What Is an Offset Screwdriver?

An offset screwdriver is a crank-shaped tool, highly effective for turning screws that are too long to be maneuvered straight with a regular screwdriver or in locations with restricted clearances.

There is no grip section, and the crank-shaped bent shaft is turned directly. For this reason, some products have an offset of only about 30mm from the shaft.

The shape is different from that of a screwdriver for cap bolts or Torx bolts. It also has a longer reach than the stubby screwdriver, which is as short as a fingertip and is excellent for reaching the cutting edge even in intricate structures.

A similar tool is the flexible screwdriver. While this tool performs well in non-straight spaces, its drawback lies in its lower tightening force. If a straight screwdriver is not possible, an offset screwdriver is applicable.

Uses of Offset Screwdrivers

This tool is suited for work in confined spaces that are intricate and do not allow for a straight space. It is also ideal for situations where a short screwdriver alone is insufficient, and additional force is required to turn a screw.

An example of their application includes the “replacement of parts” within equipment, “maintenance” inside machines, and “vehicle maintenance.” In particular, machines with intricate structures require offset screwdrivers of various shapes.

For in-plant work, construction sites, or railroad track repair, they can be applied to ripped-groove steel, commonly known as C-channel.

How to Choose an Offset Screwdriver

Overall shape

It is preferable to use various types, depending on the location, to leverage the advantages that regular screwdrivers may not reach.

- S-shape

This is a very common offset screwdriver form. It is double-headed, and either type can play the role of a screwdriver. Depending on the type, both have the same shape or a combination of positive and negative. These are the standard offset screwdrivers. - Z-shape

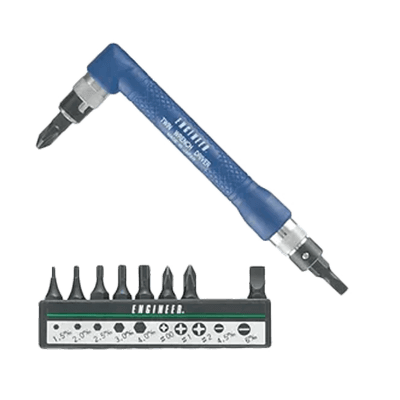

The S-shape is further angled to accommodate tight spaces. - 90-degree (L-shaped)

The 90-degree offset screwdrivers are preferred when the opposite side of a Z- or S-shaped screwdriver interferes with other objects. Another feature of this type is that it is relatively inexpensive. - Low-Profile (Flat Type)

Even the screwed-in part at the tip is 1cm short (thin). The grip portion is almost plate-like and can be inserted as long as there is a gap. The size of the tool is minimized for tightening and unscrewing inside intricate and narrow machines and for avoiding unnecessary contact of the tool with precision parts. - Tip Shape

A plus type and a minus type are available. Select one according to the target screw shape. Thin-type offset screwdrivers are also available in various hexagonal and square shapes. Although relatively expensive, they are versatile, as they can be used for a wide range of applications. - Tip Magnet

Like regular screwdrivers, some screwdrivers can adhere a magnetic screw to the tip. This is useful in places where it is difficult to reach and hold the screw. - Ratchet Type

Ratchet-type screwdrivers are efficient when the space for work is narrow, and it is difficult to raise the screwdriver after one turn or to improve workability.