What Is an Air Impact Wrench?

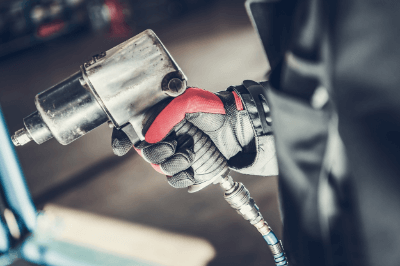

An air impact wrench is a tool driven by compressed air that is used to fasten or loosen bolts and nuts.

An air impact wrench is a tool driven by compressed air that is used to fasten or loosen bolts and nuts.

Since air impact wrenches are powered by compressed air supplied from an external source, they are capable of delivering more power than electric impact wrenches of the same size.

Air impact wrenches can be used to fasten screws and nuts quickly with constant force. It is possible to improve work efficiency and assembly quality uniformity.

Uses of Air Impact Wrenches

Air impact wrenches are used to fasten screws and nuts. Especially in assembly plants, such as automobile assembly lines, production capacity is directly related to how quickly assembly can be completed, so air impact wrenches, which are compact, easy to handle, and can complete fastening work instantly, are in high demand.

In these factories, compressed air is supplied throughout the factory from compressors as a utility for various production facilities, so air impact wrenches can be used simply by connecting a port without the need for a new power source.

Principle of Air Impact Wrenches

An air impact wrench consists of three parts: an air motor that converts compressed air into rotational force, a hammer connected to the air motor, and an anvil that is the output rotating part. A tool called a socket is attached to the anvil according to the shape and size of the screw to be fastened.

When the input port is connected to compressed air and the switch is held, the compressed air causes the air motor and hammer to rotate vigorously. The hammer collides with the projection on the anvil after a certain amount of rotation, but the hammer can continue to rotate at a higher speed than the anvil after the collision.

As the hammer repeatedly collides with the anvil, this impact force tightens screws and nuts.

How to Choose an Air Impact Wrench

There are four points to consider when choosing an air impact wrench

Body shape

Maximum torque or fastening capacity

Socket insertion angle (square drive)

Air consumption or working air pressure

Since the maximum torque, maximum fastening capacity, and air consumption of air impact wrenches vary depending on the model, the appropriate model should be selected according to the diameter of the screw to be used and the maximum flow rate of the compressed air to be supplied.

1. Shape of the Main Unit

Pistol Type

The most common type is the pistol type. With an easy-to-grip grip similar to that of an electric drill, it can be used for a wide range of tasks. A wide variety is available, so you can choose the model that best suits your needs.

D-Handle Type

The D-handle type is often used for maintenance of large vehicles and machinery. It has a D-shaped grip and also has grips on the sides. Since both hands can grip firmly, stable work is possible even at high torques.

Straight Type

The straight type is often used in assembly processes in the manufacturing industry. It is characterized by the ability to change the way it is held freely, either vertically or horizontally, depending on the object being worked on.

Angle (Corner) Type

The angle (corner) type can handle screws in tight spaces or deep locations. They are often used for car and motorcycle maintenance, as well as for replacing nails on farm equipment.

2. Maximum Torque or Maximum Fastening Capacity

Air impact wrenches range in performance from small to large. It is necessary to select a product that is compatible with the torque and screw size required for the work to be performed. It should not be too small or too large.

3. Socket Insertion Angle (Square Drive)

There are five sizes of socket insert angles (square drive) for the main body: 9.5sq, 12.7sq, 19.0sq, 25.4sq, and 38.0sq. Each of these sizes has a different range of compatible screws, so care must be taken when selecting the right one.

4. Air Consumption

An air impact wrench will not perform properly without the proper supply of compressed air. It is necessary to check that the compressor’s capacity matches the product’s air consumption and the air pressure used.