What Is a Halogen Lamp?

A halogen lamp is a type of incandescent lamp that contains trace amounts of halogen elements (iodine, bromine, etc.) in addition to inert gases such as nitrogen and argon.

Halogen lamps emit light in the same way as ordinary incandescent lamps, by passing electricity through a filament inside the bulb. The filament is a thin, thread-like metal wire, most often made of tungsten, which has the highest melting point of all metals (3,422°C).

Uses of Halogen Lamps

1. Lighting

Halogen lamps are used for spotlighting on product shelves, floodlighting, car headlights, studio and stage lighting, and other applications because of their compact size, high luminance, easily adjustable light distribution (light spread), and good color rendering properties (colors are close to those seen in sunlight). However, with the spread of LED light sources, opportunities for use in lighting applications are decreasing.

2. Projectors

Halogen lamps have been used as light sources for OHPs and slide projectors used in schools, etc. Today, LED and laser light sources are becoming the mainstream.

3. Light Source for Spectroscopic Analysis

Light sources for spectroscopic analysis are used because they have a constant brightness over a wide range of wavelengths and little fluctuation in intensity over time.

4. Heater

The fact that the majority of the energy radiated is infrared tells us that halogen lamps as light sources are inefficient but excellent heaters. Therefore, halogen lamps have applications in a variety of situations requiring localized heating, such as heat retention, heat treatment, drying, and high-temperature molding of food and materials, in addition to localized heating indoors and outdoors.

