What Is a Low Temperature Incubator?

A low temperature incubator is a device that can control the inside of a chamber at a constant low temperature. It is also called a low-temperature incubator, a low-temperature tester, or a low-temperature incubator. The temperature that can be controlled varies slightly depending on the product, but it can be set between -15°C and 60°C.

A low temperature incubator is a device that can control the inside of a chamber at a constant low temperature. It is also called a low-temperature incubator, a low-temperature tester, or a low-temperature incubator. The temperature that can be controlled varies slightly depending on the product, but it can be set between -15°C and 60°C.

Low temperature incubators with programmable functions can incorporate multiple patterns of time and temperature control. They are used in a wide range of fields for operations and processes that require temperature control, and are used for quality control, experimentation, and testing, in addition to culture and storage.

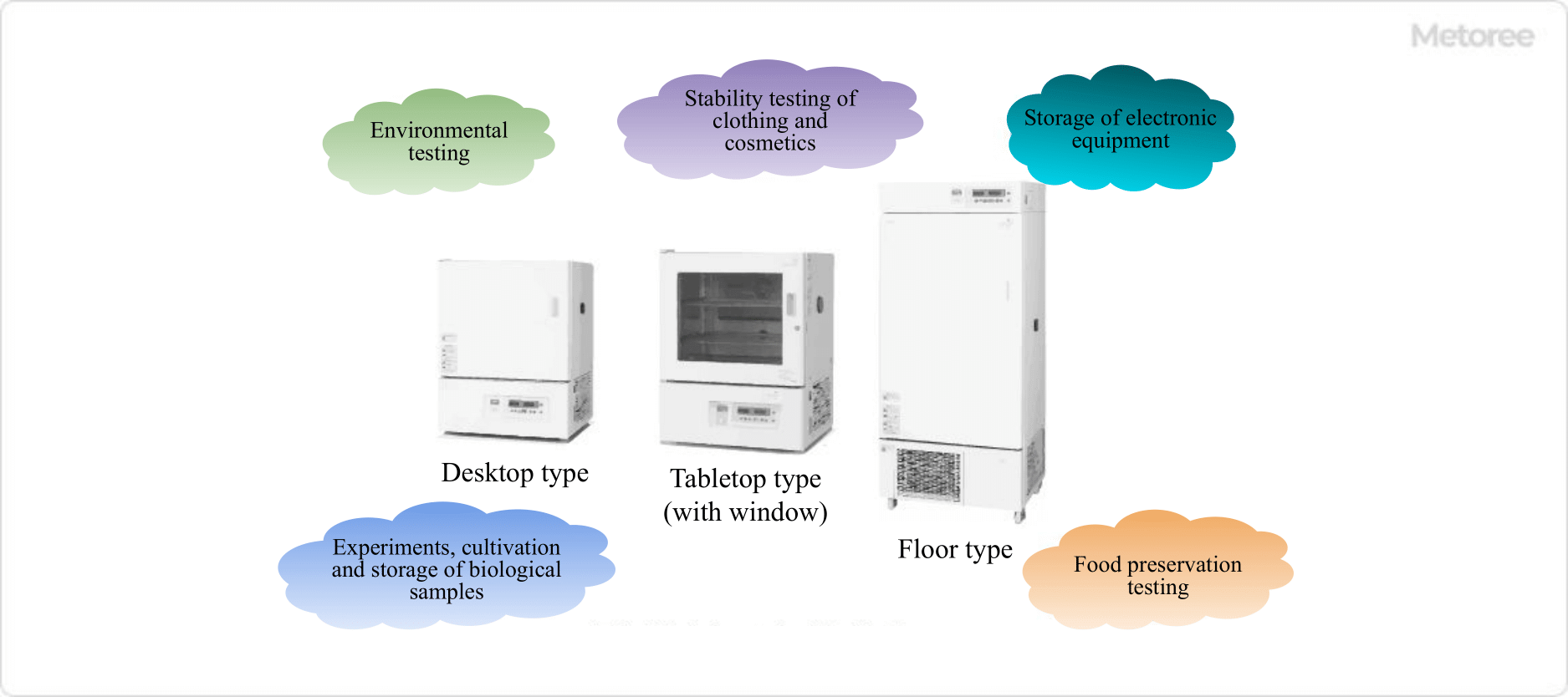

Figure 1. Overview image of the cryogenic incubator

Uses of Low Temperature Incubators

Low temperature incubators are used in many fields, including institutions that handle electronic components, food, precision instruments, and living organisms.

They are used when a constant low-temperature environment is required. Specific uses of low-temperature incubators include tests and experiments at low or constant temperatures, such as plant germination experiments and environmental tests, storage of parts requiring precision control such as electronic equipment, and culture and storage of bacteria and microbes in the physiological field.

In the food field, it is used for strict preservation tests related to HACCP food hygiene management methods and ISO 22000 certification. It is also used for long-term continuous stability testing of pharmaceuticals and cosmetics.

