What Is an ALD System?

An ALD system is a technology that creates nano-scale thin films through the atomic layer deposition technique. Known for its precise control of film thickness and dense, step-by-step film coating, ALD can be slow in deposition speed. It often uses organometallic materials, which can be harmful and flammable, necessitating careful handling and specialized knowledge.

An ALD system is a technology that creates nano-scale thin films through the atomic layer deposition technique. Known for its precise control of film thickness and dense, step-by-step film coating, ALD can be slow in deposition speed. It often uses organometallic materials, which can be harmful and flammable, necessitating careful handling and specialized knowledge.

Uses of ALD Systems

ALD systems are integral in semiconductor and flat panel display (FPD) production, particularly in DRAM manufacturing. Applications include:

- Gate Oxide Films for transistors.

- Barrier Films to prevent metal contamination and insulation degradation.

- Anti-permeation Films for OLED panels and other applications.

They are also used in the biomedical industry for coating artificial joints and bones and in drug delivery systems.

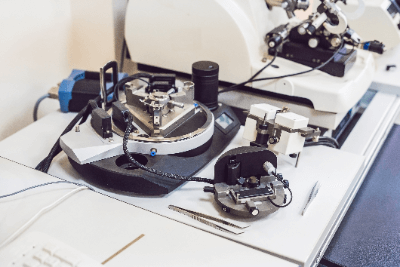

Principle of ALD Devices

An ALD system typically consists of a vacuum chamber, material gas supply and exhaust parts, and a control unit. The process involves introducing a precursor into the chamber, adsorbing it onto the substrate, and then oxidizing or nitriding it to form a thin film. This cycle is repeated to deposit multiple atomic layers. Effective purging is crucial to prevent film quality degradation due to residual precursors or oxidation sources. Thermal ALD and plasma ALD are two methods to enhance deposition efficiency.

Other Information on ALD Systems

1. Difference Between ALD, CVD, and PVD

While ALD is similar to CVD, the key difference lies in ALD’s ability to deposit films one layer at a time. PVD, on the other hand, physically deposits material particles. Compared to CVD and PVD, ALD excels in depositing films on narrow and deep structures, particularly effective in coating objects with many small pores.

2. Global Market for ALD Systems

The global ALD market is expected to reach $6.5 billion by 2028. Although CVD currently dominates the thin film deposition market, ALD plays a vital role in semiconductor manufacturing due to its superior deposition capabilities and is anticipated to continue growing in importance.