robot can work, but the more expensive it is. When welding large parts, multiple robots may be installed.

Installation methods include wall-hanging and ceiling-suspension, depending on the conditions in which the robot is to be installed. Select an installation method suitable for the location where the robot is to be installed.

Other Information on Arc Welding Robots

Arc Welding Robot Market

The global arc welding robot market is expected to reach US$11.7 billion by 2026. In addition, the automotive industry is expected to remain strong and demand will continue to grow beyond 2024. The prevalence of automation, especially in developed countries, and labor shortage issues are also factors driving demand.

Arc welding robots are generally sold at prices starting at around several million yen. The amount varies depending on the materials to be welded and the conditions of use.