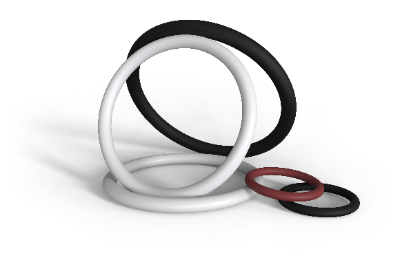

What Is a Rubber Gasket

In engineering terms, sealing material used for rotating parts is called “packing” and sealing material used for stationary parts is called “gasket”, but rubber gaskets generally refer to rubber sealing material used for stationary parts.

In engineering terms, sealing material used for rotating parts is called “packing” and sealing material used for stationary parts is called “gasket”, but rubber gaskets generally refer to rubber sealing material used for stationary parts.

Uses of Rubber Gaskets

Rubber gaskets are used not only in industrial and laboratory equipment, but also in many aspects of daily life, such as the lids of various containers, shower nozzles, and water pipes in the home.

For example, they are used at joints of pipes and valves to improve airtightness and liquid-tightness of these parts, preventing internal fluid leakage and contamination by foreign substances.

Principle of Rubber Gaskets

Rubber gaskets, as the name suggests, are made of rubber, and their function is achieved due to the rubber’s ability to expand and contract.

Rubber stretches because the macromolecules that make up the rubber are stretched by external forces, but the sulfur atoms maintain the connection (cross-linking) between the molecules and keep them together.

For this reason, even when rubber is stretched by external force, it will stretch without tearing up to a certain degree of external force.

On the other hand, when the external force is removed, the rubber returns to its original state and shrinks.

In addition, when the fluid stops flowing, only the external force in the vertical direction of the drawing is applied to the rubber packing due to the tightening of the piping, and the rubber packing returns to its original shape, and the external force from the fluid is applied again. It can be used repeatedly because it exhibits the same function once it is added.

The external force in the radial direction of the pipe caused by the pressure of the fluid flowing inside the pipe will cause the inner diameter side of the rubber gaskets to shrink in the radial direction, and it will also expand in the longitudinal direction of the pipe, which is the direction in which the liquid flows.

The rubber gasket expands and contracts to fill the gap in the piping, thus preventing leakage of fluid to the outside and contamination of foreign matter from the outside.

When the fluid stops flowing, rubber gaskets are subjected to external force only in the vertical direction, and the rubber gasket returns to its original shape and can be used repeatedly as it performs the same function when external force is applied again.

This property allows the rubber packing to be used in joints such as piping, as well as in areas that are opened and closed repeatedly, such as container lids.

However, since rubber gaskets cannot completely return to their original shape, their function will gradually deteriorate.

For this reason, they should be used within a certain period and replaced when they deteriorate.

Manufacturing Process of Rubber Gaskets

Rubber gaskets are manufactured in a variety of materials at a lower cost than sealing tape or other sealing materials.

Rubber gaskets can be manufactured in two ways: by punching rubber sheets into a predetermined shape or by injection molding using a die.

When a die is used, complex shapes such as a double ring can be manufactured.

Material of Rubber Gaskets

Various types of rubber can be used for rubber gaskets, and it is important to select the appropriate material depending on the type of fluid, temperature, and other factors.

Synthetic rubber is more commonly used for rubber gaskets than natural rubber.

Fluoro Rubber (FKM), Urethane Rubber (U), Silicone Rubber (VMQ), Ethylene-Propylene Rubber (EPDM), Butyl Rubber (IIR), Styrene-Butadiene Rubber (SBR), etc.

Types of Rubber

1. Nitrile rubber (Nbr)

Nitrile rubber is one of the most common synthetic rubbers and is a material with excellent oil resistance, abrasion resistance, and aging resistance, making it the first rubber to be considered as a packing material for situations where oil resistance is required.

Nitrile rubber also has excellent aging resistance, making it suitable for use in parts that will be used for long periods.

On the other hand, it is not suitable for use in places exposed to direct sunlight because of its weak weather resistance.

2. Fluoro Rubber (FKM)

Compared to other rubbers, fluoro rubber has superior heat resistance, oil resistance, weather resistance, and chemical resistance.

For this reason, it is often used for packing in situations where chemicals are used.

However, fluorinated rubber is susceptible to physical shock, so care must be taken when handling it.

3. Urethane Rubber (U)

Urethane rubber has high abrasion resistance and overall mechanical strength, which are its greatest characteristics and is suitable for packing used in environments with a lot of friction.

On the other hand, its weak water resistance makes it less suitable for use in wet or humid environments.

In addition, the shelf life is about 10 years.

4. Silicone Rubber (VMQ)

The greatest feature of silicone rubber is its low impact on the human body.

It also has excellent heat resistance and flame resistance, and its shape does not change depending on temperature.

Since its price is relatively stable, it is often used in household products. Taking advantage of its safe characteristics, it is used in packing for rice cookers and products around water.

5. Ethylene Propylene Rubber (EPDM)

Ethylene-propylene rubber is a material with excellent resistance to weather, cold, and inorganic chemicals.

Originally, rubber was susceptible to direct sunlight and extreme cold, and became hard and crumbly, but EPDM has excellent weather and cold resistance, so it can be used outdoors without problems.

Ethylene-propylene rubber is used for rubber electric wires used outdoors. However, its oil resistance is weak, so it is a versatile material for use in environments where oil resistance is not required.

6. Butyl Rubber (IIR)

Butyl rubber is made by copolymerizing isobutylene with a small amount of isoprene. It has excellent anti-vibration, insulation, water, weather, chemical, and heat resistance.

It has a wide range of uses, from industrial products to household goods, and is an indispensable material for daily life.

7. Styrene Butadiene Rubber (SBR)

Styrene-butadiene rubber has excellent properties against animal and vegetable oils such as ethylene glycol and brake oil.

It also has superior resistance to abrasion and aging compared to natural rubber and is an inexpensive material.

It also has the advantage of being resistant to heat and easy to produce homogeneous products and is widely used in tires and hoses.

Conclusion

Rubber gaskets are used in various applications such as plumbing and household goods, and their characteristics vary greatly depending on their materials, shapes, and manufacturing methods.

It is necessary to use rubber gaskets made of materials, shapes, and manufacturing methods suitable for the materials and shapes to suit the use environment and applications.

In consideration of durability, it is also necessary to replace them when necessary.