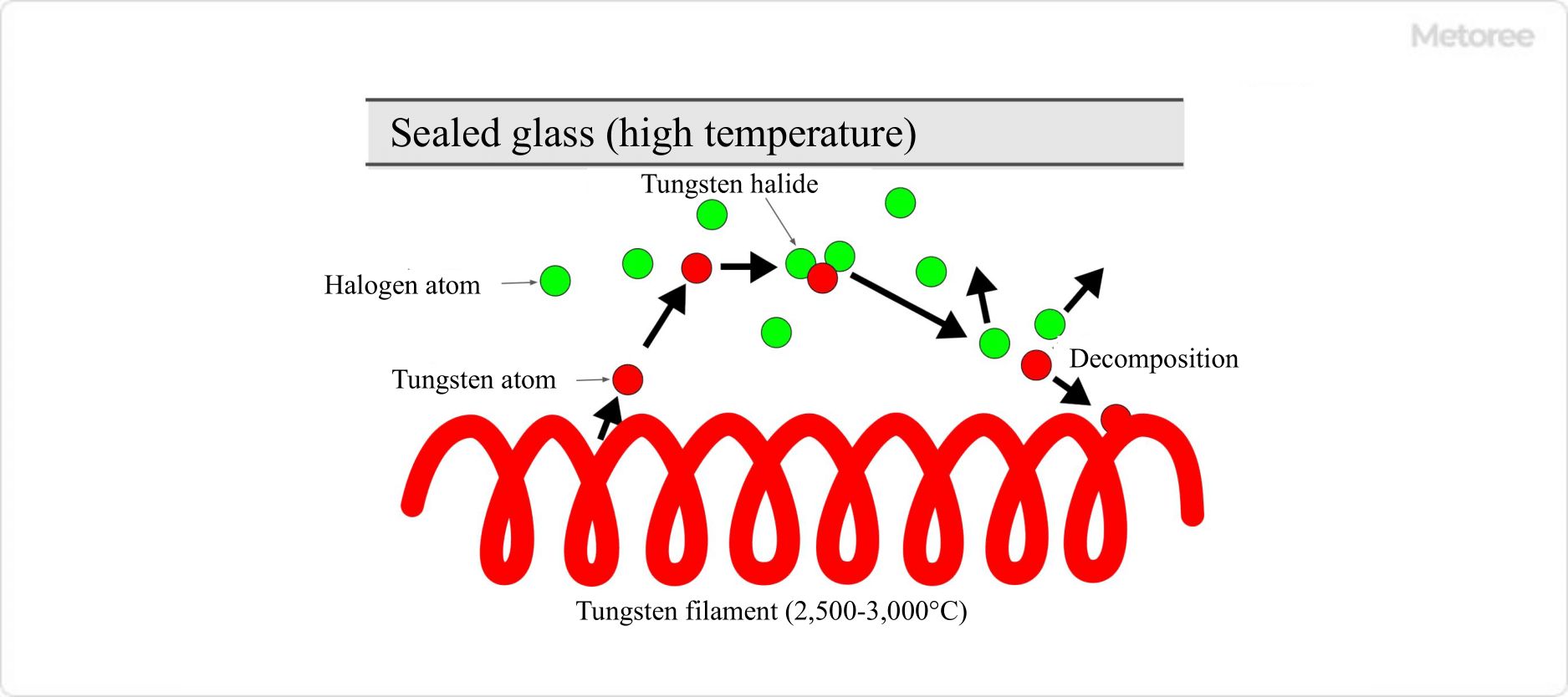

Principle of Halogen Lamps

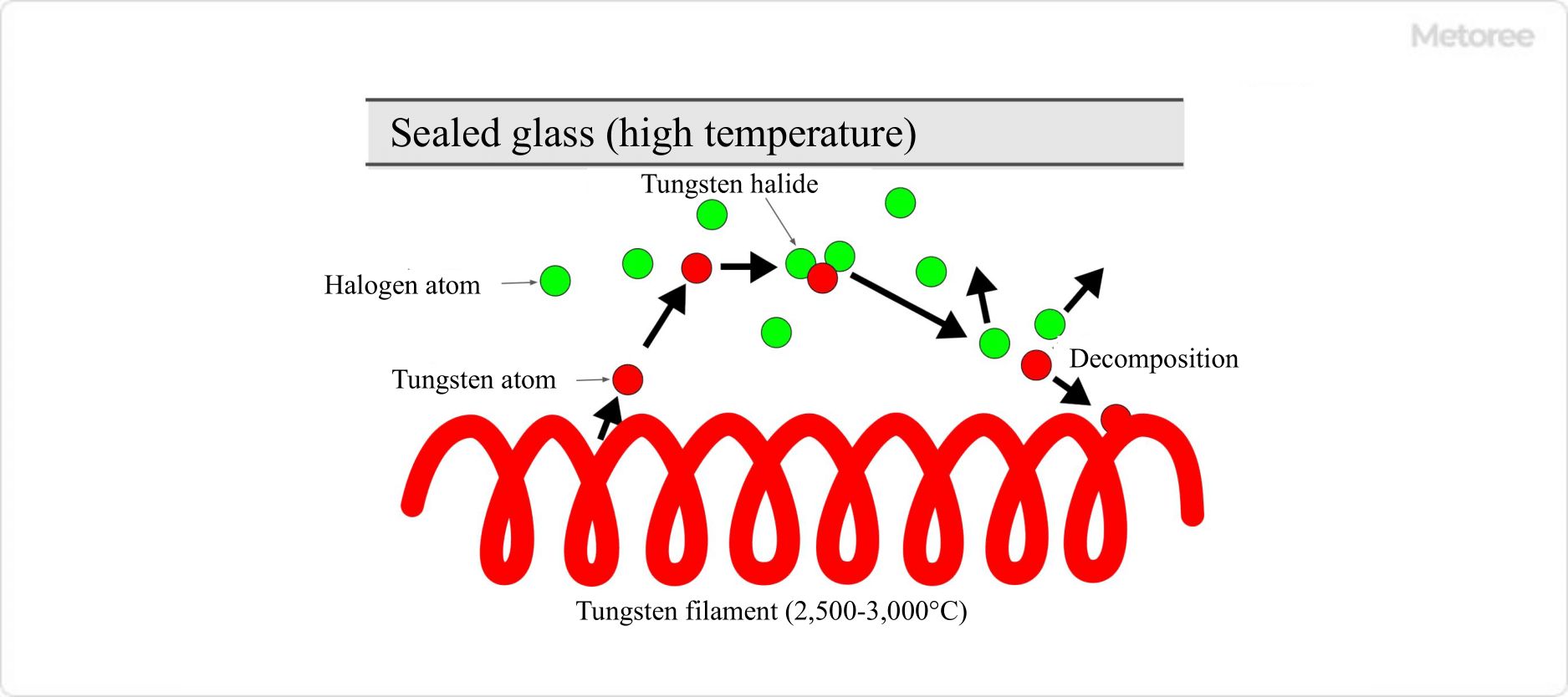

The filament temperature of ordinary incandescent lamps ranges from 1,500 to 3,000°C, while that of halogen lamps is usually as high as 2,500 to 3,000°C, with special ones reaching as high as 3,300°C. Therefore, a small amount of tungsten is constantly evaporating on the surface of the filament.

