What Is a Corrosion Prevention Film?

Corrosion prevention film is a film mixed or coated with a rust inhibitor, or a film that suppresses rust by preventing oxygen and water vapor. Vaporizable rust inhibitors are used as rust inhibitors.

Rust prevention is an important issue for quality control of metal products. Conventionally, coatings with grease or oil have been used to prevent rust. These coatings had to be removed before processing or assembly, which involved labor and equipment costs and environmental impact. Corrosion prevention film eliminates these problems because it prevents rust without the use of rust prevention oil. For films that prevent oxygen and water vapor, the burden on the environment is even smaller because no corrosion prevention agents are used in the film.

Uses of Corrosion Prevention Films

Corrosion prevention films are used to prevent rust on metal products. Those for steel are often used, but there are also those for non-steel.

Uses of automotive parts storage are a specific example. Automobile parts are often stored for long periods of time and are metal products that require special rust prevention. Conventionally, they were stored in double packaging: rust-proof paper for rust prevention and plastic bags for sealing. Corrosion prevention film can be sealed by heat sealing, so a single sheet can perform these functions and reduce costs.

Larger sheet types are commercially available and can be used for packaging large machinery.

Principle of Corrosion Prevention Films

Corrosion prevention film is made of polyethylene or other plastic containing an evaporative rust inhibitor. This vaporizable rust inhibitor is effective in preventing rust.

When the vaporizable rust inhibitor evaporates from the corrosion prevention film, it fills the space sealed by the film. During this process, the vaporizable rust inhibitor dissolves into the surface of the wrapped metal and the moisture in the space. The dissolved rust inhibitor suppresses the electrochemical reaction that causes rust, making rust less likely to occur.

Since the rust inhibitor is vaporizable, it can penetrate into minute crevices that cannot be reached by coating methods, such as application, and rust can be prevented in every nook and cranny.

Depending on the type of rust inhibitor, the reaction mechanism of rust prevention varies. For example, nitrites used in corrosion prevention films for steel, for example, inhibit the reaction of oxygen and water with metal by dissolving into condensing water. Carboxylates of amines, also used for steel, dissociate into amine and carboxylic acid and then reattach on the surface of the metal, thereby exhibiting rust inhibiting effects.

For barrier types that do not contain vaporizable rust inhibitors, the rust inhibiting effect is achieved by preventing oxygen and water vapor from entering the bag. Generally, rusting occurs rapidly when humidity exceeds 60-70%, so it is important to prevent moisture from entering the bag to avoid such high humidity.

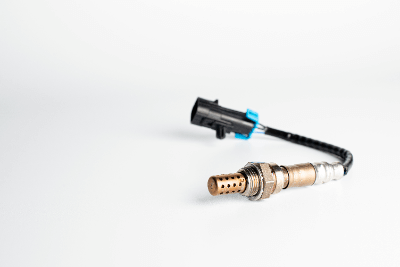

An oxygen sensor is a sensor that measures the concentration of oxygen in the atmosphere of a measurement space.

An oxygen sensor is a sensor that measures the concentration of oxygen in the atmosphere of a measurement space.