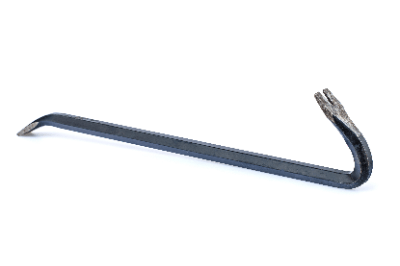

What Is a Bar?

A bar, also known as a crowbar, is a steel tool primarily used for removing large steel nails, typical in construction projects. It features a simple design with a split end for gripping nails and an L-shaped bend for leverage. This design allows for efficient nail extraction when force is applied to the L-shaped part.

Besides being a nail puller, its steel construction makes it sufficiently heavy to function as a hammer. There are three main types of bars, each designed for specific applications.

Uses of Bars

Bars are commonly employed in carpentry, especially for nail removal during house demolitions or renovations. They enable the separation of nails from wood with minimal effort, making them a practical tool for DIY projects at home. Additionally, bars are useful for opening packing boxes, dismantling woodwork, and other similar tasks.

Principle of Bars

Bars vary in size, with larger ones around 60 cm for bigger nails and smaller ones as short as 25 cm for lighter tasks. The appropriate size should be selected based on the application. There are three primary types of bar shapes:

- Flat bars: Characterized by a split tip on one end and a thin, flat blade on the other. The flat bar is versatile for prying and lifting nails, making it the standard bar shape.

- Kajiya (blacksmith’s forge): This type has split tips on both ends, with variations including an L-shaped bend for added functionality as a hammer. The kajiya is particularly effective for raising nails.

- Santoku nail clamp: Known for its thin, pointed tip, this bar is dual-purpose, serving as a nail clamp and a hammer.

Bars are recognized as designated intrusion tools, and thus, carrying them concealed without a valid reason is legally prohibited.

How to Use Bars

Bars, being heavy and made of steel, can be hazardous if not used correctly. Here are some guidelines for safe usage:

1. To expose the head of a nail in the wood, use the bar to tap the nail head lightly. This initial step makes the nail easier to pull out.

2. Insert the exposed nail into the split end of the bar.

3. Apply leverage to extract the nail. Using pliers for final removal is advisable for nails longer than 40 mm.

How to Choose Recommended Bars

Bars come in various lengths and shapes, each suited for different purposes. Here are some recommendations:

1. Flat bar: A conventional type known for its ease of grip, particularly suited for general use.

2. Hexagonal and octagonal bars: These bars offer a firm grip and are ideal for emergencies, thanks to their unique cross-sectional shapes.

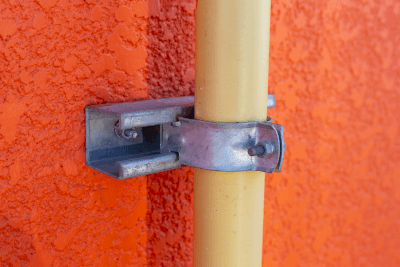

3. Pipe disassembly crowbar: Lightweight and ideal for prolonged use, these bars are recommended for hobbyists and DIY enthusiasts.

A hand wire cutter is a specialized type of

A hand wire cutter is a specialized type of