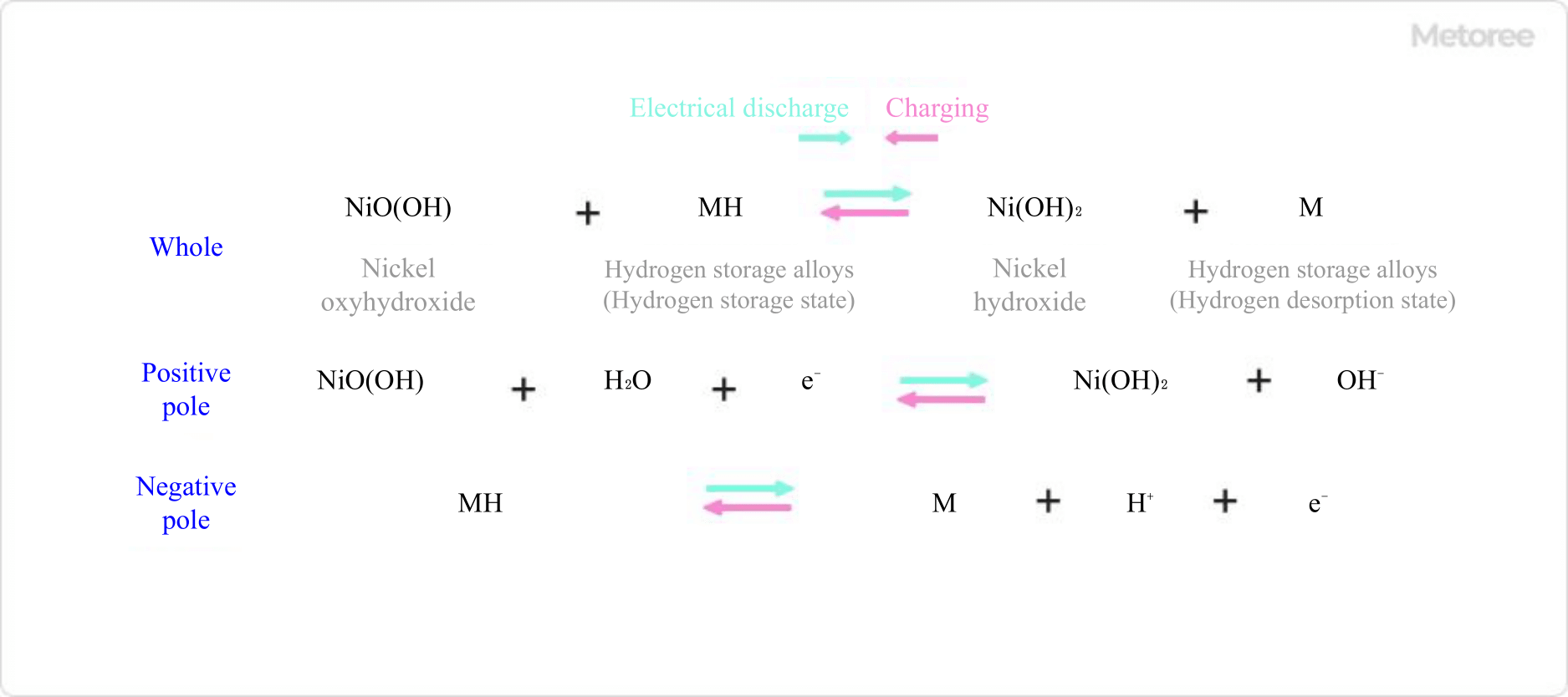

Figure 1. Halogen Cycle

To suppress the blackening phenomenon, halogen lamps contain a small amount of halogen elements along with inert gas in the bulb. In this way, if conditions such as temperature and materials are appropriate, the blackening phenomenon will not occur due to the halogen cycle that occurs in the lamp.

The halogen cycle is a phenomenon that occurs in the following manner.

- Tungsten atoms evaporate and diffuse from the hot filament during lighting.

- Halogen gas reacts with the evaporated tungsten to form tungsten halide.

- If the glass wall is hot enough (>170°C for iodine halogen), tungsten halide does not adhere to the glass wall.

- When the tungsten halide moves near the hot filament, it decomposes and the tungsten atoms return to the filament.

