What Is a General Purpose Milling Cutter?

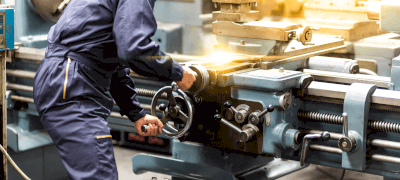

A general-purpose milling cutter is a machine tool in which cutting tools such as milling cutters and end mills are mounted on a rotating shaft called the spindle. The cutting tool cuts the surface of the material while rotating the tool.

A general-purpose milling cutter is a machine tool in which cutting tools such as milling cutters and end mills are mounted on a rotating shaft called the spindle. The cutting tool cuts the surface of the material while rotating the tool.

Cutting tools remove chips from the material surface by rotating the tool blade around the axis of rotation, creating a contact surface with the material, and removing chips along the contact surface. End mills have a cutting section at the tip and can machine holes in a direction perpendicular to the axis.

The tool position, direction of travel, depth of cut, and feed rate required for machining must be adjusted manually by the operator on a non-mechanized general-purpose milling cutter. On the other hand, with NC milling machines, which incorporate numerical control technology, these adjustments can be made automatically by computer.

Uses of General Purpose Milling Cutters

General-purpose milling cutters are widely used machine tools for cutting materials and have a wide range of applications. For example, in addition to machining flat and curved surfaces, they can also be used for drilling, step machining, and groove cutting. In addition, although metal is often used as the work material, it is used for a wide variety of materials of any size that can be fixed to the milling machine.

Milling machines and end mills are used as tools. Compared to milling machines, end mills have a greater variety of cutting edges and shapes, and are used when more detailed cutting is required. It is important to select the most suitable tool for the machining purpose.

Unlike NC milling cutters equipped with CNC (computer numerical control) functions, general-purpose milling cutters require the operator to adjust the position of the tool and material manually, relative feed rate, and cutting depth.

In general, general-purpose milling cutters are widely used mainly in the manufacturing industry, but their use is not limited; they can also be used for DIY and hobby machining, allowing simple machining without the need for specialized knowledge.

Principle of General Purpose Milling Cutter

General-purpose milling cutters are manually operated, allowing the operator to process material while adjusting the position of the tool. Conditions that can be adjusted by the operator include tool position, speed, and depth of cut. General-purpose milling cutters excel in manual operation and allow the operator to have a degree of freedom in machining.

NC milling machines build machining programs by importing 3D CAD data. As a result, material processing of complex shapes can be automated. General-purpose milling cutters, on the other hand, are capable of machining in small quantities and reflecting the skill of the operator.

To begin with, a milling machine is a machine tool that cuts and processes materials. It consists of a drill blade attached to a rotating shaft. The drill blade can be used to machine the flat or curved surface. In most cases, metal materials are used as the processing material. They are used for a variety of materials such as aluminum, brass, and stainless steel, all of which are of a size that can be fixed to the milling machine.

In addition, a tool called an end mill is used with the milling machine. Compared to milling, end mills have a greater variety of cutting edges and shapes, and are suitable for more detailed cutting operations. The most suitable tool should be selected according to the purpose of machining.

Types of General Purpose Milling Cutters

A general-purpose milling cutter is a type of machine tool that can cut materials in a way that is manually operated by the operator. The types can be broadly classified into two categories:

1. Horizontal Milling Machine

Horizontal milling machines are a type of milling machine that places material on a table and performs machining in a horizontal direction, with the tool moving from side to side. Horizontal milling machines can process large materials and are used for manufacturing parts for ships, aircraft, and automobiles. They are also highly efficient and safe because the operator does not need to get close to the material.

2. Vertical Milling Machine

Vertical milling machines are a type of milling machine that performs machining vertically, with the tool moving up and down. Vertical milling machines are widely used in the machining field because they can process small and medium-sized materials. They can also process materials standing vertically and are excellent for drilling and groove cutting.