What Is a Turbojet Engine?

A Turbojet Engine is an engine that derives thrust from the exhaust flow of combustion gases.

It is the most fundamental form of jet engine and was developed in the early stages of aviation. A turbojet engine is a type of gas turbine engine used in aircraft, harnessing the energy of high-temperature, high-pressure gases created within the engine to achieve high-speed jet propulsion.

By utilizing the reaction from this process, aircraft can attain substantial thrust, enabling high-speed flight.

Uses of Turbojet Engine

Turbojet engines are primarily employed in high-speed flying aircraft. Particularly, military aircraft such as fighter jets extensively adopt this engine. Additionally, the technology of turbojet engines finds applications in space exploration and missile development.

In flights below supersonic speeds, turbojet engines exhibit drawbacks such as loud exhaust noise, inefficient propulsion, and high fuel consumption. Consequently, they are predominantly used in military aircraft, disposable guided missiles, and as auxiliary engines for vertical take-off and landing aircraft designed for vertical flight.

Principle of Turbojet Engine

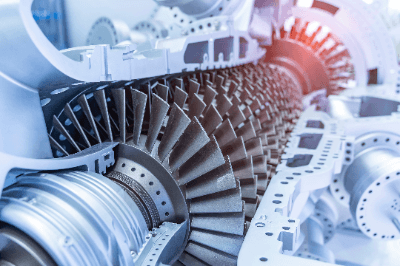

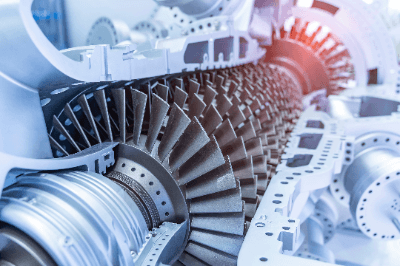

The principle of a turbojet engine involves the intake of air, compression, mixing with fuel for combustion, generating high-temperature, high-pressure gases, and expelling them through an exhaust turbine at high speed to generate thrust. Initially, air is taken in through the engine’s intake at the front. Subsequently, the compressed air is directed to the combustion chamber.

In the combustion chamber, fuel injected from the fuel injection system combines with compressed air and undergoes combustion through an ignition device. The resulting high-temperature, high-pressure gas passes through the exhaust turbine and is jetted rearward from the engine.

The exhaust turbine converts the energy of the high-temperature, high-pressure gas into rotational energy, driving the compression turbine. The gas that passes through the exhaust turbine is ejected at high speed through the nozzle, creating thrust for the aircraft through the reaction force. This is the fundamental principle of a turbojet engine.

Because the gas expelled from the rear of the engine is extremely powerful, it yields higher thrust. With the presence of afterburners (injecting fuel into the high-temperature exhaust gas for re-ignition), turbojet engines are employed in engines for supersonic passenger planes and jet fighters requiring supersonic travel.

Other Information on Turbojet Engine

1. Types of Gas Turbine Engines

In addition to turbojet engines, there are other types of gas turbine engines, including turbofan engines, turboprop engines, and turboshaft engines. Among these, engines that generate a jet stream (jet) and utilize its reaction for thrust are turbojet engines and turbofan engines.

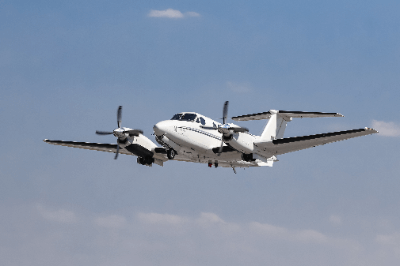

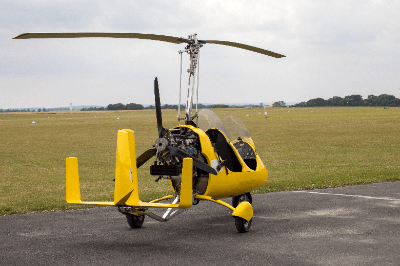

Turboprop engines rotate a propeller by the rotation of the turbine and derive thrust, making them suitable for engines in propeller-driven aircraft. Turboshaft engines convert the rotation of the turbine into shaft rotation, mainly used as the power for the main rotor of helicopters.

2. Turbofan Engine

A turbofan engine has a structure where a fan is added to the front of the compressor in a turbojet engine. Turbofan engines have a structure resembling the incorporation of a turbojet engine inside a turboprop engine, where the diameter of the propeller in turboprop engines is reduced.

In turboprop engines, the airflow resulting from the rotation of the propeller is purely utilized as thrust. In contrast, in turbofan engines, the air in the outer circumferential part, larger than the diameter of the compressor, does not pass through the compressor.

The flow of air through the compressor creates a high-temperature, high-speed jet stream through the core engine, the turbojet engine. The airflow not passing through the compressor becomes a low-temperature, low-speed jet stream. Eventually, these flows mix, resulting in the equalization of jet stream speeds. This leads to an increase in the amount of jet stream, and consequently, an improvement in output compared to turbojet engines.