Qu’est-ce qu’un connecteur antidéflagrant ?

Les connecteurs antidéflagrants sont des connecteurs pour les connexions électriques utilisées dans des environnements explosifs ou dangereux.

Le terme “antidéflagrant” fait référence à une structure qui empêche les explosions ou les flammes. Les équipements antidéflagrants doivent être utilisés dans les usines qui manipulent des gaz explosifs ou des liquides inflammables ou volatils. Les connecteurs antidéflagrants sont conçus pour éviter les étincelles ou les fortes radiations électromagnétiques qui pourraient provoquer une explosion.

Des matériaux spéciaux sont utilisés pour garantir la robustesse et une grande durabilité dans les environnements explosifs. Les connecteurs antidéflagrants doivent respecter des normes et des critères de sécurité spécifiques. Les normes internationales comprennent ATEX (Europe), NEC (États-Unis) et IECEx (International).

Utilisations des connecteurs antidéflagrants

Les connecteurs antidéflagrants sont utilisés dans les usines chimiques, l’industrie minière et l’armée.

1. Industrie manufacturière

Ils sont souvent installés dans des environnements soumis à des gaz explosifs générés lors de la production de produits chimiques et pétroliers. Les connecteurs antidéflagrants assurent des connexions électriques sûres aux équipements électriques et aux appareils de mesure.

2. Industrie minière

Dans l’industrie minière, des gaz et des poussières explosifs peuvent être générés lors des opérations d’extraction et de raffinage dans les mines. Des connecteurs antidéflagrants sont donc nécessaires. Ils servent dans l’éclairage des mines, les systèmes de communication et les commandes de moteurs.

3. Installations militaires

Les installations militaires manipulent souvent des matières explosives. Les connecteurs antidéflagrants sont donc largement utilisés. Pour éviter les accidents et les incendies causés par des substances explosives, un haut niveau de sécurité est requis dans les connexions électriques et les systèmes de communication.

Principe des connecteurs antidéflagrants

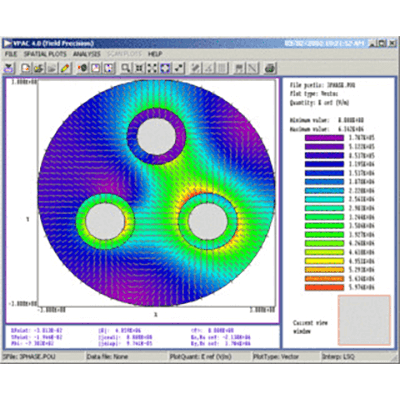

Les connecteurs antidéflagrants sont dotés d’un boîtier étanche qui empêche la pénétration de gaz explosifs et de poussières provenant de l’extérieur. Le boîtier est souvent en acier inoxydable ou en d’autres alliages métalliques.

Ils comportent également des zones de contact pour la transmission des signaux électriques. Ils sont constitués de broches et de douilles métalliques et se caractérisent par la stabilité du signal et une faible résistance de contact. Les parties de contact des connecteurs antidéflagrants minimisent le risque d’explosion, par exemple en utilisant des espaces antidéflagrants.

Ils peuvent également être équipés de dispositifs de blindage pour éviter les interférences électromagnétiques externes et les effets électrostatiques. De plus, les câbles sont souvent mis à la terre au niveau des connecteurs et des connexions de câbles. Cela permet de contrôler les décharges électrostatiques et de réduire le risque d’explosion.

Pour éviter les étincelles et les décharges dues à des connexions incomplètes, des mécanismes de verrouillage sont souvent prévus. Si le connecteur n’est pas connecté correctement, le circuit électrique est interrompu, ce qui garantit la sécurité.

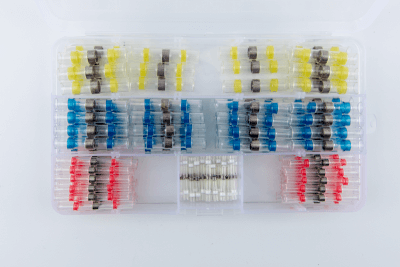

Types de connecteurs antidéflagrants

Les performances antidéflagrantes des connecteurs antidéflagrants sont spécifiées dans les normes nationales et internationales. Ils sont également classés de la zone 0 à la zone 2 par ordre de danger croissant en fonction du type et de la quantité de matières dangereuses manipulées. La construction antidéflagrante requise pour chaque zone est spécifiée.

Les quatre principaux connecteurs antidéflagrants utilisés sont : les connecteurs antidéflagrants à sécurité intrinsèque, les connecteurs antidéflagrants contre la pression, les connecteurs antidéflagrants contre la pression interne et les connecteurs antidéflagrants à sécurité accrue.

1. Connecteurs antidéflagrants à sécurité intrinsèque (Symbole i)

Cette structure ne constitue pas un point d’ignition pour des espaces explosifs en cas d’étincelles ou de températures élevées pendant le fonctionnement normal et les dysfonctionnements.

Dans les zones 0, les équipements difficiles à rendre intrinsèquement sûrs, tels que les panneaux de commande, sont souvent installés en dehors de la zone antidéflagrante. Des connecteurs antidéflagrants sont utilisés pour les connexions électriques à partir de l’armoire de commande.

2. Connecteurs antidéflagrants contre la pression externe (Symbole d)

Il s’agit d’une structure étanche qui résiste à la pression d’une explosion externe sans risque d’inflammation supplémentaire. Des boîtiers métalliques robustes sont utilisés et ils sont classés zone 1.

3. Connecteurs antidéflagrants contre la pression interne (Symbole f)

Une structure dans laquelle un gaz protecteur est scellé à l’intérieur pour éliminer le risque d’inflammation. L’azote est utilisé comme gaz de stockage.

4. Connecteurs antidéflagrants à sécurité renforcée (Symbole e)

Une structure avec des mesures de sécurité pour éviter les étincelles, les arcs électriques et les températures élevées. Ils peuvent être considérés comme étant de zone 3.