What Is an Antistatic Gun?

An antistatic gun is a machine that neutralizes the static charge of an object.

It neutralizes the static charge of an object by ionizing the air and discharging it along with the air toward the object. It is also called a static eliminator gun because its role is similar to that of an ionizer gun type.

Since high-pressure air is released onto the object, it is possible to remove dust attached to the object as well. They are used in painting and manufacturing to remove dust caused by static electricity.

Uses of Antistatic Guns

When an antistatic gun is aimed at an object to be painted, it can remove not only static electricity but also dust and dirt, thereby reducing defects. A large number of objects require painting, including automobiles, furniture, musical instruments, gas stoves, and plastics, for which antistatic guns are used for pre-treatment of the surface to be painted. Depending on the application, antistatic guns with high air pressure and especially high dust removal capability are preferred.

They are also used to prevent static electricity damage in the manufacture of electronic components, printed films, semiconductors, liquid crystals, and magnetic heads, as well as in the assembly and repair of various measuring instruments.

Principle of the Antistatic Guns

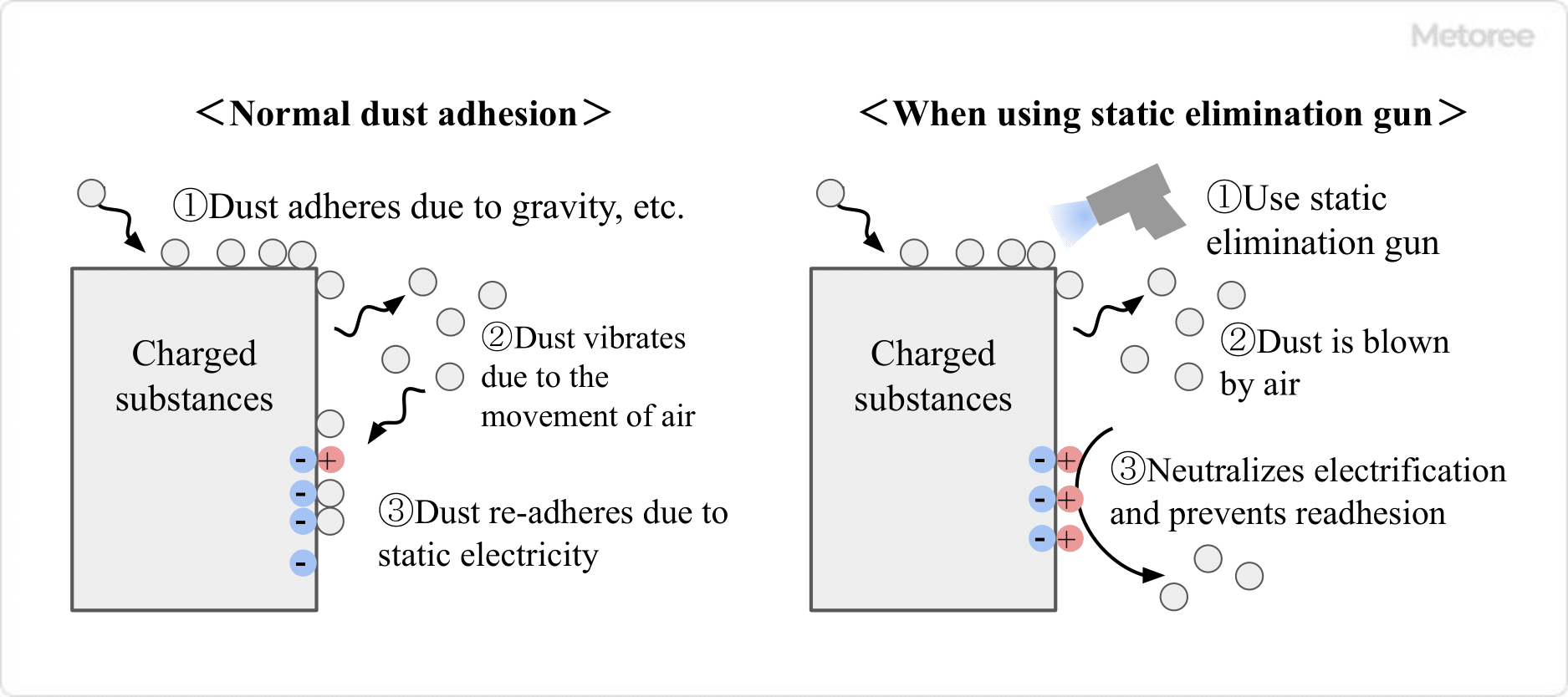

An antistatic gun consists of two main functions: to neutralize static charge by ionizing air, and to remove dust adhering to the surface of the object by blowing air simultaneously.

1. Neutralizing Function

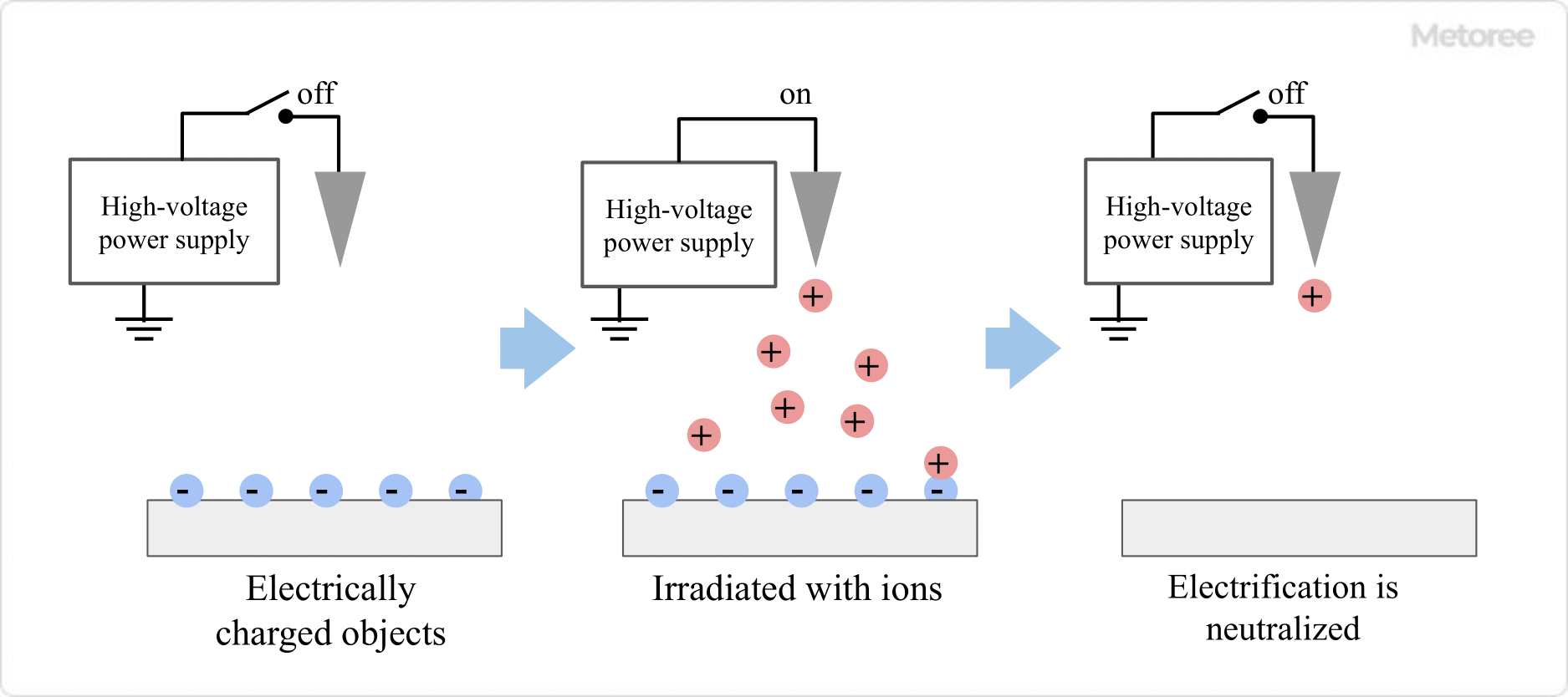

The surface of an object can become charged or unevenly charged with an excessive amount of + or – charges due to various reasons. Therefore, an antistatic gun is used to neutralize the charge by irradiating the surface with + and – ions.

