What Is Polyimide Tape?

Figure 1. Image of polyimide tape

Polyimide tape is an adhesive tape that uses polyimide film as the tape base material.

Polyimide has excellent heat resistance and insulation properties due to its high thermal decomposition temperature. Its main applications are heat-resistant masking of electronic substrates and heat-resistant insulation.

Polyimide is a general term for polymers that are polymerized by imide bonds. The first industrial application of polyimide film was commercialized by DuPont of the United States, which used aromatic polyimide.

Many polyimide tape products use a silicone adhesive, which has the advantage of leaving no adhesive residue after removal.

Uses of Polyimide Tapes

Polyimide tape is mainly used under high temperatures and high voltages due to the ultra-high and ultra-low temperature resistance of the base material, polyimide film. It can be applied in a variety of places, from repairing railroad and aircraft parts that require heat resistance to insulating circuits.

Many of them are thin and translucent, making them suitable for repairing small parts and fine electronic circuits. Since it is removable again, it can also be used in situations where repeated fine adjustments are required. Common uses include masking electronic circuits during soldering operations and insulating and insulating printed circuit boards.

In addition, since many products have high chemical resistance, they are often used for fixing when applying strong acidic chemicals or for protection during partial etching.

Principle of Polyimide Tapes

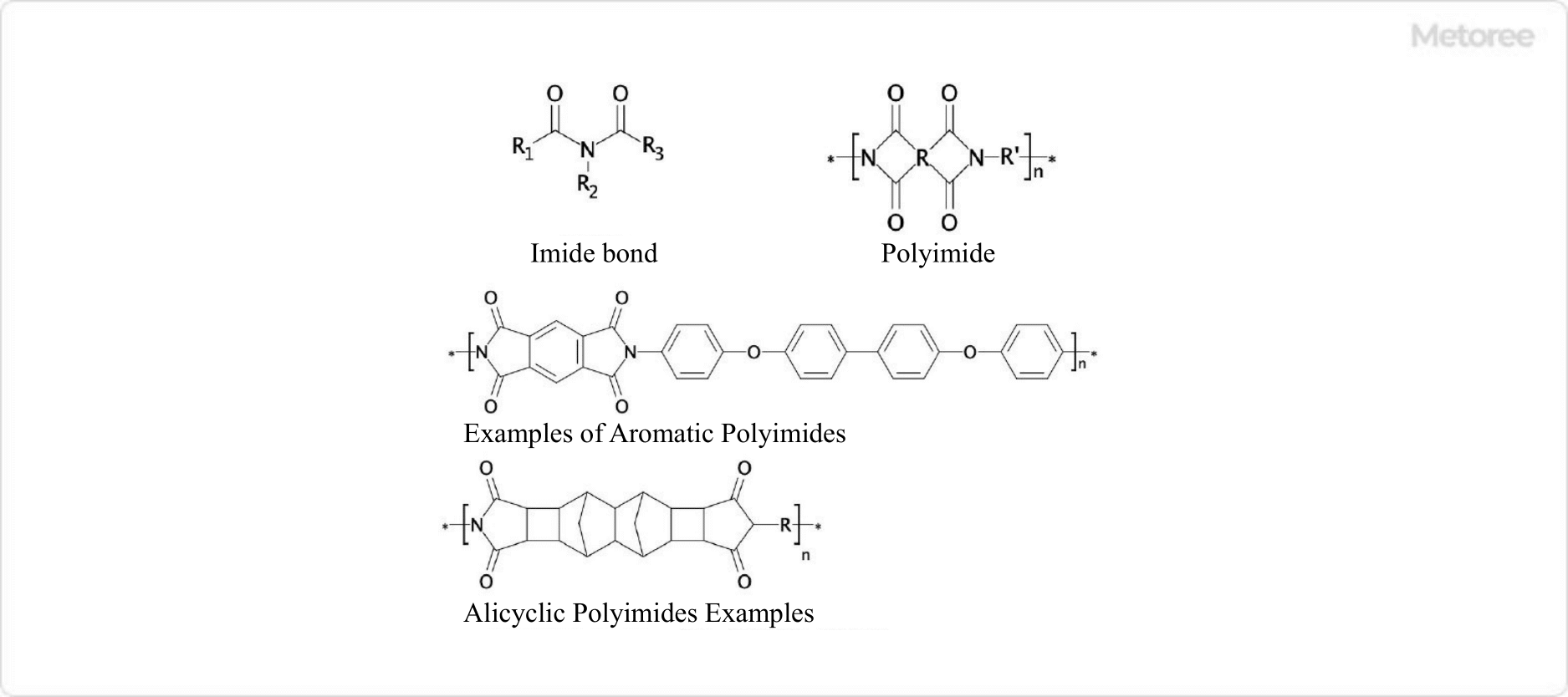

Figure 2. Imide bonding and polyimide

The majority of polyimide tape consists of a polyimide film coated with a silicone adhesive. Some rubber-based adhesive products and acrylic adhesive products are also available for applications where silicone residue must be prevented.

Polyimide tape is characterized by the properties of the polyimide film and adhesive. Since polyimide has a higher heat resistance temperature than the adhesive, the heat resistance temperature of the product is generally determined by the type of adhesive.

Properties of Polyimide

Polyimide is a general term for high-molecular compounds that are polymerized by imide bonds. Polyimide tape is made of aromatic polyimide, which is a polymer of aromatic compounds polymerized by imide bonds. Because of the extremely strong bonding, polyimide tape has high strength and excellent heat resistance and insulation properties. The thermal decomposition temperature is 500°C or higher.