The halogen cycle prevents filament wear and tungsten-induced blackening of the glass inner wall.

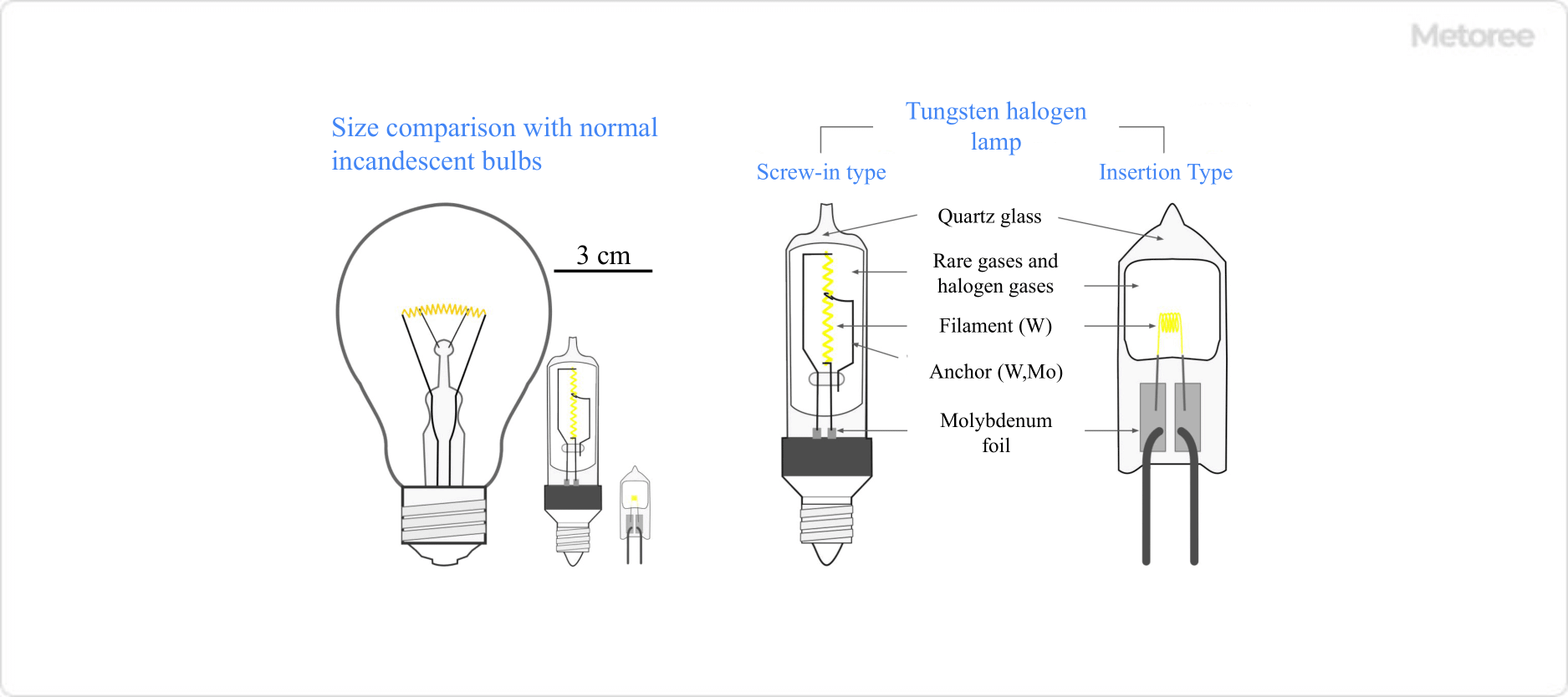

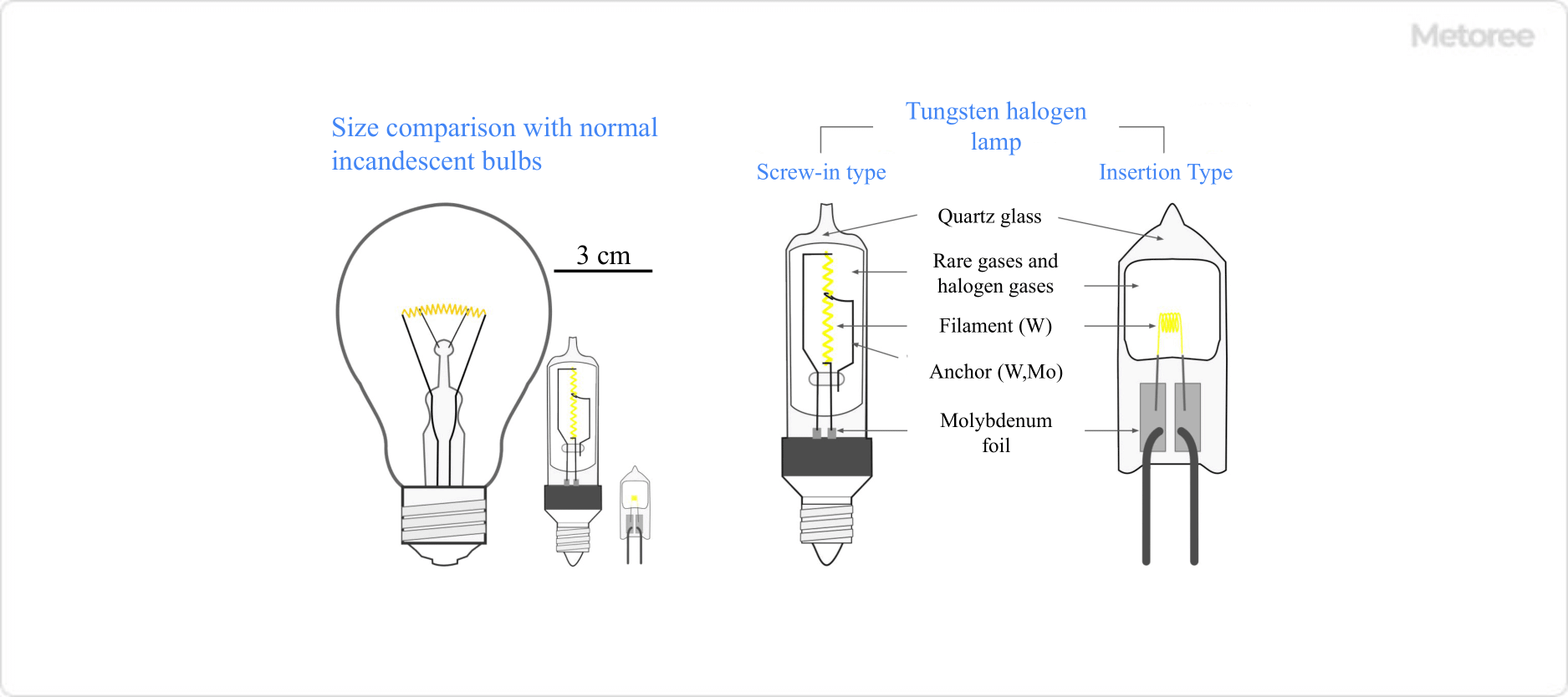

Structure of Halogen Lamps

Figure 2. Incandescent and Halogen Lamps

To achieve a halogen cycle, the encapsulated glass must be kept at a high temperature. When iodine is used as a halogen gas, the glass temperature must be 170°C or higher, and when bromine is used, the glass temperature must be 250°C or higher.

Therefore, quartz glass, which can withstand high temperatures, is usually used, and molybdenum foil is used to electrically connect the inside and outside of the halogen bulb so that the inside remains airtight even at high temperatures.

Other Information on Halogen Lamps

1. Disadvantages of Incandescent Bulbs

In ordinary incandescent bulbs, blackening occurs when evaporated tungsten adheres to the inner wall of the bulb’s glass. As the filament wears out, the luminous efficiency inevitably decreases.

This blackening phenomenon is an obstacle, making it difficult to miniaturize incandescent bulbs with high power consumption or to raise the filament temperature to higher levels to increase brightness and color temperature.