Principle of Low Temperature Incubators

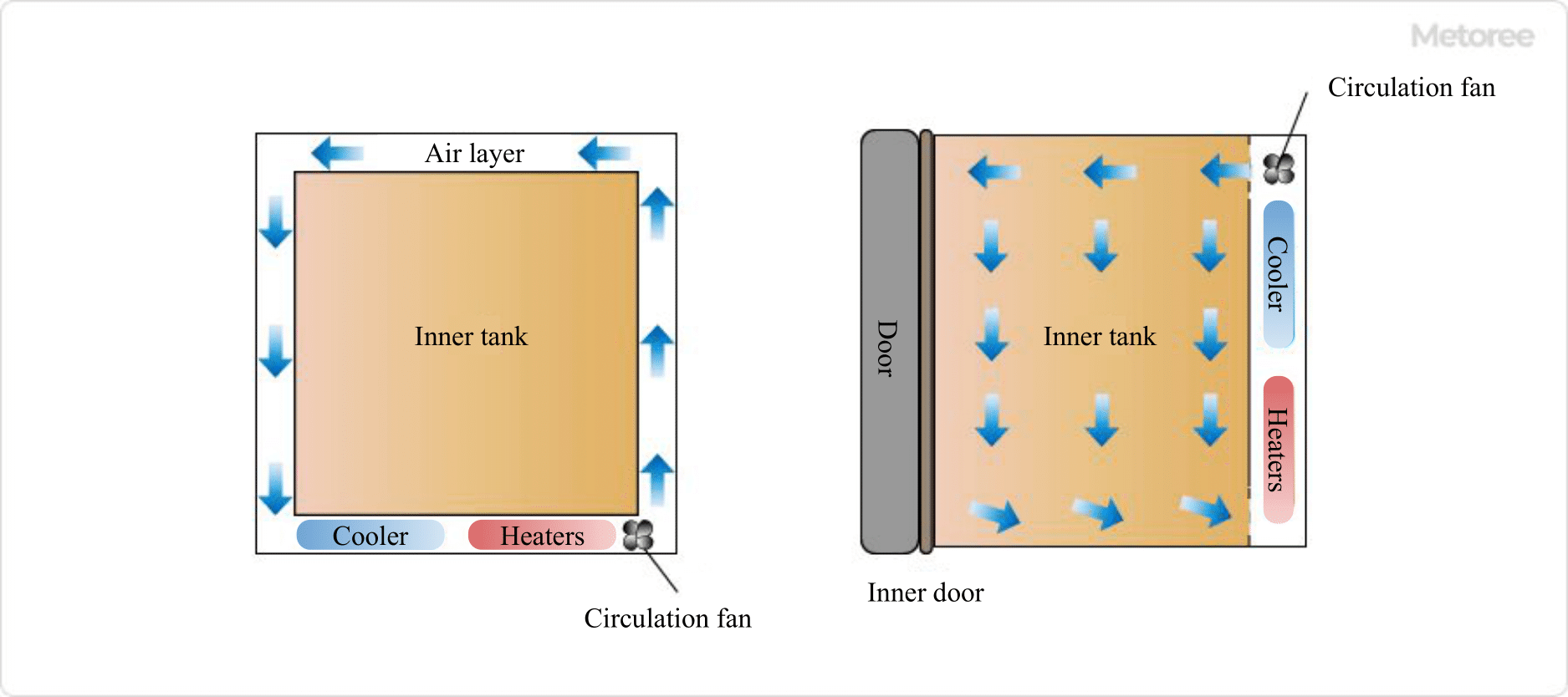

There are two main methods by which low temperature incubators maintain a constant temperature inside the tank. One is the “air circulation method,” which circulates air inside the tank, and the other is the “air jacket method,” which controls the temperature by air flow created from outside the layers by means of a jacket.

- Air Circulation System

In the air circulation method, a fan mounted inside the chamber rotates to stir the air inside the chamber and send airflow to keep the temperature inside the chamber uniform. - Air Jacket System

The air jacket system controls temperature from the outside without creating airflow inside the cabinet. In addition, by periodically changing the direction of the refrigerant, frost formation is prevented due to prolonged operation, allowing for uninterrupted, continuous use.

Cooling systems include those using hydrofluorocarbon (HFC) refrigerants, as well as those using Peltier elements. Although frost tends to form on the cooler during long-term use, some products utilize inverter control to improve frost formation and reduce the need for periodic defrosting (defrosting with hot gas).

Figure 2. Front view of air jacket system / Figure3. Side view of air circulation system

Types of Low Temperature Incubators

The applications for low temperature incubators are very diverse, but it is important to select the right one for your application, as the detailed specifications vary from product to product. The following are examples of points to check when selecting a product.

1. Temperature Range

There are several temperature ranges alone, such as -10~+50°C, 0~60°C, -20~+85°C, and so on. For example, when conducting food preservation tests, it is necessary to select products for room temperature (10 to 35°C), refrigeration (0 to 10°C), and freezing (-15°C or lower). Also, it should be noted that the accuracy of temperature distribution varies from product to product, ranging from ±0.3°C to ±2°C.

2. Size

They come in a variety of sizes, from tabletop models to floor models. Choose a low-vibration product if vibration is a concern, or a product with a full range of program functions if you want to set detailed operation programs.

3. Safety-Enhancing Features

If safety is important, choose a product with an automatic overload protection function, an overload protection device, or an overcurrent leakage breaker.

For long-term continuous testing, it is safer to choose a product that is manufactured to operate for long periods of time. Some products are equipped with two independent refrigeration circuits in case of trouble. If high-precision testing is required, the accuracy of calibration at the time of installation should also be taken into consideration.