The specific properties of the molecular structure that give it excellent heat resistance are as follows:

- Aromatics are conjugated to each other via imide bonds.

- The aromatic rings are located in the same plane and the molecular chains are tightly packed together.

- Highly polar imide bonds have strong intermolecular forces.

It also has a low expansion coefficient when heated, so it does not expand much even when used at high temperatures, thereby minimizing dimensional errors.

Other Information on Polyimide Tape

Adhesives for Polyimide Tape

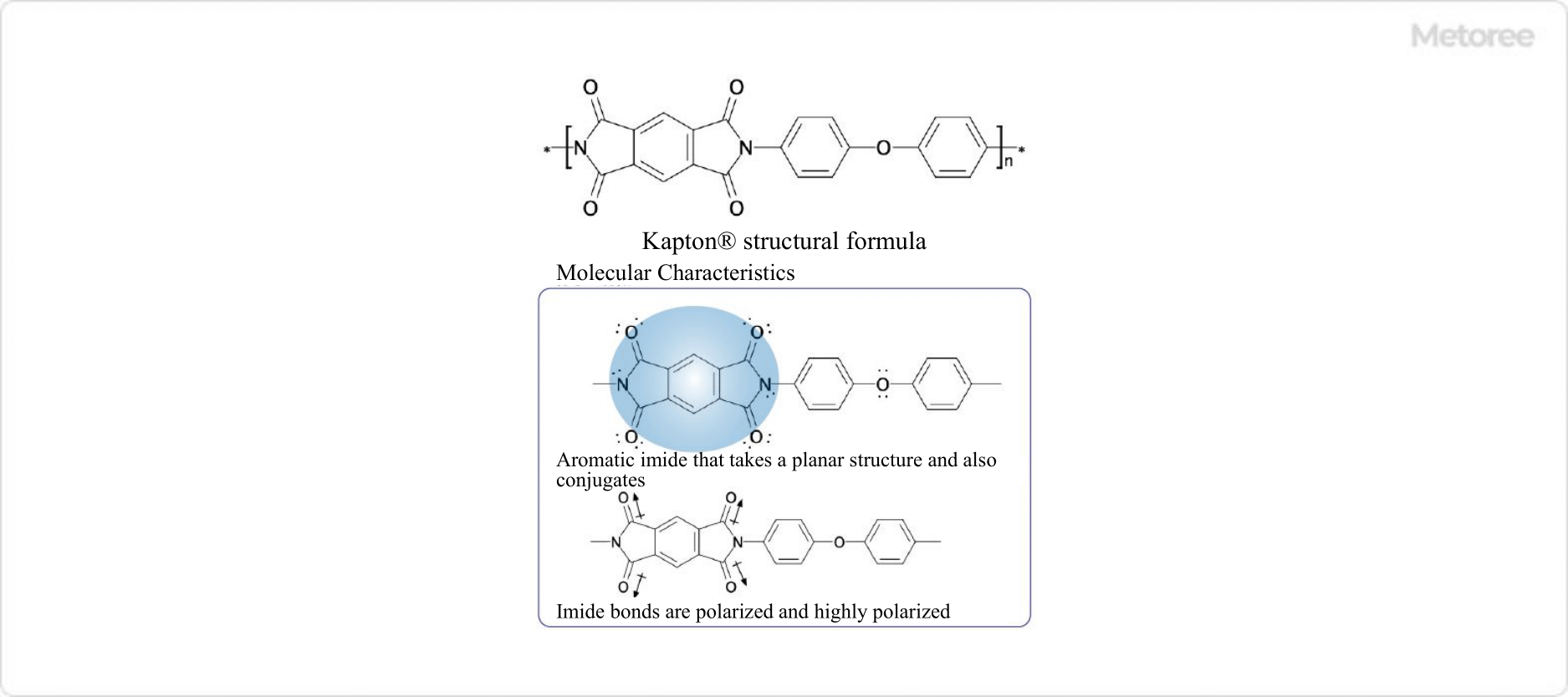

Figure 3. Kapton® Structure and Characteristics

Adhesives used in polyimide tape include silicone adhesive, rubber adhesive, and acrylic adhesive, each with different properties such as adhesive strength and heat resistance. Among polyimide tape, products using the polyimide film Kapton® by E.I. du Pont de Nemours and Company (DuPont) of the United States are sometimes called Kapton® Tape.

1. Silicone Adhesive

Silicone adhesives are adhesives consisting of silicone rubber and silicone resin components. Although silicone rubber does not have high adhesive properties, it has excellent cold and heat resistance. As a result, it can be used in a wide range of temperatures, from -60°C to 250°C.

Silicone resin is an adhesive agent component that complements the adhesive properties of silicone rubber. By changing the composition ratio of the silicone rubber component to the silicone resin component, the required adhesive properties can be obtained. Cross-linking agents such as benzoyl peroxide are also used to further improve heat resistance from the original properties.

Adhesion to silicone rubber and fluororesin is also possible, and it has excellent water and chemical resistance. It can also be used in places where it is exposed to strongly acidic aqueous solutions. Another advantage is that air bubbles do not easily form when applying the film because it is easy to release air. It also has excellent removability, so it can be peeled off without leaving adhesive residue.

2. Non-Silicone Adhesives

Polyimide tape with acrylic or rubber-based adhesive is also available, although not in large numbers. Although inferior to silicone-based adhesives in terms of heat resistance, they are used to prevent soldering defects caused by siloxane gas or silicone residue. It is used for masking during reflow soldering of electronic components, temporary fixing, protection of components and lenses, and transportation of components.