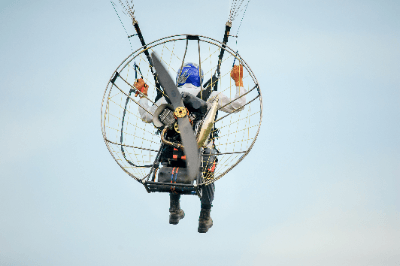

What Is a Hang Glider?

A Hang Glider is an unpowered aircraft designed for competitive or recreational flying, relying solely on the lift generated by its wing.

It consists of a large triangular wing, a glider section with a control bar, and a harness connecting the pilot to the glider. Hang gliders take off by launching from hills or mountains with varying elevations, utilizing wind currents for gliding.

The term “hang glider” originates from the pilot being suspended beneath the wing while gliding through the air, combining the elements of being “hung” in the air and gliding like an aircraft.

Uses of Hang Glider

Hang gliders are often used for recreation or in competitive sports. In recreational settings, especially in picturesque mountainous or coastal areas, individuals can enjoy flying while appreciating the natural scenery.

Hang glider competitions include cross-country events and pylon racing. Cross-country competitions involve determining how far pilots can fly from the starting point, competing based on the distance covered. Impressive long-distance flights of over 700 km and durations extending up to 9 hours have set world records.

Pylon racing competitions, on the other hand, involve setting up a flight course with predetermined points. Participants fly the same course, competing to achieve the fastest flight time from the starting point to the finish line.

Principles of Hang Gliding

Hang gliders achieve flight through the balance of lift, generated by the forces of gravity and wind, pushing the glider upward. With a triangular wing, air flowing over the wing creates lift.

By running into the wind, hang gliders gain lift from the force of the wind, allowing them to become airborne. Once airborne, pilots use their body weight to control the glider. Using a control bar, pilots tilt the hang glider, changing the direction, and can navigate by riding rising air currents.

Unlike conventional aircraft, hang gliders lack a landing gear system. Pilots rely solely on their bodies for takeoff and landing. Consequently, hang gliders are relatively lightweight, typically ranging from 20 to 45 kilograms.

Structure of Hang Glider

The structure of a hang glider comprises two main components:

1. Glider

The glider is divided into the wing and the control bar. The wing consists of a framework made from aluminum alloy or carbon fiber-reinforced plastic, covered with a fabric made of polyester synthetic fibers. The wing’s strength is maintained by battens—narrow pipes or wires.

The control bar is typically made of aluminum alloy or carbon fiber-reinforced plastic and is attached to the center part of the wing, extending downward.

2. Harness

The harness is the component connecting the pilot to the glider. It secures the pilot near the center of gravity of the hang glider. Harnesses can cover only part of the body or the entire body and are connected to the glider using carabiners or similar devices. Additionally, a reserve parachute is often stored in the harness for emergencies.

Other Information on Hang Glider

1. Qualifications for Hang Gliding

To engage in hang gliding, individuals must first register with the Japan Hang & Paragliding Federation (JHF). For safe flying, the JHF has established a skill certification system, and in certain flight areas, carrying the skill certification and registration is mandatory.

To obtain a skill certification, individuals must enroll in a hang glider school, complete the curriculum outlined by the JHF, register as a flyer, and pass the skills examination.

2. Costs for Hang Gliding

Engaging in hang gliding incurs various costs, including license acquisition fees, equipment expenses, activity costs, and maintenance and management fees. Training fees for obtaining a license range from tens of thousands to hundreds of thousands of yen.

Equipment costs, which are the highest, include the glider, harness, helmet, parachute, radio equipment, and other necessary items, totaling around 700,000 yen for budget-friendly options.

Activity costs cover expenses for flights, which depend on the distance to flight locations and accommodation expenses. These costs amount to approximately 30,000 yen but can be reduced to less than 10,000 yen if camping or staying in a tent.

Maintenance and management costs, incurred even when not flying, include fees for storing the aircraft, area registration, and flyer registration, totaling around 50,000 yen annually.

Considering all expenses, engaging in hang gliding requires a substantial financial commitment.