What Is an Oil-Filled Transformer?

An oil-filled transformer is a transformer that uses oil as an insulating material.

The primary insulating oil is mineral oil. A transformer is a device that uses two coils to convert voltage. These coils, known as the primary and secondary windings, determine the voltage conversion ratio.

There are various types of transformers, but oil-filled transformers are the most widely used in power supply applications.

Applications of Oil-Filled Transformers

Oil-filled transformers are used in numerous applications, especially in power transmission and distribution. Electricity produced in power plants is typically high voltage.

This high-voltage power is transmitted over towers and other structures to the transmission lines. Oil-filled transformers convert this high-voltage power for use in low-voltage distribution lines.

The transformed low-voltage power is then distributed to locations such as homes, factories, and commercial facilities. Oil-filled transformers at these sites adjust the voltage to levels suitable for local demands, such as 100 VAC or 200 VAC for households and 200 VAC or 400 VAC for industrial and commercial settings.

Principle of Oil-Filled Transformers

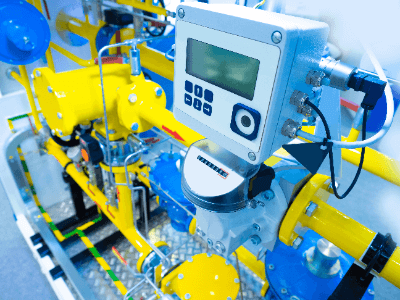

An oil-filled transformer comprises an iron core, coils, an oil tank, and insulating oil.

1. Iron Core

The iron core, situated at the transformer’s center, is constructed by laminating silicon steel plates and other materials to create a magnetic circuit. This multilayer structure reduces magnetic losses, enabling efficient power conversion.

2. Coil

The high-voltage and low-voltage windings are wrapped around the iron core. Made from copper or aluminum wire, these windings generate a magnetic field when current flows through them. In step-down transformers, the high-voltage side has fewer windings compared to the more numerous windings on the low-voltage side.

3. Oil Tank

The transformer’s components are enclosed within a steel tank, filled with insulating oil. This oil not only insulates the interior but also helps in cooling. Tanks often have fins to facilitate the circulation of the cooling oil and heat dissipation.

4. Insulating Oil

Mineral oil is commonly used as the insulating oil in oil-filled transformers. However, environmentally friendly alternatives like sunflower or rapeseed oil are also in use. These oils, while more expensive, help prevent environmental pollution in case of leaks. Monitoring the concentration of organic gases in the insulating oil helps assess transformer conditions. Overheating produces gases like ethylene and ethane, while partial discharge generates acetylene and hydrogen. Acetylene, especially, is an indicator of internal transformer abnormalities and should not be present even in trace amounts.

Types of Oil-Filled Transformers

Oil-filled transformers are categorized into self-cooled and forced-cooled types.

1. Self-Cooling Type

Self-cooled transformers use internal oil and a cooling system for natural heat dissipation. Radiators or similar devices attached to the tank aid in this process. They are commonly used in power transmission and distribution systems.

2. Forced Cooling Type

Forced-cooled transformers have a cooling system that actively circulates oil. This enhanced cooling method is suitable for high-load or high-temperature environments, often involving pumps or fans for oil circulation.

Other Information on Oil-Filled Transformers

1. Allowable Temperatures for Oil-Filled Transformers

Excessive heating in oil-filled transformers risks insulation failure and potential fires. Therefore, maintaining the operating temperature below the permissible limit is crucial. The general maximum allowable temperature is 105 °C, but it is typically controlled to remain around 95 °C or lower, considering external influences and temperature differences.

2. Treatment of Oil-Filled Transformers Under the Fire Service Law

Mineral oil in oil-filled transformers, usually classified as Petroleum No. 3, becomes a hazardous material under the Fire Service Law when the volume exceeds 2,000 liters. However, when connected to an electrical circuit, it falls under the Electricity Business Law and is not treated as a hazardous material. If disconnected from the power line, such as during dismantling, it reverts to being a hazardous material. Specific circumstances require consultation with the fire department or relevant authorities.