What Is a Carbide Rotary Bar?

A carbide rotary bar, also known as a master cemented carbide bar, is a type of cutting tool used for various machining operations.

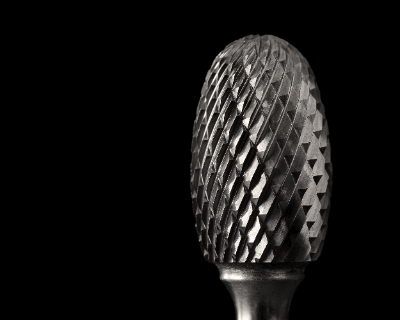

These bars, commonly referred to as carbide rotary bars, are affixed to rotary tools such as air grinders. They are made of tungsten carbide (WC) and cobalt (Co), which are artificial cemented carbides composed of hard metal carbides and ferrous metals. Tungsten carbide bars are capable of cutting extremely hard materials like metals with high precision.

Tungsten carbide bars are categorized into spiral-cut, master-cut, and aluminum-cut based on the blade configuration. Master-cemented carbide bars specifically feature a master-cut blade shape.

Uses of Carbide Rotary Bars

Carbide rotary bars are utilized for finishing operations such as shaping and deburring of hard materials like stainless steel and heat-resistant alloys. Master cemented carbide bars, with their right-rotating and left-rotating helical cutting edges, offer reduced cutting resistance and minimized vibration during operation.

They are suitable for machining a wide range of materials including carbon steel, alloy steel, heat-resistant steel, and stainless steel. However, they may encounter issues with clogging when used on materials with lower melting points like aluminum and resin.

Types of Carbide Rotary Bars

The blades of master carbide bars come in various cutting types: master cut, double cut, and cross-cut. While a single-cut (or spiral-cut) blade features cutting in only one direction, a master cut has an additional blade in the opposite direction. The master cut is preferred for manual operation as it produces powdered chips, whereas single-cut blades generate needle-like chips.

1. Cross Cut

This is the most common blade shape, offering lower cutting resistance than spiral cut and producing powdery chips to minimize chatter.

2. Spiral Cut

A single-cut twisted blade with high cutting efficiency. It efficiently processes materials in a short time and produces needle-like chips. Although it has slightly higher cutting resistance than cross-cutting, it provides a better surface finish.

3. Aluminum Cut

Designed for improved chip evacuation with a wider chip pocket, preventing clogging and enhancing work efficiency.

Structure of Carbide Rotary Bars

Master cemented carbide bars feature various blade shapes including cylindrical, round-tip cylindrical, elliptical, bullet, spherical, and conical structures. The blade type is selected based on the shape of the area to be machined.

1. Cylindrical Type

The blade has a flat tip and is held on the outer circumference, typically pressed perpendicularly for processing. Some products feature a bladed tip for axial processing.

2. Round-Tip Cylindrical Type

Featuring a rounded blade tip, suitable for processing curved surface corners and sides similar to the cylindrical type.

3. Oval Type

With a rounded blade throughout, suitable for machining curved surfaces evenly.

4. Cannonball Type

Featuring a thin blade tip resembling a cannonball, ideal for processing intricate shapes and detailed areas.

5. Sphere Type

Utilizing a spherical blade for machining round grooves.

6. Conical Type

Conical blades with angles of 60° or 90° for machining V-grooves and countersunk grooves are also available in inverted conical shapes.

Other Information About Carbide Rotary Bars

Material of Blade

The blade of the master cemented carbide bar is typically made of cemented carbide, while the shank can be composed of either cemented carbide or iron. Master cemented carbide bars made entirely of cemented carbide are known as “all cemented carbide type.”

The shank diameter options include 3 mm, 6 mm, and 8 mm, with 6 mm being the most common size. The 3 mm shank is suitable for precision machining, while the 8 mm shank is used for machining with larger removal volumes.

Recommended rotation speeds are provided as specifications. Using a grinder with an incorrect rotation speed may lead to chattering and clogging. It is essential to verify the recommended rotation speed and select the appropriate master carbide bar to match the rotary tool being used.