What is a Photon Counter?

A photon counter is a sophisticated electronic device used for counting photons, the smallest units of light. This technology is essential in scenarios where capturing and counting minuscule amounts of light from an object is critical for analysis.

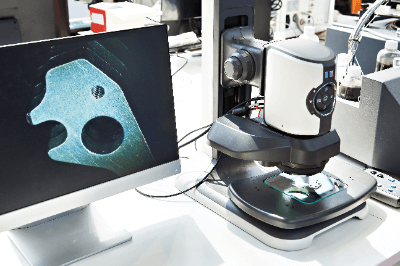

Photon counting enables the observation of objects by individually counting photons and analyzing their energy in completely dark environments. This process involves a detector for photon detection, an amplification unit for signal enhancement, and a counting unit, which is the photon counter itself, to process and digitize the signal for further analysis.

Uses of Photon Counters

Photon counters are integral in fields where detecting small amounts of light is necessary. They are used in photoluminescence, electroluminescence, chemiluminescence, and bioluminescence studies. In medical applications, photon counting CT technology stands out for its ability to perform scans with lower X-ray radiation levels than traditional methods.

Principles of Photon Counters

Photon counters operate by capturing light in minimal quantities and analyzing both the quantity and energy of photons. These devices process signals from single-photon detectors, which produce a pulsed signal upon photon entry. An amplifier, either independent or integrated into the detector or counter, amplifies this signal.

The number of signals per unit time indicates the light’s intensity, while the signal size reflects the energy of individual photons. These counters convert analog signals into digital data for analysis on a PC, making the matching performance and characteristics of the detector and amplifier crucial.

How to Choose a Photon Counter

When selecting a photon counter, time resolution is a key performance metric. This resolution determines the ability to separate and measure individual photons when they arrive in rapid succession. The lowest time resolution among the detector, amplifier, and counter components limits the system’s overall performance. Hence, ensuring compatibility and matching performance characteristics among these components is vital for optimal functionality.