What Is a Pressure Sensor?

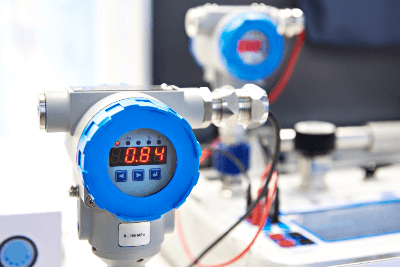

A pressure sensor is a device that measures the pressure of a gas or liquid. The measuring section converts change caused by pressure into an electrical signal and outputs the pressure. The typical measuring part is a gauge type.

Semiconductor gauges, strain gauges, and thin metal films are used for gauge-type pressure sensors. Some types can be set to atmospheric pressure, absolute pressure, or an arbitrary standard for the pressure at the time of measurement.

Uses of Pressure Sensors

Pressure sensors are used in many industrial processes to measure pressure in piping and equipment.

It is necessary to select an appropriate pressure sensor in consideration of the pressure range, the type of gas or liquid to be used, the temperature at which it will be used, and its durability. Pressure sensors are used in a variety of applications, as shown below.

- Measuring the pressure of liquids in liquid filling equipment

- Pressure measurement of liquids and gases flowing in pipes in plants

- Pressure measurement for pressure control in equipment that uses substances highly reactive to pressure

- Application to pressure sensor mats

- Applications in automobiles, industrial machinery, aerospace, medicine, etc.

Principle of Pressure Sensors

Gauge-type pressure sensors measure pressure by detecting diaphragm deformation. There are several types of detection methods, such as semiconductor gage type, strain gage type, and metal thin film type.

Four gauge resistors are placed on the surface of the diaphragm, and when the diaphragm is deformed by pressure, the electrical resistance value changes. 4 gage resistors are assembled in a bridge circuit to output the resistance change as a voltage.

1. Semiconductor Gauge Type Pressure Sensors

Semiconductor gauge pressure sensors use a semiconductor itself as a diaphragm and measure pressure using the piezoelectric effect, which is the property of a semiconductor that changes its electrical resistance when it is subjected to pressure. The change in resistance in response to pressure is much greater than in other methods, and the semiconductor pressure sensors are characterized by the high durability of the device because a robust diaphragm can be made.

2. Strain Gage Type Pressure Sensors

In the strain gauge type pressure sensors, a strain gauge is attached to the backside of the diaphragm, and the change in gauge resistance is measured. The strain gauge is a device that measures strain by utilizing the property of a metal that electrical resistance changes when it is deformed.

3. Metal Thin-Film Type Pressure Sensors

The metal thin-film type pressure sensors measure pressure by forming a metal thin-film on a diaphragm and measuring the change in electrical resistance of the deformed metal thin-film due to pressure. They are highly sensitive to strain gauge type and can be used under high temperatures.

4. Pressure Sensors Other Than Gauge Types

In addition to the gauge-type pressure sensors, there are other types of pressure sensors, such as capacitance type, optical fiber type, and vibration types.

The capacitance type detects the capacitance between a fixed electrode and a diaphragm electrode. The amount of displacement of the diaphragm, which deforms in response to changes in pressure, is measured as a change in capacitance and converted to pressure. It is suitable for measuring the pressure of multiple gas types or gas mixtures.

In the optical fiber type, when pressure is applied to the diaphragm, the diffraction grating at the tip of the optical fiber is deformed, and the change in wavelength of the reflected light is measured. It can measure high temperatures and high precision and is used to measure the pressure of molten resin and blood pressure inside the body.

In the vibration type, a transducer is installed in a silicon diaphragm chip, and when the diaphragm is deformed by pressure, the natural frequency of the transducer changes. The change in frequency is detected and converted to pressure. It has features such as high accuracy, high sensitivity, and high resolution.

Pressure Sensors Application Examples

1. Pressure Sensos Mat

One example of a pressure sensor application is a pressure sensor mat. The pressure sensor mat is generally in the form of a thin mat and intended to be laid on the floor, etc.

Examples of applications of pressure sensor mats include the detection of entry into a high-security room or entry into a hazardous area in a factory. If an entrant steps on the pressure sensors mat, the pressure sensors can sound a buzzer or turn on a lamp based on the information it detects.

In addition, by installing pressure sensor mats in rooms of facilities or at the entrances of homes, it is possible to know when a person with dementia is about to leave.

2. Pressure Sensors for Automobiles

Automotive pressure sensors are used as sensors to precisely measure the pressure of liquids and gases to improve fuel efficiency and other factors. Since pressure sensors used in automobiles are compact, highly accurate, and used in harsh operating environments, semiconductor gauge pressure sensors using piezoresistors are widely used.

Automotive pressure sensors are required to operate reliably and accurately over the long term in operating temperatures ranging from -30°C to 150°C, and even exceeding 300°C depending on the location of use. In addition, since diesel engines must compress a mixture of fuel and air at very high pressures, pressure sensors must have the ability to accurately measure pressures as high as 200 MPa.