What Is a Contact Pressure Gauge?

A contact pressure gauge is a product that incorporates an electrical contact mechanism (a mechanism that allows/stops the flow of electric current through physical contact/disconnection of the current circuit) in addition to the function of displaying the measured pressure on an indicator by means of an element (pointer) as a pressure gauge.

A contact pressure gauge is a product that incorporates an electrical contact mechanism (a mechanism that allows/stops the flow of electric current through physical contact/disconnection of the current circuit) in addition to the function of displaying the measured pressure on an indicator by means of an element (pointer) as a pressure gauge.

In addition to the ability to read the measured pressure, the contact mechanism electrically turns ON/OFF when it judges whether the pressure set by the user in advance has been reached. This ON-OFF signal can be used to perform various operations in control systems.

Uses of Contact Pressure Gauges

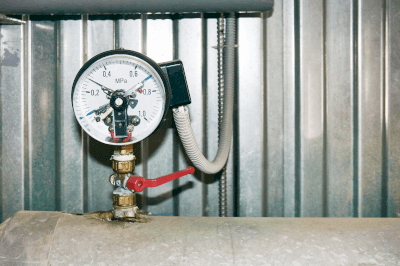

Contact pressure gauges are commonly used in industries that handle various fluids and gases and are used in various situations to display and operate the pressure value to be detected.

Monitoring, detecting, and displaying abnormalities in pressure as ON-OFF signals such as buzzer emission and lamp lighting can be used to predict danger and ensure safety.

In addition, when used as a control pressure switch together with a control relay, among others., as a control system, it enables more accurate pressure monitoring, adjustment, and control.

The pressure can be set to turn ON/OFF at the upper or lower limit of the pressure value to be detected.

For example, when a pressure of 5.0MPa or higher is detected, a buzzer will sound and an alarm lamp will flash to warn of danger, and the control system will close the valve to stop fluid flow and avoid danger.

Principle of Contact Pressure Gauges

The detection of the set pressure in contact pressure gauges can be mechanical or electronic, depending on the structure of the contact mechanism and the actuation method.

- Mechanical type

The contact mechanism is turned on and off by physical contact/disconnection of the contact point. The contact mechanism is activated when the displacement detected by the pressure gauge reaches the set pressure. Among mechanical types, the following types are available depending on the contact mechanism.

- Pressure gauge with contact pressure gauge

The pressure introduced by the Bourdon tube or bellows contact (both are pressure detection mechanisms of pressure gauges) built into the pressure gauge is detected and displaced. The detected displacement is indicated by an element (pointer) on the scale plate of the pressure gauge using an expansion mechanism. The displacement of the element (pointer) directly activates the contact mechanism of the low-contact pressure switch, turning it ON and OFF. - Microswitch contact pressure gauge

The displacement detected by the operation of the Bourdon tube built into the pressure gauge activates the contact mechanism of the microswitch to turn it ON and OFF. As a feature, there is no chattering (a phenomenon in which the contact repeats ON-OFF in a short period of time) when the contact is activated, and the pressure gauge can be used even in locations with some vibration. - Reed switch contact pressure gauge

The displacement detected by the Bourdon tube of the pressure gauge activates the contact mechanism of the reed switch to turn it on and off. The pressure gauge is compact, lightweight, and can be installed in a small space. The reed switch is not easily affected by the external environment and has excellent reliability.

- Electronic Contact Pressure Transducers

ON-OFF is performed by a combination of a pressure sensor and a semiconductor relay. Since the contact mechanism is not mechanically actuated, there are no malfunctions, and thus higher accuracy, durability, and reliability can be achieved.