What Is a Torx Screwdriver?

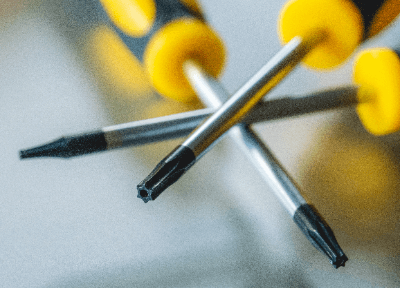

A Torx screwdriver is a screwdriver specially designed to handle Torx screws.

A Torx screwdriver is a screwdriver specially designed to handle Torx screws.

Torx is a screw with a hexagonal star-shaped groove on the screw head. It is a screw standard developed by Textron Kamker, Inc. in 1967, and is now a registered trademark in the United States.

Since the name “Torx” is not commonly used, the international standard ISO 10664 defines it as “hexalobular internal.” It is sometimes called a hexrobe.

The common name for a Torx screwdriver is a star driver or star screwdriver.

Principle of Torx Screwdrivers

The principle of the Torx screwdrivers is based on the shape of the Torx screwdrivers, which is efficient in transmitting torque.

In the case of a standard cross or hexagonal groove, the groove shape is linear. When torque is applied with the tool, the torque is applied by point contact because there is rattling between the groove and the tool. In the case of torques, the shape of the groove consists of curves, resulting in surface contact and torque can be easily transmitted.

In addition to the efficiency of torque transmission, the advantages of torques are as follows:

- The tool does not easily slip out of the groove when tightening.

- Durability against abrasion and cracking/chipping due to surface contact

- Good design due to the hexagonal star shape

Uses of Torx Screwdrivers

Torx screws have a hexagonal star-shaped groove on the screw head, which allows the Torx screwdrivers to engage the screw and transmit force more efficiently. In Europe, Torx screws are becoming more common than Phillips screws, and are used in many European-made automobiles and motorcycles.

Until a few years ago, Torx screws were not widely used, and few people used Torx screwdrivers for such purposes as preventing disassembly. In recent years, however, the number of Torx screwdrivers sold has increased, and they have become more common, and their effectiveness has almost disappeared.

Some, such as the “tamper-resistant Torx screwdrivers,” have a projection in the center of the Torx groove to prevent disassembly except with a special tool.

How to Select Torx Screwdrivers

Torx screwdrivers are selected according to screw size, screw shape, grip shape, shaft material, etc., depending on the purpose of use.

1. Screw Size

The size of the hexagonal star-shaped groove on the end of Torx screwdrivers generally ranges from T4 to T40. The larger the number after the T, the larger the screw head.

The Torx screwdrivers must be the same size as the Torx screw, as using the wrong size, Torx screwdrivers will damage the Torx screw.

2. Screw Shape

There are several types of Torx screw shapes, and special Torx screwdrivers are used.

- Security Torx (Torx TR)

There is a projection in the center of the groove for tamper resistance. - Torx Plus

Torx Plus has a rounded groove corner for higher torque and wear resistance. - Torx TS

This is a tamper-resistant version of the above Torx Plus.

A tamper-proof function was added to the above Torx Plus.

3. Grip Shape

As with general screwdrivers, there are various grip shapes, including thickness, length, dimpled, and T-shaped grips. Select a grip shape that best suits your application, such as ease of force application and workability.

4. Shaft Material

Torx screwdrivers are made of iron, stainless steel, chrome vanadium steel, and other materials. Selection should be based on the same criteria as general screwdrivers and should be suited to the Torx screw material and screw size.