What Is a Color Sensor?

A color sensor is a specialized device designed to accurately distinguish the colors of objects.

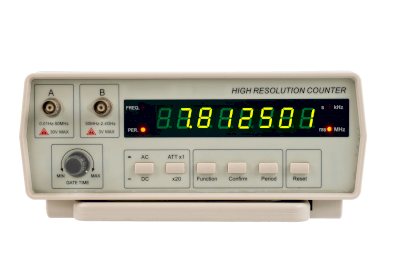

It operates by detecting the wavelength and color of light reflected from or transmitted through objects, converting this optical information into electrical signals. Typically, color sensors are used to analyze reflected or transmitted light from a light source, providing precise color or light-related data.

Color sensors are renowned for their ability to deliver highly accurate color measurements. They excel at detecting even subtle color changes or anomalies, making them invaluable for quality control and optimizing manufacturing processes. Furthermore, their real-time color processing capabilities make them well-suited for high-speed production lines and various application systems.

An important advantage of color sensors is their non-contact operation. In industrial manufacturing, this feature minimizes the impact on product quality.

However, it’s essential to note that ambient lighting conditions can significantly affect color sensor performance. Variations in lighting type and intensity can lead to fluctuations in measurement results, underscoring the importance of maintaining appropriate lighting conditions.

Uses of Color Sensors

Color sensors find applications in diverse fields where precise color detection is essential. Here are some notable examples of how color sensors are utilized:

1. Manufacturing Industry

In the manufacturing industry, color sensors play a pivotal role in quality control. For products with painted surfaces, color sensors assess the color of the paint to ensure it matches the specified color. This consistency is crucial for delivering high-quality products that meet customer expectations.

Color sensors are also frequently employed in the production of molded plastic items to verify color consistency. Additionally, they are integral in the display manufacturing sector, where they analyze ambient light to correct display colors and enhance image quality on devices such as smartphones and tablets.

2. Medical Applications

In the medical field, color sensors serve multiple purposes. They are used to measure skin color and blood oxygenation levels. Changes in skin color can be indicative of circulatory disorders or skin conditions, making color sensors valuable diagnostic tools.

Furthermore, in dentistry, color sensors are used to measure and match tooth color. This is particularly useful for aesthetic treatments and ensuring proper color matching for dental prosthetics.

3. Printing Industry

The printing industry relies heavily on color sensors for quality control. These sensors are essential for maintaining color consistency in printed materials.

Color sensors integrated into printing presses continuously monitor the color of printed materials and make real-time color adjustments as needed. This process enhances color reproduction and ensures consistency across different print jobs.

Principle of Color Sensors

The core principle behind color sensors involves illuminating objects with red, blue, and green light and detecting which wavelengths of light are absorbed and to what extent. When red, blue, and green light are directed at a red object, such as an apple, only the red light is reflected, while the blue and green light is absorbed.

Consequently, only the reflected red light reaches our eyes, causing the apple to appear red. Conversely, when all three colors of light strike a white object, all wavelengths are reflected, resulting in the object appearing white.

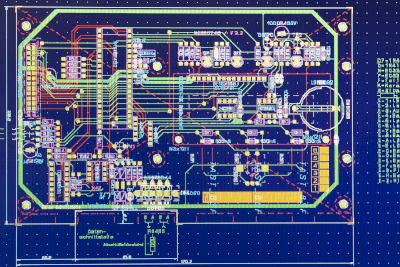

The internal structure of a color sensor can be broadly divided into three components: the light emitter, the light receiver, and the processing circuit. The light emitter emits light onto the object under examination to gauge the intensity of reflected light.

The ratio of red, blue, and green light detected by the light receiver is employed to determine the color. The light-receiving component converts this ratio into an electrical signal, which is then processed by the circuitry for color identification.

How to Select a Color Sensor

When choosing a color sensor, it’s essential to consider various factors to ensure it suits the intended application. Key considerations include:

1. Detection Distance

The detection distance of a color sensor represents the maximum range at which the sensor can accurately detect colors. Selection should align with the specific requirements of the application, with longer detection distances being necessary for covering larger areas.

2. Output Type

Color sensors offer different output types, including analog and digital signals. Analog output provides continuous measurement data, while digital output switches signal when a predefined threshold is reached. Additionally, some color sensors offer serial communication outputs. The choice depends on the application’s needs.

3. Connection Method

Consider the connection method between the color sensor and the control device. Common connection options include connectors, terminals, and others. Opt for a method that seamlessly integrates with the control device.

4. Protective Structure

For environments with specific requirements, the protective structure of a color sensor is crucial. Factors like dustproof and waterproof capabilities are often indicated by IP codes, which consist of two numbers, with the first denoting dustproofness and the second indicating waterproofness.