Most antistatic guns use a method called the corona discharge type. Corona discharge is a weak electrical discharge that occurs at the tip of a metal needle when a high voltage is applied to it. This discharge ionizes some of the air near the needle, and the charged object is neutralized when ions with opposite positive and negative charges come into contact with it.

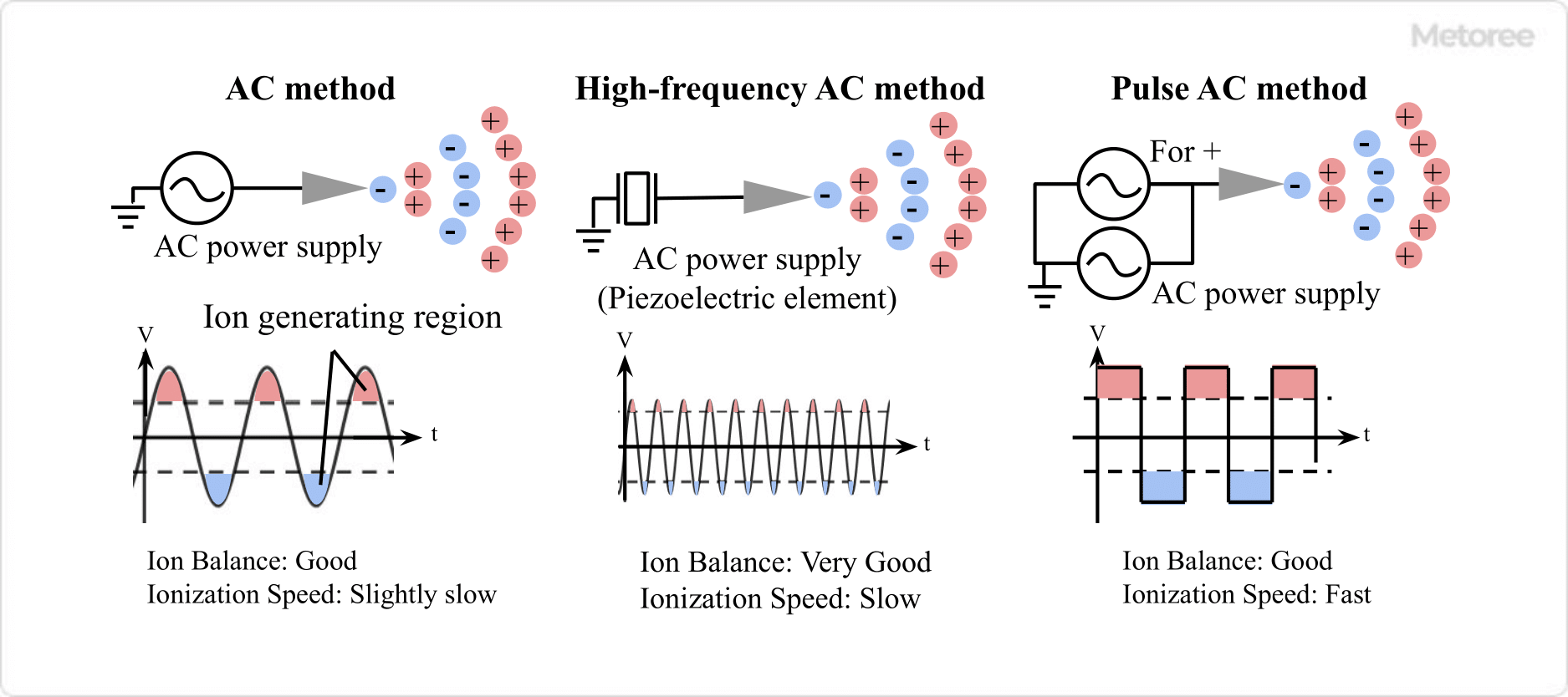

The amount and cycle of ions generated by a corona discharge type antistatic gun vary depending on the voltage applied. The type of voltage applied can be DC (direct current), AC (alternating current), pulsed DC, pulsed AC, high-frequency AC, or SSDC. Since the performance of static elimination, such as the range of ionization, speed, and ion balance, varies, it is necessary to select a voltage type that is appropriate for the application.

The method using AC, which is commonly used for antistatic guns, produces + and – ions periodically. Instead of having a good ion balance, a low voltage slows down the speed of static elimination. Also, since both positive and negative ions are emitted from the same electrode needle, charge recombination tends to occur as the distance from the electrode needle increases, resulting in a decrease in static elimination capability.

Tungsten, silicon, SUS, and other materials are used for electrode needles. The electrode and its surrounding area become dirty during use and must be cleaned periodically. In addition, after a long period of use, metal atoms are said to pop out from the tip of the discharge electrode, and the shape of the electrode changes as if the electrode has been worn away, so the electrode needles need to be replaced periodically (one to two years).

This phenomenon must be avoided in the semiconductor industry, for example, where air pollution is a problem. It is necessary to take countermeasures such as attaching a thin quartz cover or using electrode needles made of silicon.

2. Function to Remove Surface Dust

Dust adhering to the surface of an object may be electrically charged. Therefore, air is used to remove foreign matter adhering to the object’s surface, and ions are simultaneously irradiated to remove the static charge and prevent reattachment.

However, since winded static eliminators blow foreign matter or roll up dust, which can cause foreign matter defects, non-wind-type static eliminators have become mainstream in recent years.

The static-eliminating effect of antistatic guns varies greatly depending on the installation distance, angle, and air volume/pressure.