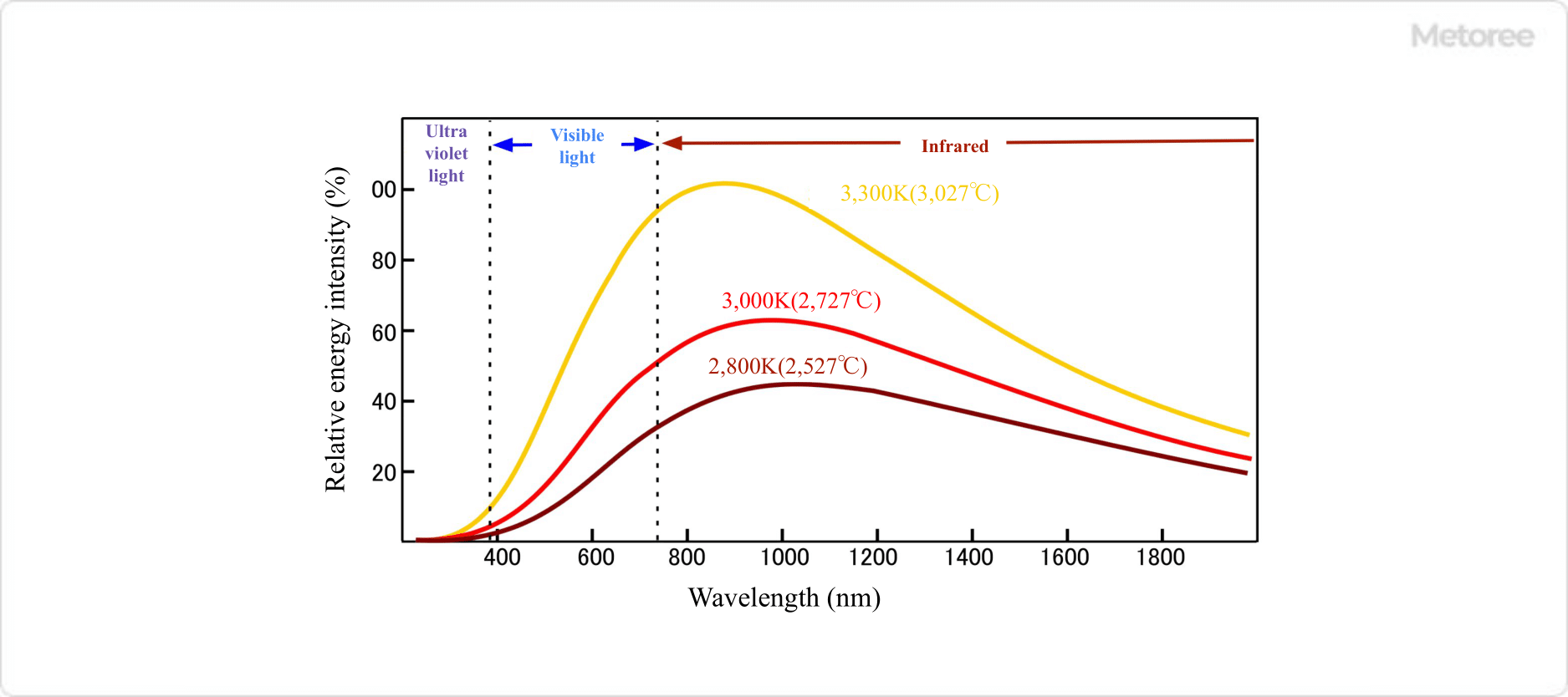

2. Characteristics of Light Emitted From Halogen Lamps

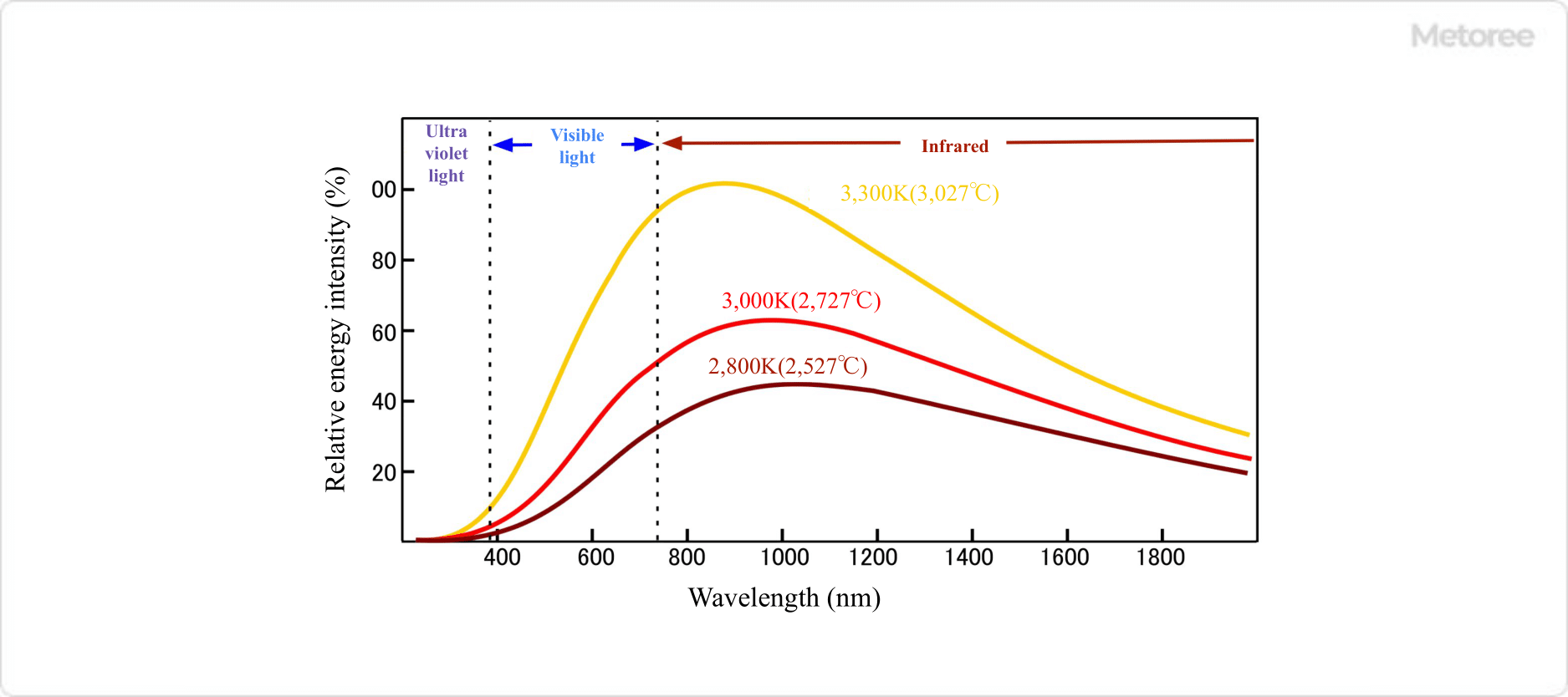

Figure 3. Filament Temperature and Intensity Distribution of Emission Spectrum

The light spectrum emitted from a halogen lamp is almost identical to the blackbody radiation spectrum, which corresponds to the temperature of the filament. Because the temperature of the filament is lower than that of the sun, the emitted light contains almost no ultraviolet light, and its visible light portion has a slightly higher red component, resulting in a warm white light appearance.

The peak of the radiation is in the near-infrared region with wavelengths of 900 to 1,000 nm, and the majority of the radiation is in the visible to near-infrared region with wavelengths of 500 to 3,000 nm.

3. Advantages of Halogen Lamps

Compared to ordinary incandescent lamps, halogen lamps allow a smaller distance between the filament and the encapsulated glass. Also, the temperature of the filament can be higher, which offers various advantages.

- Because of their small size, transportation costs can be significantly reduced.

- Since the blackening phenomenon does not occur, there is almost no decrease in brightness until the end of the life of the product.

- When used at the same filament temperature, the service life can be more than doubled.

- Brightness can be increased by about 30% for the same life setting.

- The use of quartz glass allows the surface temperature to be raised to approximately 900°C (twice as high).

- Quartz glass has high thermal shock resistance and does not break even when heated to 900°C and placed in cold water.

4. Advantages of Halogen Lamps

- Radiant Heat

90% of the power consumption is radiant light that transfers energy directly to the object to be heated, making it suitable for rapid heating.

- Low Heat Loss

Radiant light reaches the object to be heated without being affected by air currents or air temperature, and since the radiation source (filament) is inside the glass tube, it is hardly affected by its surroundings.

- Fast Start-Up

Thermal radiation output reaches 90% of rated output within 1 second after energizing.

- High Energy Density

Small-sized halogen lamps can maintain a heat generation density of 100 w/cm2 or higher, which allows them to heat objects to 1500°C or higher.

- High Thermal Shock Resistance

The lamp will not be damaged even if water is splashed on it during use.

- Metal Heating

Wavelengths of visible light to near-infrared rays are easily absorbed by metals, making them suitable for heating metals.

- Non-Contact Heating

Does not contaminate the object being heated or the surrounding environment. Heating of a sample in a separate room is also possible through a glass window, etc.

- Optical Control

A reflective mirror or similar device can be used to precisely spot-heat a targeted area.