What Is a Signal Relay?

Signal relays are components for electric circuits that turn on and off electrical signals of relatively low current.

Products that open and close signals of about 2A or less are common.

Uses of Signal Relays

Signal relays are used to switch electrical signals on and off. They are used in products that have electric circuits and have a wide range of applications, from home appliances to industrial equipment.

Specific applications are as follows:

- Home-use TV remote controls

- Inside control boards used in air conditioners and refrigeration units

- Inside control boards for hot water heaters

- Inside control boards for industrial robots

- Inside control boards for PCs

Mainly used by mounting on control boards. However, some products are available with an optional dedicated socket for mounting on the DIN rail of the control panel.

Principle of Signal Relays

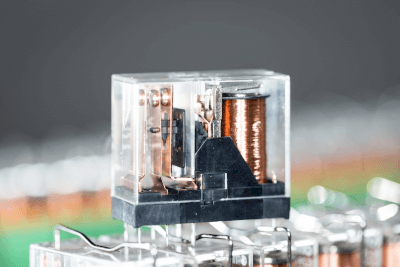

Signal relays consist of a casing, input/output terminals, insulating parts, and contact switching parts.

1. Casing

The casing protects the signal relay. In most cases, it is made of resinous insulating material. It protects human contact with the electrical circuit. In some cases, simple specifications and serial numbers are printed on the casing.

2. Input/Output Terminals

These are terminals for sending and receiving signals. Typical input/output terminals are in the form of pins, with multiple pins protruding from the signal relay. Terminals are inserted into special sockets or soldered to electrical circuits.

3. Insulating Parts

These parts are used to support signals while insulating them. Generally, insulating materials such as resin are used because input/output circuits will be interfered with if supported by metal structures. The shape varies depending on the product.

4. Contact Open/Close Components

These parts open and close contacts based on input signals. The construction of the component varies depending on the type of signal relay. In the case of a contact relay, it consists of a movable iron piece, a contact, an electromagnetic coil, and so on. In the case of non-contact relays, photo couplers and other parts are used as contact open/close parts.

Types of Signal Relays

Signal relays can be classified into two main types according to the type of contact point: contact relays and non-contact relays.

1. With-Contact Relays

Contact relays are relays that actually use electromagnetic coils and springs to open and close electrical contacts. They are also called mechanical relays. Generally, an electromagnetic coil is used to open and close the contacts by moving the movable iron strip to which the contacts are attached.

Silver, which has low electrical resistance, is used as the contact material. Products plated with soft gold to reduce contact resistance are also available. Since contact wear and deterioration of the moving parts occur, the relay is characterized by a life span that depends on the frequency of contact opening/closing.

2. Contactless Relay

A contactless relay is a relay that has no mechanical contacts. They are also called solid-state relays.

Contacts are opened and closed by semiconductor electronic components, such as MOSFETs. Since the contacts do not actually move, there is no residual life, depending on the frequency of contact opening and closing. Therefore, it has a longer life than a contact relay. However, the semiconductor components are sensitive to high temperatures and heat, making them unsuitable for use in high-temperature environments.

Other Information on Signal Relays

Contacts of Signal Relays

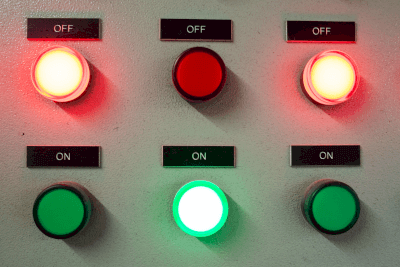

Relay contacts are divided into a-contact, b-contact, and c-contact. Each contact is used separately to configure a control circuit.

1. A-Contact

The A-contact is a contact that is open when no signal is input to the input terminal and conducts when a signal is input. It is also called a normally open contact or a make contact. It is the most common type of contact that provides signal isolation only.

2. B-Contact

The B-contact is a contact that conducts when no signal is input to the input terminal and opens when a signal is input. It is characterized by the opposite action of the A-contact and can invert the input signal. It is often used in interlock circuits and fault interrupting circuits.

3. C-Contact

The C-contact is a three-terminal contact combining a and b contacts. It has three terminals: a common terminal, an A-contact terminal, and a b-contact terminal. When no signal is input to the input terminal, the common B-contact terminal is conducting and the common-a contact terminal is open.

When a signal is input to the input terminal, the common terminal-B contact terminal is open and the common-a contact terminal is conducting. It is used for circuits that switch between forward and reverse rotation. Another feature of the C-contact is that it is applicable only to contact relays.