What Is a Skin Pass Rolling?

A skin pass rolling is one of the processing methods used to process metal materials such as steel sheets.

The purpose is to correct the distortion caused by cold rolling and to smooth the surface of the sheet material to make the surface shiny. Since skin pass rollings may reduce the strength of the sheet, heat treatment may be applied after skin passings to reinforce the strength of the sheet. Skin pass rollings are widely used in the processing of steel plates and other metal materials.

Uses of Skin Pass Rollings

1. Building and Construction

Exterior wall and roofing materials, treads and frame parts for elevators and escalators, and steel structural parts for water supply facilities and river bridges are examples.

2. Automobiles and Transportation Equipment

Automobile exterior panels and frame parts, railroad car exterior panels and frame parts, ship exterior panels and structural parts, etc.

3. Home Appliances and Electronics

Housings and frame parts for home appliances, housings, and frame parts for medical equipment, housings and frame parts for vending machines and ATMs, housings and frame parts for machine tools and measuring instruments, etc.

4. Others

Enclosures and frame parts for lighting fixtures and ceiling fans, and frame parts for golf clubs and tennis rackets are examples.

Properties of Skin Pass Rollings

Skin pass rolling is a light rolling process to smooth the surface of a sheet material, which corrects the distortion of the material and evens out the unevenness of the surface, resulting in even light reflection and luster. Flatness and surface hardness can also be improved.

Skin pass rollings are used as a final finish before more precise processing because they are simple, light rolling or drawing, and do not cause significant deformation of the material after processing.

Types of Skin Pass Rollings

There are three main types of skin pass rollings. The names may differ.

1. Skin Pass Rollings for Cut Plates

Skin rollings are used to adjust the surface condition and correct rolling distortion. The material is processed while light pressure is applied to correct the distortion of the material. The pressure is adjusted according to the strength and hardness of the sheet.

Skin pass rollings for cut sheets are less productive and time-consuming because the sheets are processed one at a time, but it is highly flexible because the sheets to be processed are small and can be formed into a variety of shapes. It is also often used as a final finish before precision machining, since the surface of the plate after machining is smooth and flat.

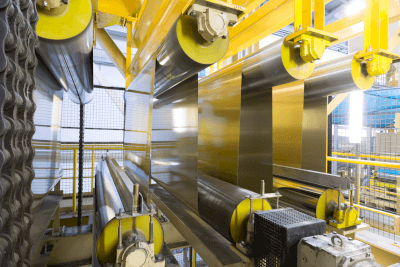

2. Continuous Skin Pass Rollings

Continuous skin pass rolling is one method to continuously process metal materials. A large amount of sheet metal in coil form can be processed at once in a short time, and as the coiled sheet material passes through the skinpass mill, the surface condition of the sheet material is adjusted and distortions are corrected.

Continuous skin pass rollings are a processing method suitable for high-volume production, and their high productivity reduces processing costs. The high processing speed allows for the processing of a large number of sheets in a short time. The processing force can be adjusted according to the thickness of the sheet material, making it possible to process a wide variety of metal materials.

3. Tension Leveling

Tension leveling is a type of skin pass rolling, which is a process of removing surface irregularities by applying tension to the steel sheet and utilizing the reaction of the tension to make the surface flat.

Tension levelers are processing machines that correct rolling distortion and remove warpage by repeatedly bending coiled plates. Tension levelers use the tension (tensile force) inside the coil to bend the sheet material and process it in a bent state.

It is more precise than skinpass mills and can effectively remove rolling distortion. In addition, the repeated bending of the plate material allows the surface irregularities to be evened out, which is a characteristic feature of this process. It is also effective in improving the hardness of plates and is one of the indispensable processing machines for manufacturing high-quality plates.

There are two types of tension levelers: roller levelers with rolls at the front and rear, and top and bottom levelers with rolls at the top and bottom. The former corrects rolling distortion while moving the plate back and forth, while the latter corrects rolling distortion while moving the plate up and down. It is important to select the appropriate tension leveler according to the shape of the sheet material to be used and the purpose of processing.

Other Information on Skin Pass Rollings

Skin Pass Rollings for Plastics

Skin pass rollings are a processing technique mainly used for processing metal materials but are also sometimes used for processing plastic materials. In the case of plastic materials, Skin pass rollings on transparent plastic materials, such as polycarbonate and acrylic resins, can be used to even out surface irregularities and produce a beautiful finish.

Skin pass rollings make the surface of transparent plastic materials uniform and beautifully finished. Small scratches and flaws on the surface of the plastic material can also be polished away in the process.