Other Information on Antistatic Guns

1. High-Power Antistatic Guns

A powerful antistatic gun with not only high static-eliminating capability but also high impact force is required to remove static from objects with high static charge.

The high-powered antistatic gun is equipped with a large-flow solenoid valve that minimizes pressure loss, and its internal structure has been optimized to achieve highly efficient air discharge. The nozzle shape is also ingenious, such as the Laval nozzle, which features a contraction and expansion shape with fine nipples. The housing of the high-power antistatic gun is designed to be even sturdier than a typical antistatic gun to withstand the high-pressure air emitted from the tip of the gun.

The initial velocity of the air at the nozzle tip exceeds the speed of sound. This power is effective even at a distance and can spray compressed air with a maximum wind speed of 50 m/s (at 0.7 MPa) at an object approximately 30 cm away, which is close to actual working conditions.

2. The Dust Removal Function of the Antistatic Gun Is Indispensable for Reliable Static Elimination.

Appropriate dust removal is an essential process for the effective removal of static electricity from objects. Even if the static is removed, the pre-treatment process is incomplete if dust remains on the object.

Typical dust elimination functions that allow the antistatic gun to fully utilize its static elimination capabilities are the pulse air function and the dust check light.

Pulse Air Function

By controlling the movement of the solenoid valve, intermittent release of powerful air is possible. Pulsed air injections ensure that vibrating air is poured evenly and omni-directionally around the object, providing more reliable static electricity removal and powerful dust removal capability. The efficiency of the pulsed air is approximately twice that of continuous injection, offering the labor-saving advantage of achieving the same effect with half the output.

Dust Check Light

Before and after using the antistatic gun, it is important to check for dust, dirt, and other foreign matter attached to the object. An antistatic gun equipped with a surface-emitting LED on the nozzle surface is useful as a highly luminous and even working illumination. This makes it easy to see minute particles that would be missed without the light, contributing to a reduction in defect rates and improved work efficiency.