What Is an IC Tray?

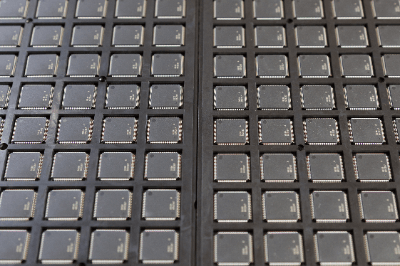

An IC tray is a special container used to safely transport, inspect, store, and ship semiconductor IC packages.

An IC tray is a special container used to safely transport, inspect, store, and ship semiconductor IC packages.

IC packages come in various external shapes, including SOPs and QFPs with lead frames protruding from the sides of the package, BGAs with solder arranged in a grid pattern on the bottom of the package, and PGAs with pins arranged in a grid pattern on the bottom of the package.

In order to handle IC packages safely, it is important to use the appropriate IC tray, taking into consideration the type and size of the package and the location where it is used.

Uses of IC Trays

IC Trays are used in the back-end process of semiconductor manufacturing plants, where chips on silicon wafers are separated and packaged.

After the process of encapsulating chips in packages, IC packages are packed in IC trays and transported to the inspection process. After the inspection, the IC packages are stored and shipped in the IC trays.

In this way, IC trays are always used in the packaging process at semiconductor manufacturing plants.

Features of IC Trays

Semiconductor products are generally susceptible to ESD damage caused by static electricity.

In addition, during the reflow process of mounting semiconductor ICs on boards, if moisture is contained inside the IC package, the heat during reflow may cause the moisture inside to expand and destroy the mold resin. Semiconductor ICs are mounted on the board to remove moisture.

JEDEC standard trays, which conform to JEDEC (Joint Electron Device Engineering Council) standards, are available as IC trays that meet these requirements.

JEDEC standard trays guarantee characteristics such as heat resistance and anti-static measures.

JEDEC standard trays are available in various external sizes according to the type and size of IC packages. However, one of the corners is cut at a 45° angle so that the single pin position of the IC can be identified. Therefore, ICs can be picked up and fed directly into JEDEC-standard equipment, thereby improving production efficiency.